Connected graphite crucible applied to producing vanadium-nitrogen alloy products

A vanadium-nitrogen alloy and graphite crucible technology, which is applied in the field of production tools for tunnel pusher kilns, can solve problems such as uneven stress points, improve heat conduction speed and heat conduction rate, reduce production process, and reduce the probability of oxidation reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

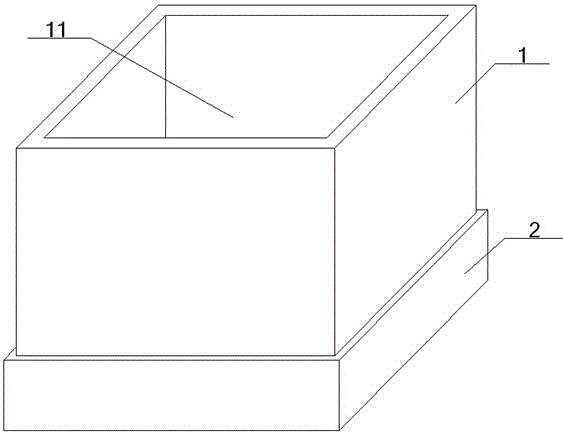

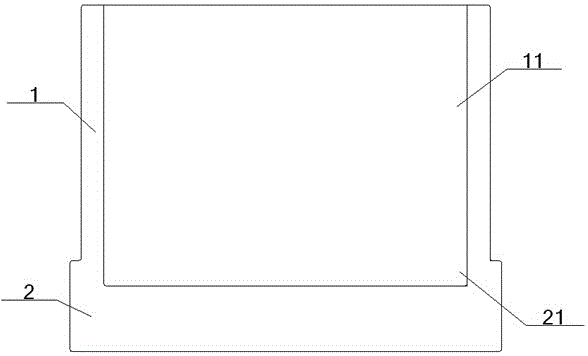

[0042] see figure 1 – figure 2 , a conjoined graphite crucible used in the production of vanadium-nitrogen alloy products, comprising a crucible 1 and a push plate 2, the crucible 1 and the push plate 2 are an integrated structure that is perpendicular to each other and coaxially connected, the bottom of the crucible 1 and the push plate The top of the plate 2 is connected; the inside of the crucible 1 is provided with a coaxial crucible cavity 11, and the inside of the push plate 2 is provided with a coaxial push plate cavity 21, and the top of the crucible cavity 11 is connected to the top of the crucible 1. flush, the bottom of the crucible cavity 11 communicates with the top of the push plate cavity 21, and the bottom of the push plate cavity 21 is located between the bottom of the crucible 1 and the bottom of the push plate 2;

[0043] The crucible 1, the crucible cavity 11, the push plate 2, and the push plate cavity 21 are all cuboids, the cross-sectional areas of the...

Embodiment 2

[0045] Basic content is the same as embodiment 1, the difference is:

[0046] The properties of the graphite are: the density is greater than 1.70g / cm 3 , powder particles with diameter less than 0.08mm, specific resistance ≤15Ω·mm 2 / m, anti-demolition strength ≥ 180KG / cm 2 , carbon content ≥ 99.99%, bulk density ≥ 1.75g / cm 2 , compressive strength ≥ 350KG / cm 2 , thermal expansion coefficient ≤1.6·10 -6 / °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com