Grinding device applied to glass surface machining

A technology of grinding device and glass surface, which is applied to grinding devices, grinding machine tools, grinding tools, etc., can solve the problems of no recycling and reuse of grinding liquid, low working efficiency of grinding devices, and increased glass processing costs, etc. The effect of good grinding effect, reducing maintenance costs and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

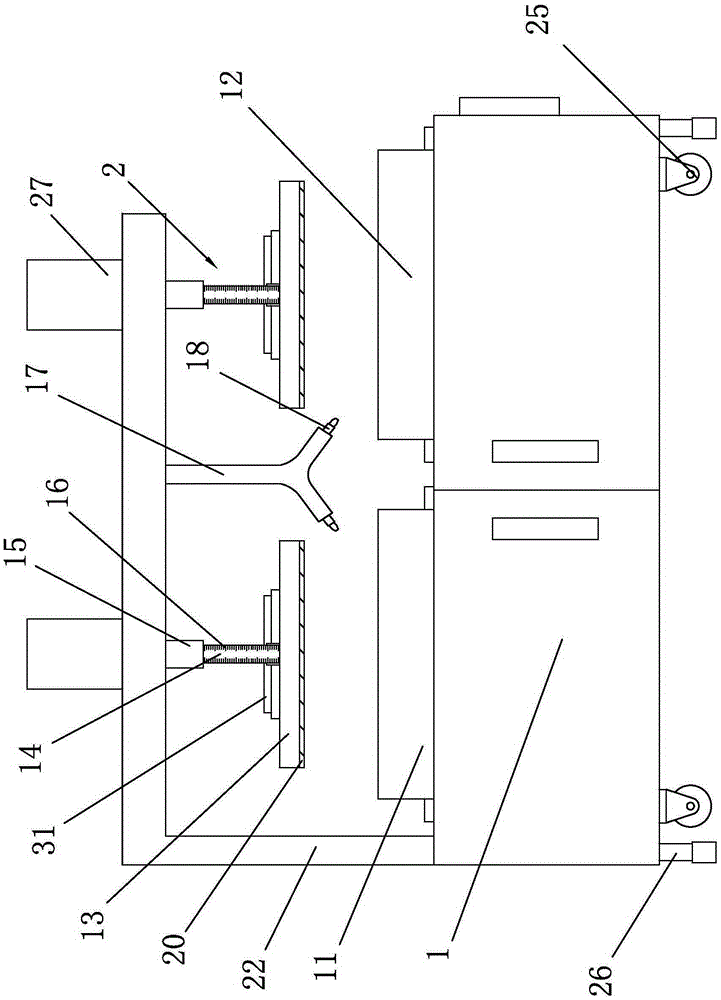

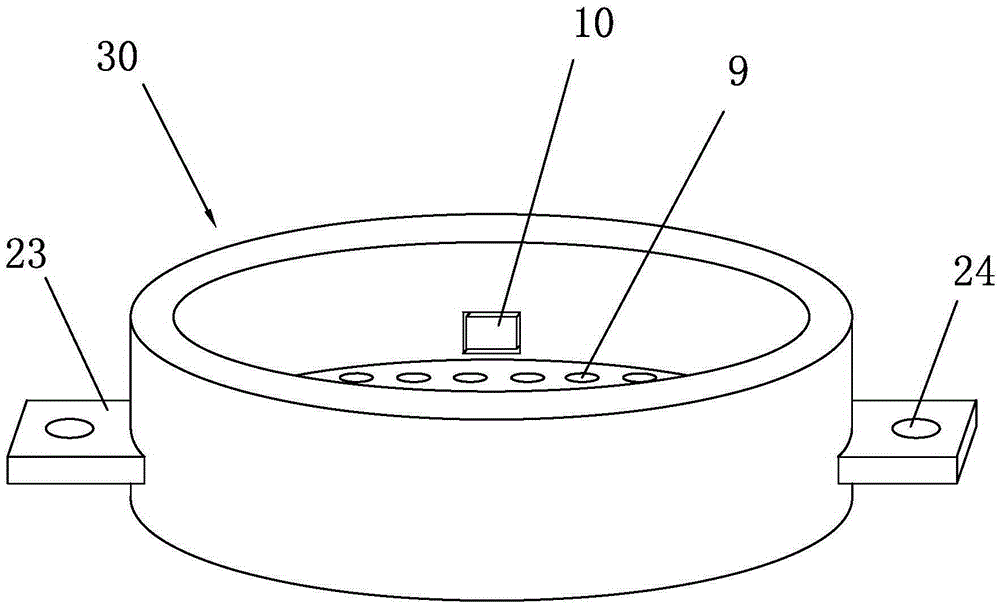

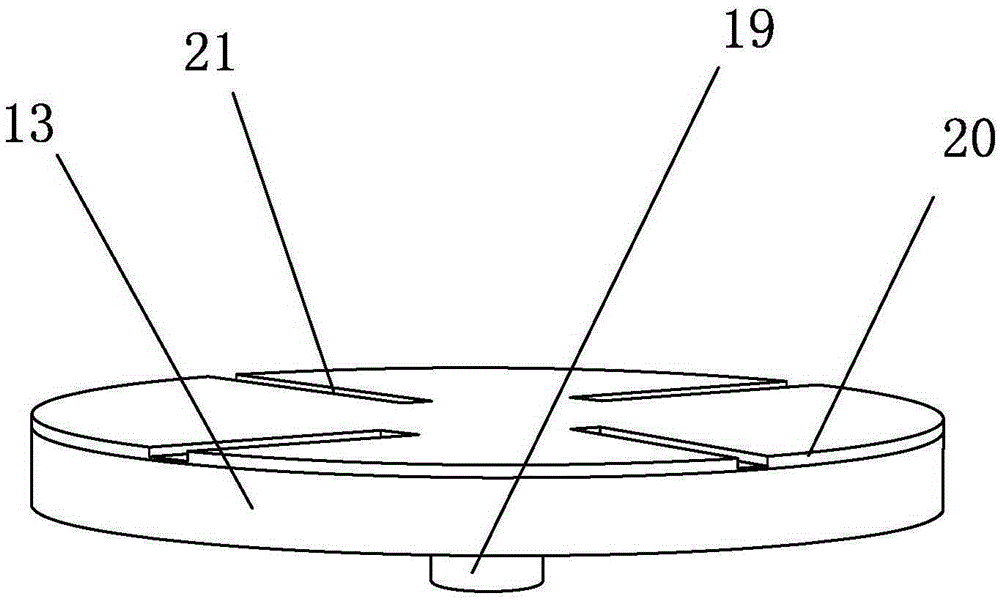

[0031] Such as Figure 1 to Figure 5 As shown, it is a grinding device applied to glass surface processing according to the present invention, which includes a working platform 1, a grinding frame 30, a grinding mechanism 2 and a grinding liquid mechanism. The bottom of the working platform 1 is provided with a moving roller 25 and a telescopic leg column 26. The quantity of moving roller 25 and telescopic leg column 26 is at least 4, by the design of mobile roller 25, can facilitate the handling and moving of grinding device, has expanded its scope of use, by the design of telescopic leg column 26, can facilitate grinding device Fixed to improve the stability of the grinding device. When the grinding device needs to be moved, the telescopic leg column 26 retracts so that the moving roller 25 can play a role. When the grinding device needs to be fixed, the telescopic leg column 26 is extended, and the whole design is more humanized , the rear end surface of the working platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com