Gripping apparatus of tubular pile steel cage

A technology of steel cages and grippers, which is applied in the direction of load hanging components, transportation and packaging, etc., which can solve problems such as desoldering or falling apart, easy deformation of steel cages, unsafety, etc., and achieve labor cost savings, balanced force points, non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

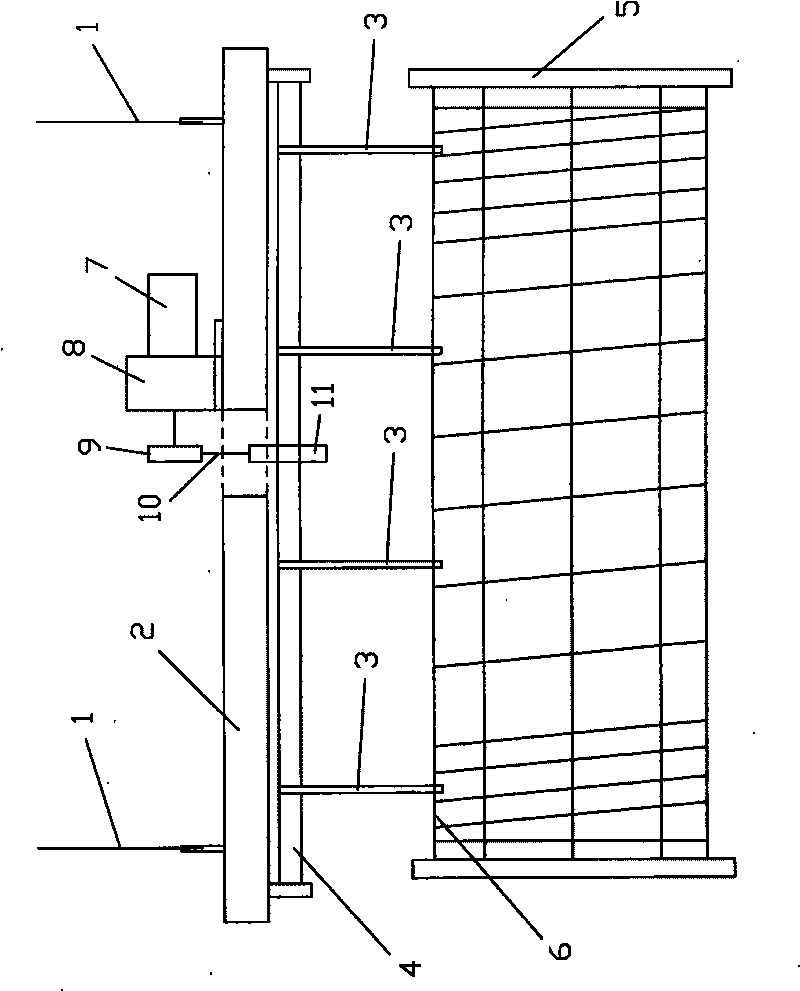

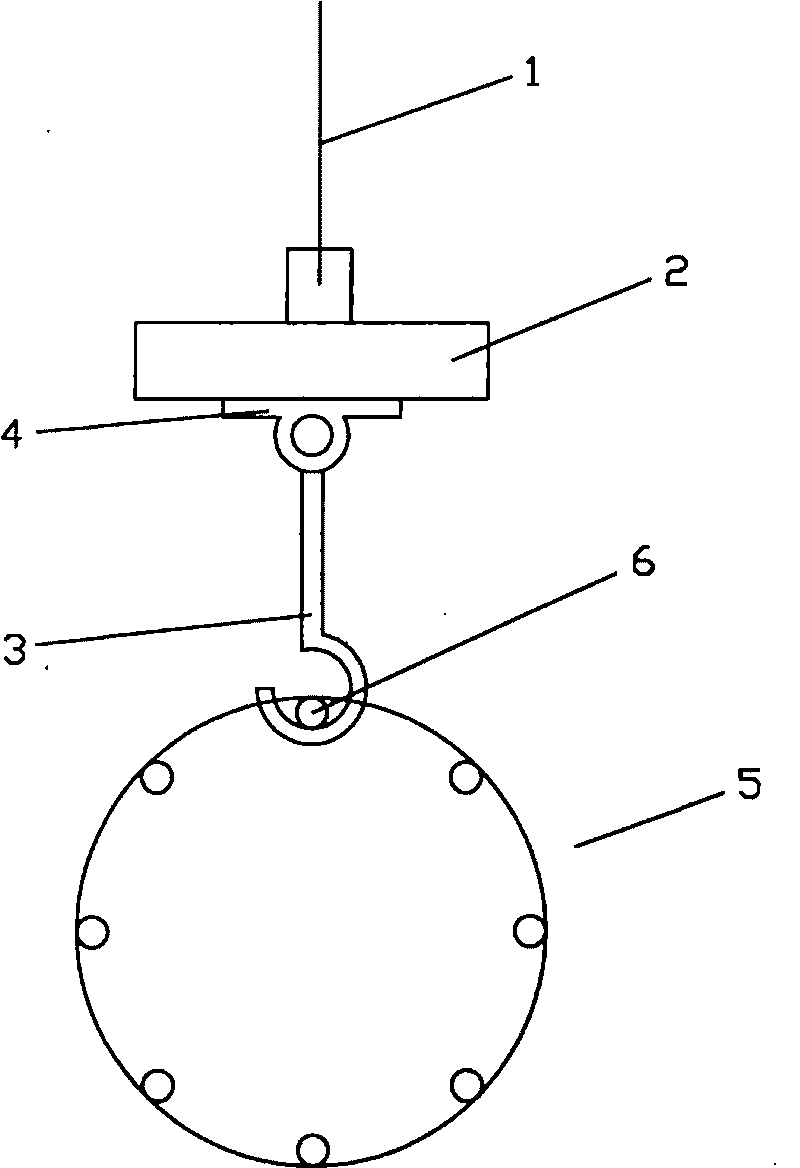

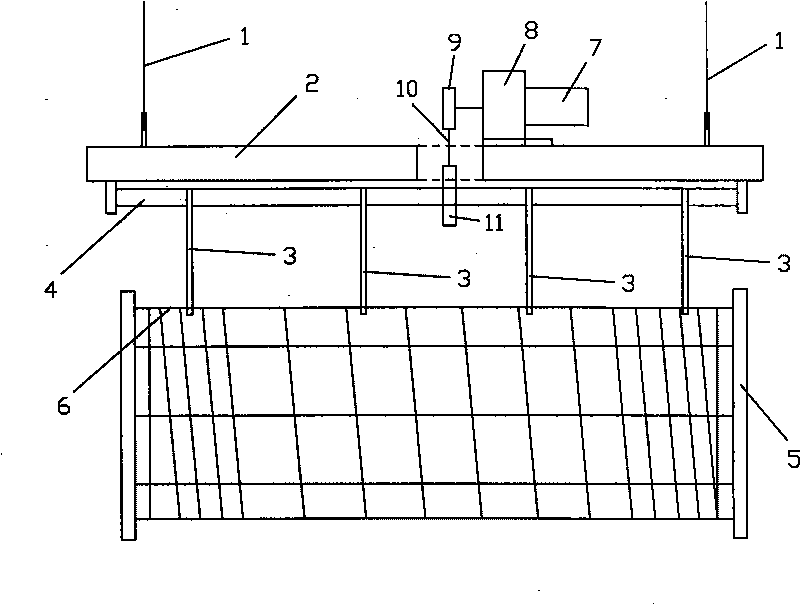

[0010] refer to figure 1 , figure 2 , a steel cage gripper for pipe piles of the present invention, comprising a bridge crane steel wire rope 1, a bracket 2 connected to the steel wire rope 1, a hook 3 arranged below the bracket 2, at least two hooks 3 are arranged below the bracket 2, Usually there are four hooks 3, so that the stress point of the steel cage 5 is more balanced, and the steel cage 5 is less likely to be deformed. A rotating mechanism 4 for driving the hook 3 to rotate is also provided between the hook 3 and the bracket 2.

[0011] The above technical solution can also have the following improvements: the distances between the hooks 3 are equal; the transmission mode of the rotating mechanism 4 is belt transmission or chain transmission or gear transmission or friction wheel transmission or hydraulic transmission or pneumatic transmission; The transmission mode of the rotating mechanism 4 is a chain drive, and the support 2 is provided with a motor 7, a speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com