Main shaft box for gantry engraving and milling machine

A spindle box, engraving and milling machine technology, applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of low torque, low work efficiency, unsuitable for roughing operations, etc., to increase the roughing capacity , small vibration, and the effect of improving the smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

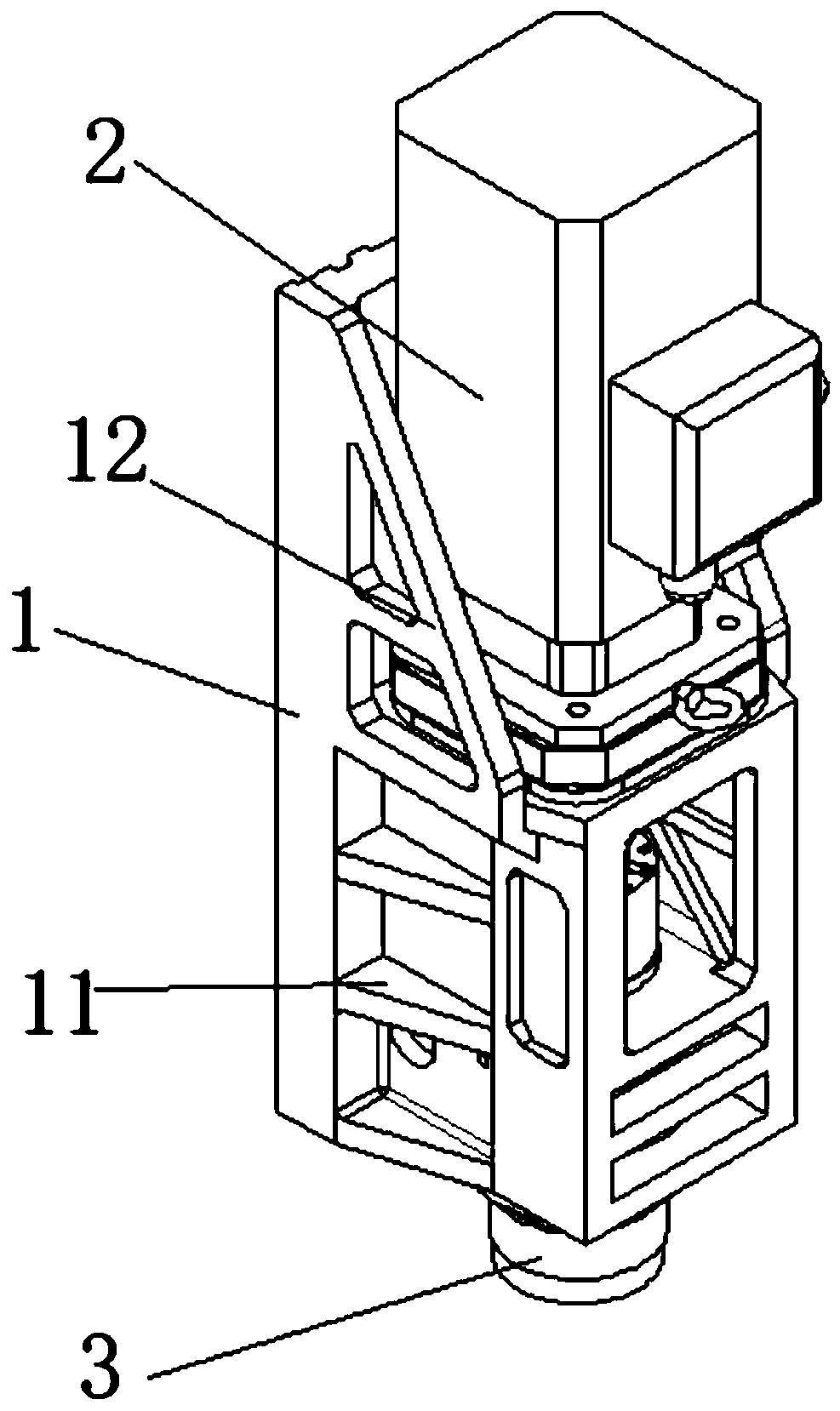

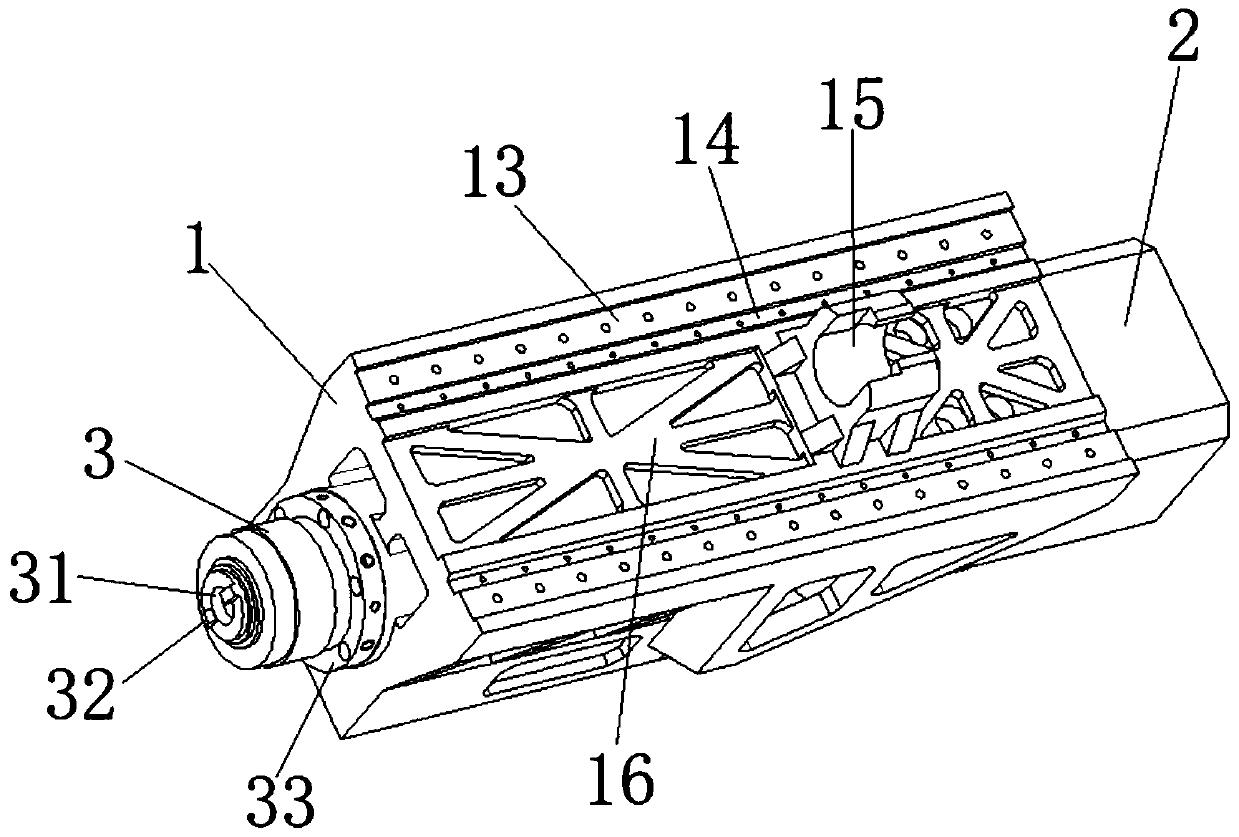

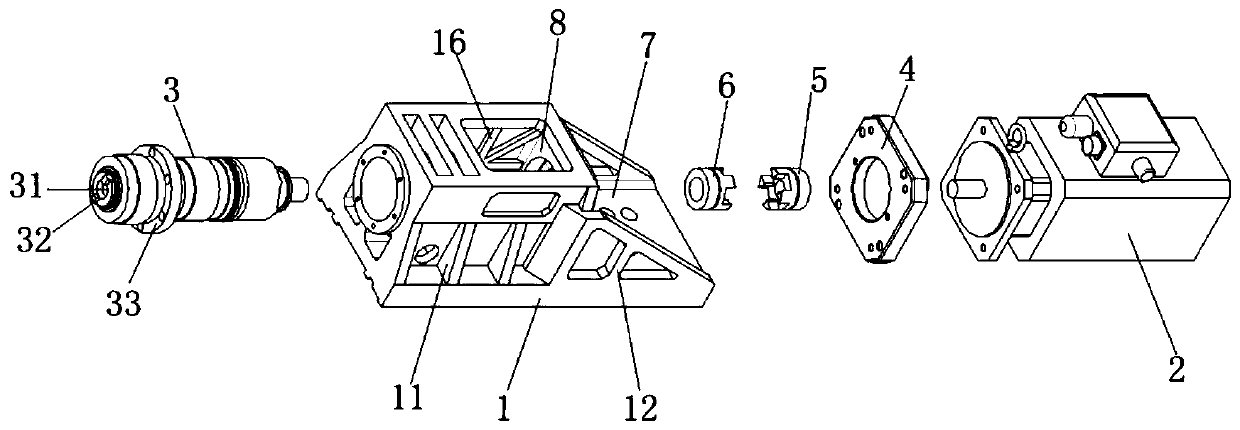

[0019] refer to Figure 1-5 , a spindle box of a gantry engraving and milling machine, including a spindle box 1 slidably connected on the engraving and milling machine door frame, the spindle box 1 includes a hollowed-out motor chamber 7 and a spindle chamber 8, and a guide rail mounting surface 13 arranged on the back of the spindle box 1 , one side of the guide rail mounting surface 13 is symmetrically provided with two guide rail pressing block installation positions 14, and a screw nut seat 15 is fixed between the two guide rail pressing block installation positions 14, and the spindle box 1 is installed in the lead screw nut seat 15 The screw nut assembly and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com