A displacement transmission structure of an inspection robot

An inspection robot and transmission structure technology, applied in the field of inspection robots, can solve the problems of easy noise, high cost, damage to the body, etc., and achieve the effects of prolonging the service life, uniform force points, and free horizontal movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

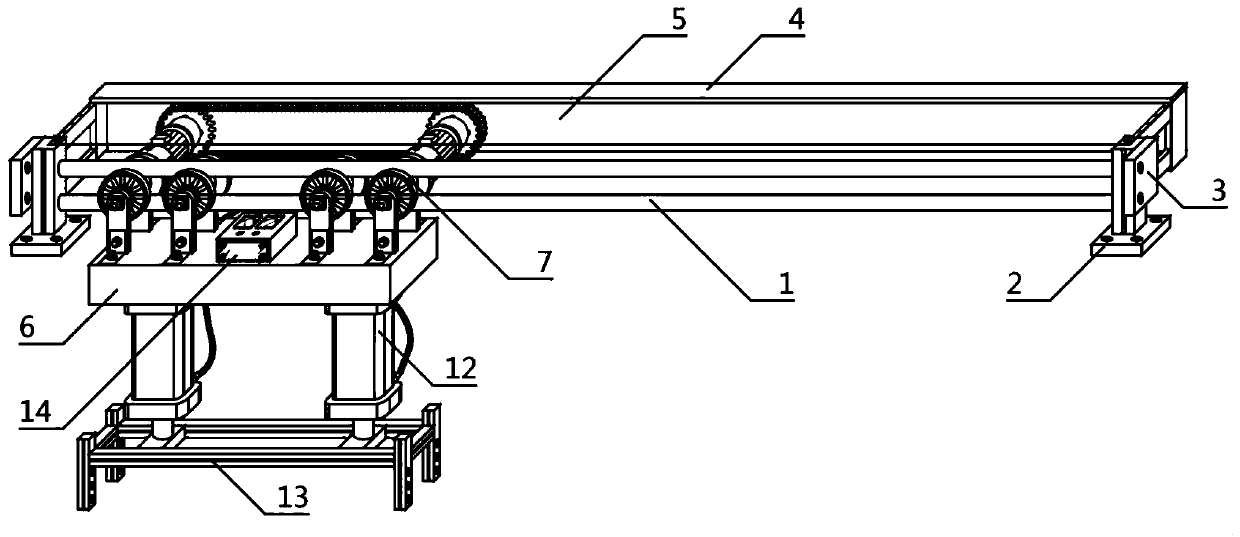

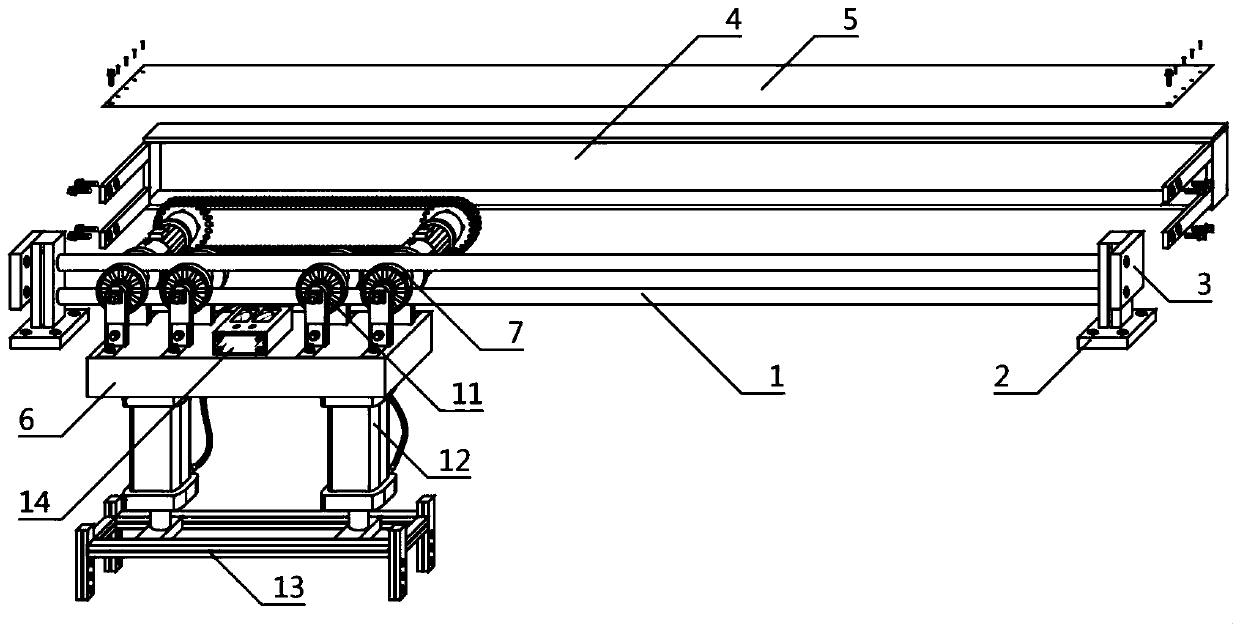

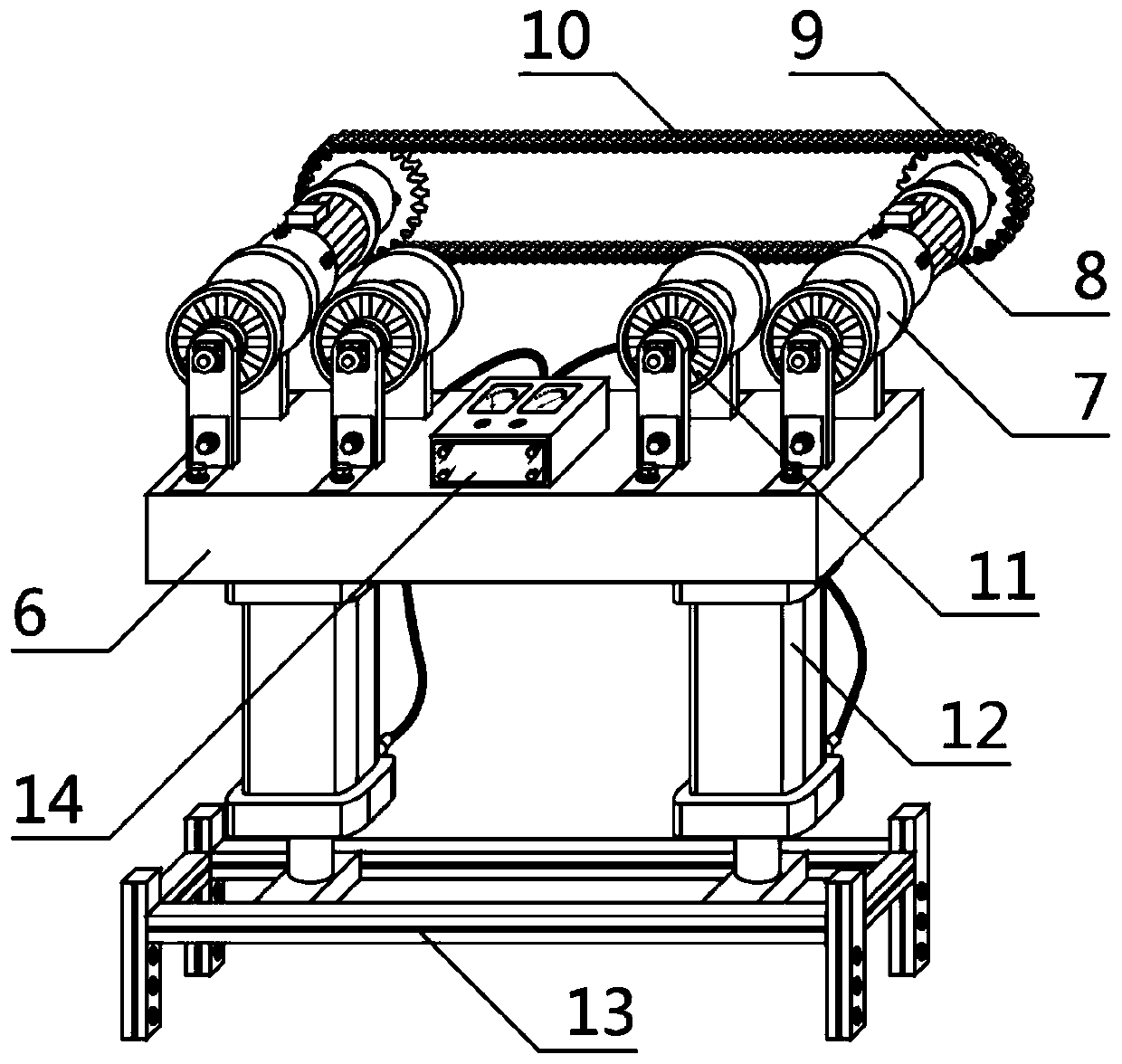

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 A displacement transmission structure of an inspection robot is shown, which is characterized in that: a horizontal rail frame 1, a transmission protection box 4, a horizontal moving frame 6, several driving pulleys 7, several auxiliary positioning pulleys 11, several lifting devices 12, The inspection device fixing frame 13 and the control box 14 are composed, and the horizontal track frame 1 is also provided with several facade fixing plates 2 and several side fixing plates 3, and any of the facade fixing plates 2 is located on the horizontal track frame 1 The lower part of one side, the facade fixed plate 2 is fixedly connected with the horizontal track frame 1, any of the side fixed plates 3 is located at one side of the horizontal track frame 1, and the side fixed plate 3 and the horizontal track frame 1 are fixed connected, the transmission protection box 4 is located on the other side of the horizontal rail f...

Embodiment 2

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 A displacement transmission structure of an inspection robot is shown, which is characterized in that: a horizontal rail frame 1, a transmission protection box 4, a horizontal moving frame 6, several driving pulleys 7, several auxiliary positioning pulleys 11, several lifting devices 12, The inspection device fixing frame 13 and the control box 14 are composed, and the horizontal track frame 1 is also provided with several facade fixing plates 2 and several side fixing plates 3, and any of the facade fixing plates 2 is located on the horizontal track frame 1 The lower part of one side, the facade fixed plate 2 is fixedly connected with the horizontal track frame 1, any of the side fixed plates 3 is located at one side of the horizontal track frame 1, and the side fixed plate 3 and the horizontal track frame 1 are fixed connected, the transmission protection box 4 is located on the other side of the horizontal rail f...

Embodiment 3

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 A displacement transmission structure of an inspection robot is shown, which is characterized in that: a horizontal rail frame 1, a transmission protection box 4, a horizontal moving frame 6, several driving pulleys 7, several auxiliary positioning pulleys 11, several lifting devices 12, The inspection device fixing frame 13 and the control box 14 are composed, and the horizontal track frame 1 is also provided with several facade fixing plates 2 and several side fixing plates 3, and any of the facade fixing plates 2 is located on the horizontal track frame 1 The lower part of one side, the facade fixed plate 2 is fixedly connected with the horizontal track frame 1, any of the side fixed plates 3 is located at one side of the horizontal track frame 1, and the side fixed plate 3 and the horizontal track frame 1 are fixed connected, the transmission protection box 4 is located on the other side of the horizontal rail f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com