Manufacturing method of titanium alloy ship bulbous bow inner hull

A technology of bulbous bow and titanium alloy, which is applied in the manufacture of bulbous bow inner shell of ships, titanium alloy

In the field of manufacturing the bulbous bow inner shell with materials, it can solve the problems of weak penetration, small radiation surface, and easy collision damage, etc., and achieve the effect of ensuring accuracy and balanced force points

Active Publication Date: 2014-06-11

HUDONG ZHONGHUA SHIPBUILDINGGROUP

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The radiation surface is small, the penetrating power is weak, easy to be damaged by collision, and the service life is short

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

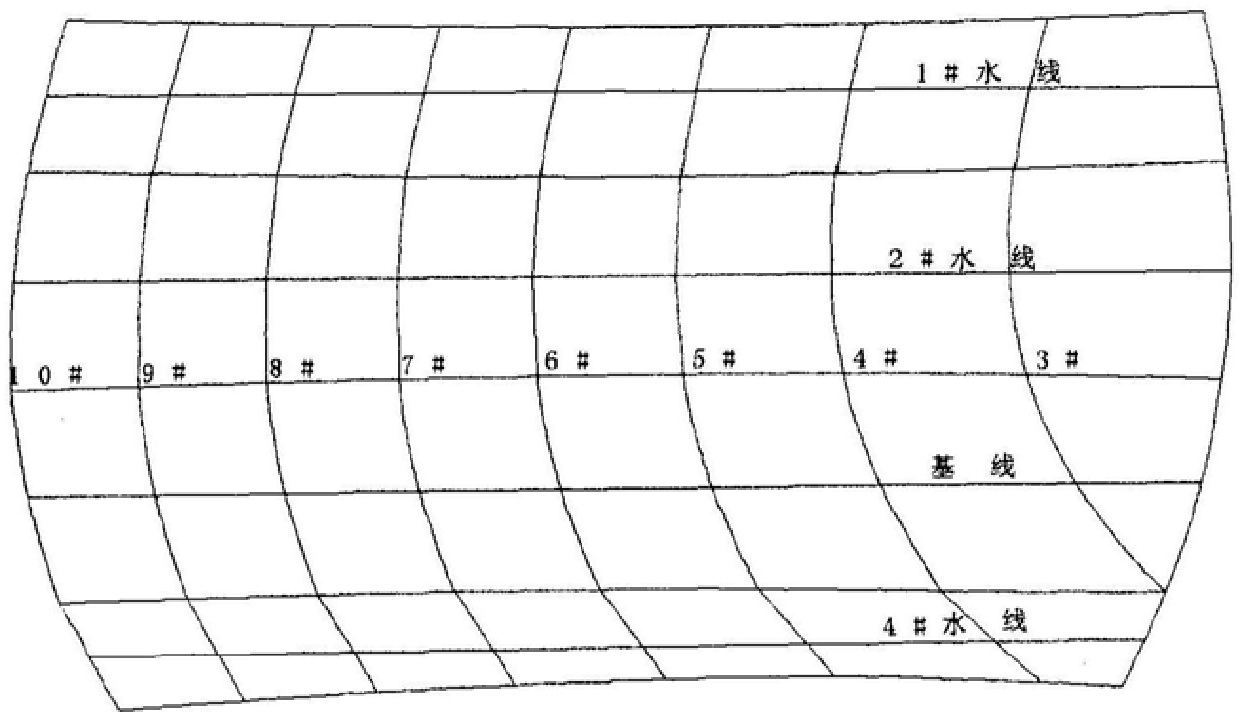

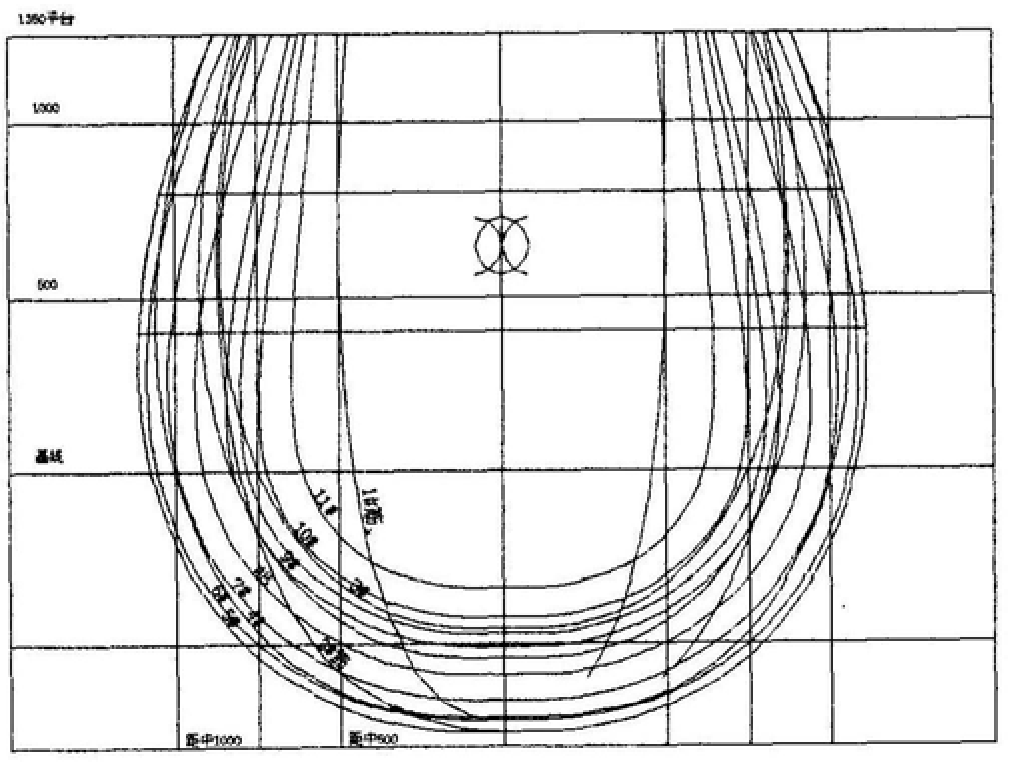

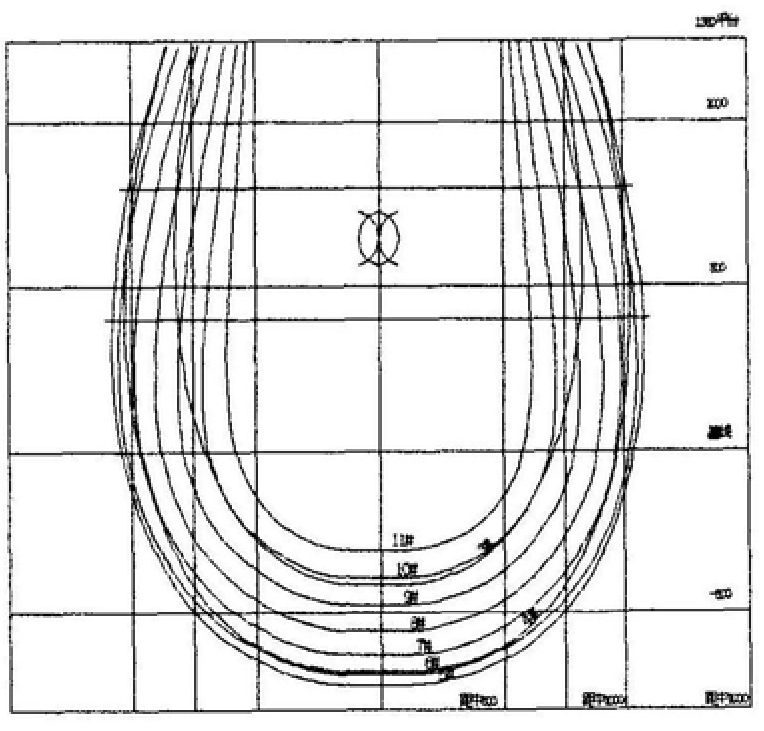

The invention discloses a manufacturing method for the bulbous bow inner hull of a titanium alloy ship, which comprises the following steps: positioning the inner hull linearly normal to the vertical outer shell; fixing the distance in the three-dimensional space of the tire frame of the inner shell; The method adopted in the present invention can ensure the accuracy of the inner shell molding line, balance the stress points where the inner and outer shells connect, and increase the strength of the shell. The linear normal direction of the inner shell is positioned vertically to the outer shell so that the distance between the inner and outer shells is basically consistent. The tire frame of the inner casing is fixed in three-dimensional space, which effectively controls the difference in curvature of the fan-shaped surface with different widths and heights, and improves the accuracy of coordinate values in different spaces. Implement the combined expansion of parts on the grid of the inner shell, so that the expansion momentum of the shell can be adjusted to be basically the same, and the encrypted waterline and the small straight section of the rib head can improve the sampling rate of the external dimensions of the parts and the curvature of the line shape. The tightness of the structural joints is also increased.

Description

Titanium alloy ship bulbous bow inner shell manufacturing method Technical field [0001] The present invention relates to shipbuilding, particularly to the manufacture of bulbous bow inner hulls of ships, specifically a titanium alloy The material is used as the manufacturing method of the bulbous bow inner shell. Background technique [0002] The bulbous bow of the ship can not only reduce the wave-making resistance, but also increase the speed of the ship. More importantly, the built-in sonar tracks the water Under the target, measure the azimuth, distance and speed, and monitor the multi-directional underwater information, and transmit the detected information to the underwater acoustic system, Provide monitoring reports of torpedoes attacking the ship, and provide accurate data to the command system to promptly destroy incoming torpedoes. What existing my country's warship bulbous bow manufacture mainly adopts is glass fiber reinforced plastics (3201SGRP) resin mater...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B63B9/06B63B3/46

Inventor 孙伟芳曹云勇席建共吴静芬徐卫谢戎方莹耿德品

Owner HUDONG ZHONGHUA SHIPBUILDINGGROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com