Mechanical puller for disassembling impellers and balance plates

A balance plate and impeller technology, which is applied to mechanical equipment, parts of pumping devices for elastic fluids, machines/engines, etc., can solve the problem of lack of effective disassembly tools for dismounting balance plates, balance discs and impellers, and achieve safety The coefficient is improved, it is not easy to slip, and the effect of stable pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

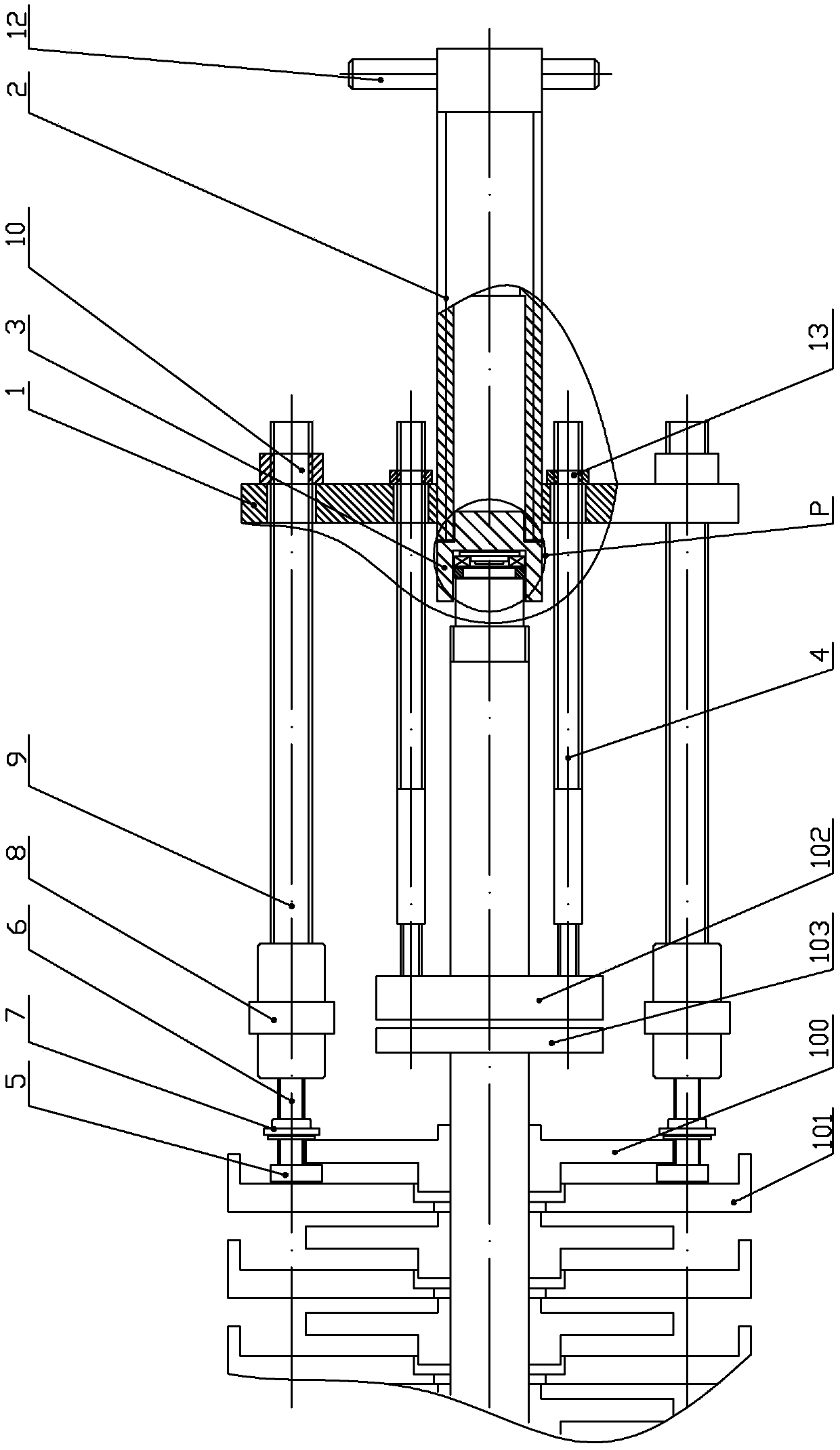

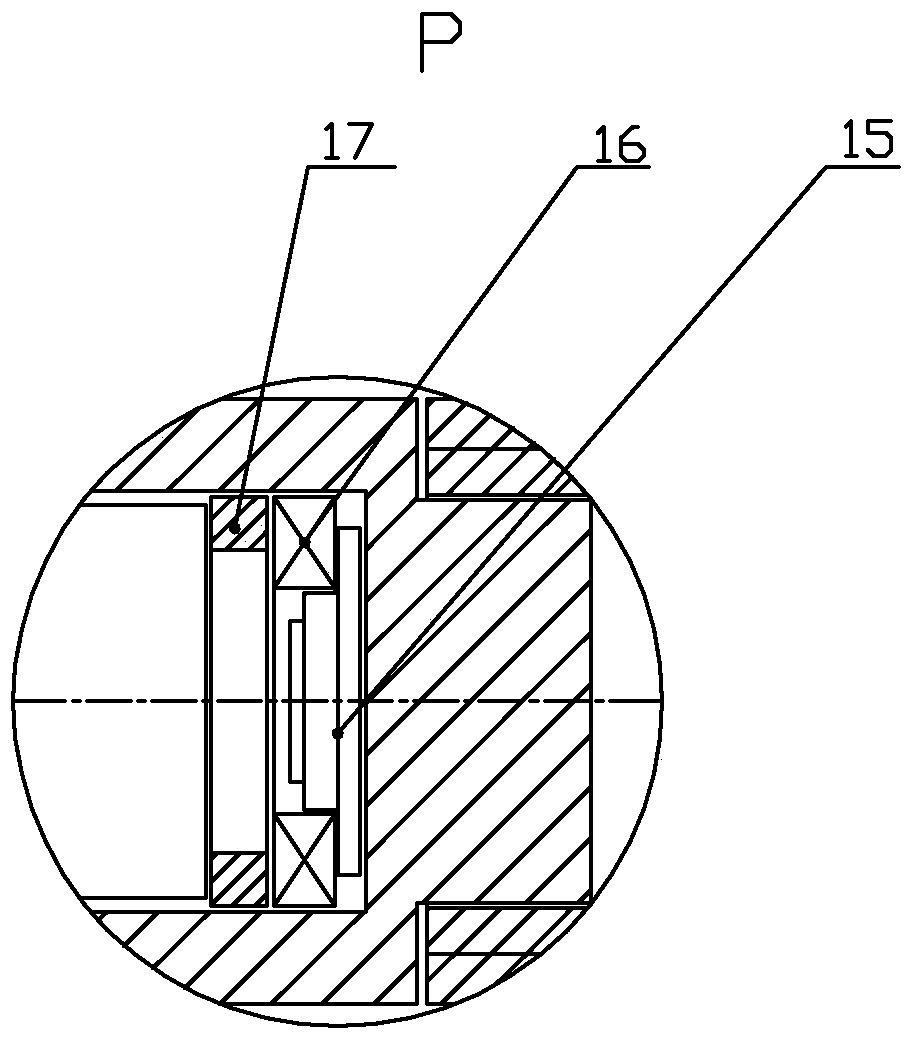

[0030] Specific implementation mode one: combine Figure 1 to Figure 14 , Figure 17 and Figure 18 Describe this embodiment, the mechanical puller used for removing the impeller and the balance plate in this embodiment includes a connection plate 1, a top screw 2, a top sleeve 3, two sets of impeller removal devices and two second screw screws 4,

[0031] Each set of impeller removal device includes pull plate 5, connecting bolt 6, first lock nut 7, connection nut 8, first lead screw 9 and second lock nut 10, and two sets of impeller removal devices are arranged symmetrically about the central axis of the impeller , the tie plate 5 is located between the first-stage impeller 100 and the first-stage pump section 101, the connecting bolt 6 is located at the outer circle of the first-stage impeller 100, one end of the connecting bolt 6 is screwed to the tie plate 5, and the tie plate 5 is connected to the first-stage impeller One end surface of 100 is in close contact with the...

specific Embodiment approach 2

[0038] Specific implementation mode two: combination figure 1 , Figure 8 and Figure 9 In describing this embodiment, the thickness of the pull plate 5 is less than 7 mm. This design ensures that the pull plate can be smoothly placed between the impeller and the pump section. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

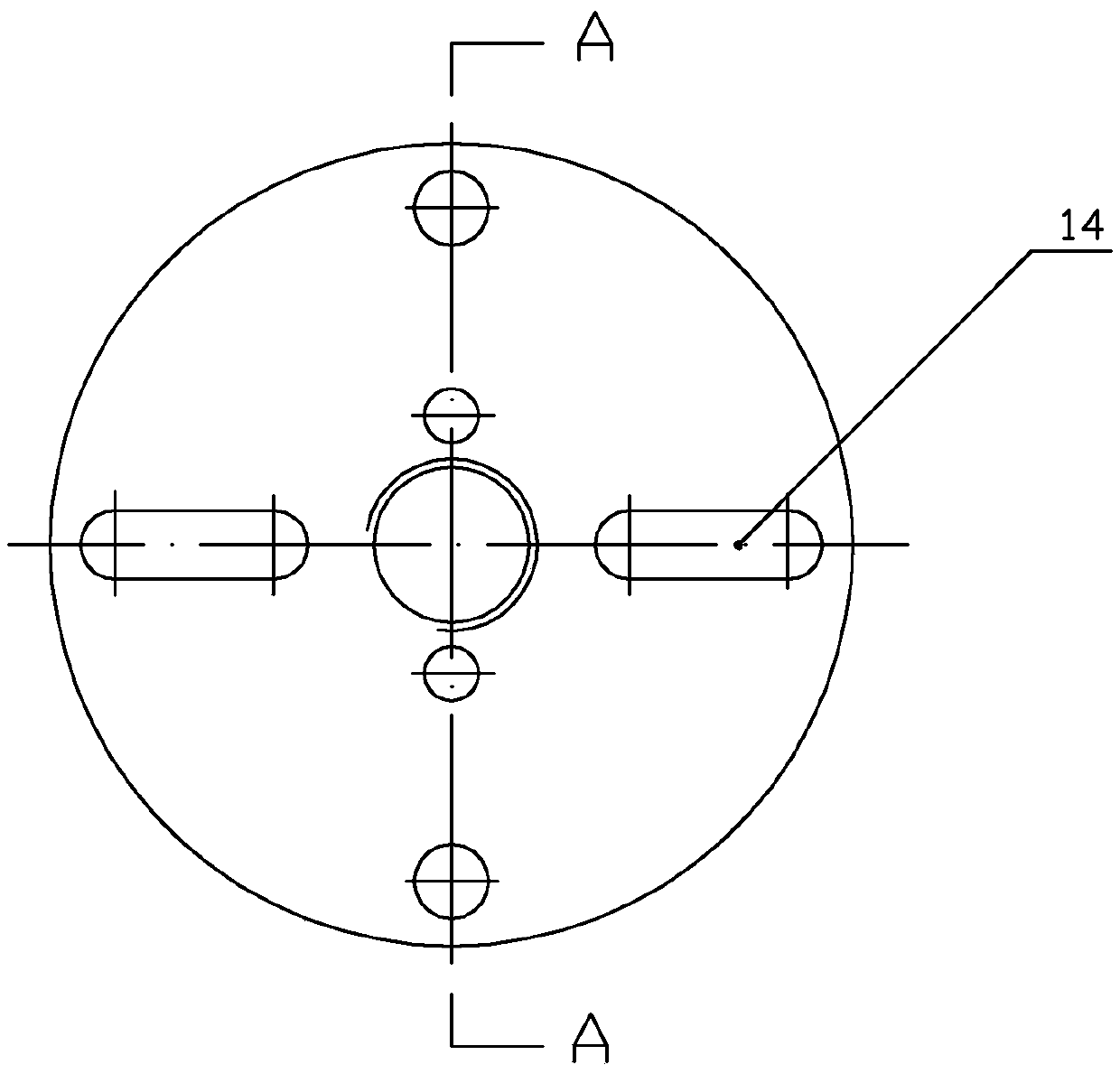

[0039] Specific implementation mode three: combination image 3 To illustrate this embodiment, the connecting plate 1 is also processed with two long holes 14 arranged symmetrically along its central axis. With this design, for parts that need to be disassembled on other shafts (such as bearings, bushings and gears of various specifications), the top sleeve that matches the diameter of the corresponding shaft end can be replaced, and the screw can be inserted into the long hole on the connecting plate. Arbitrary placement can be used to disassemble other parts on the shaft, which makes the disassembly puller more versatile and safer, and greatly improves the value of parts and disassembly efficiency. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com