High-reliability clutch mechanism

A technology of clutch mechanism and reliability, which is applied in the field of high reliability clutch mechanism, can solve the problems that the pawl cannot be pulled back in time, the work reliability, poor stability, and the driving force of the driving wheel cannot be transmitted, so as to achieve friction reduction, The effect of high working reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

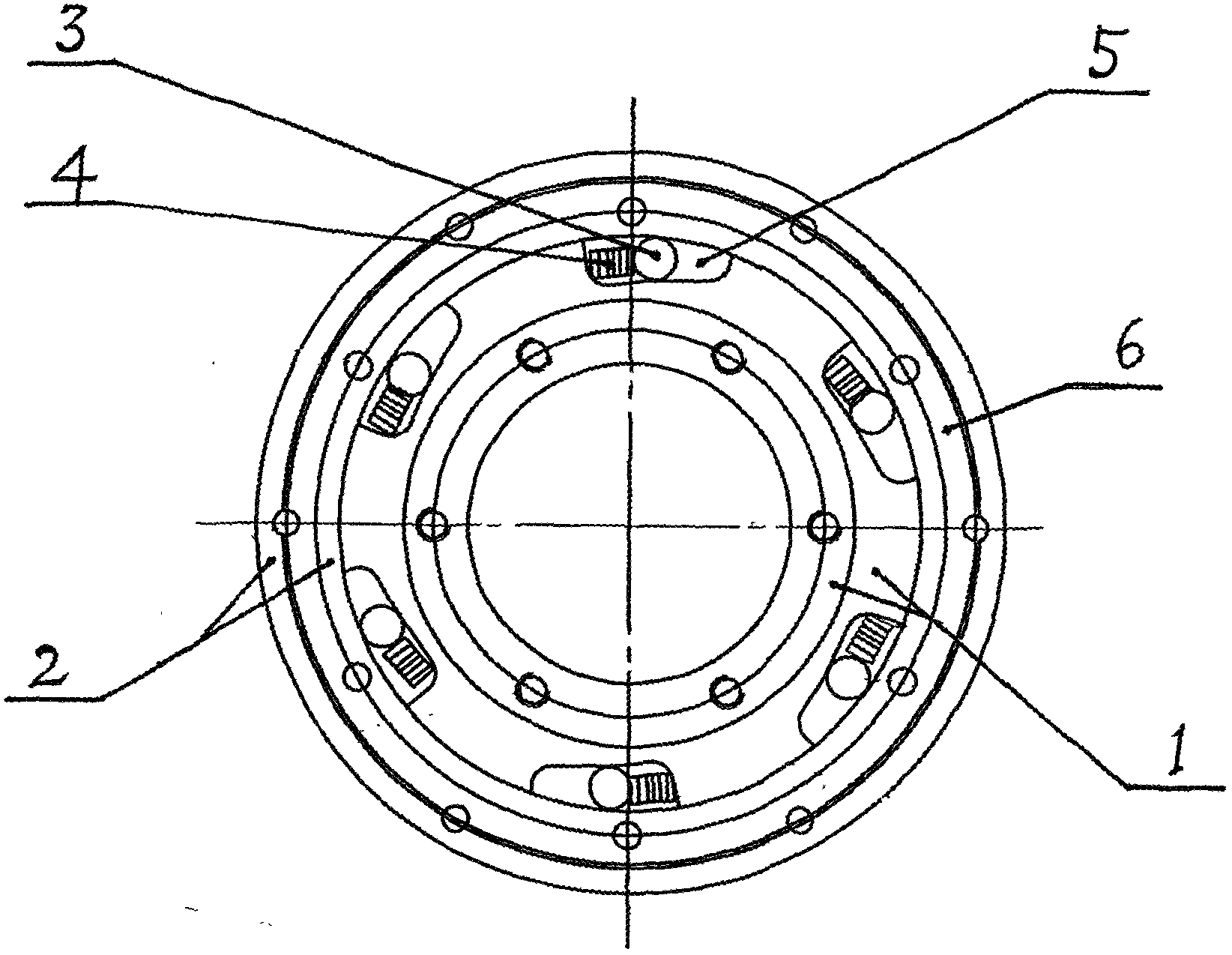

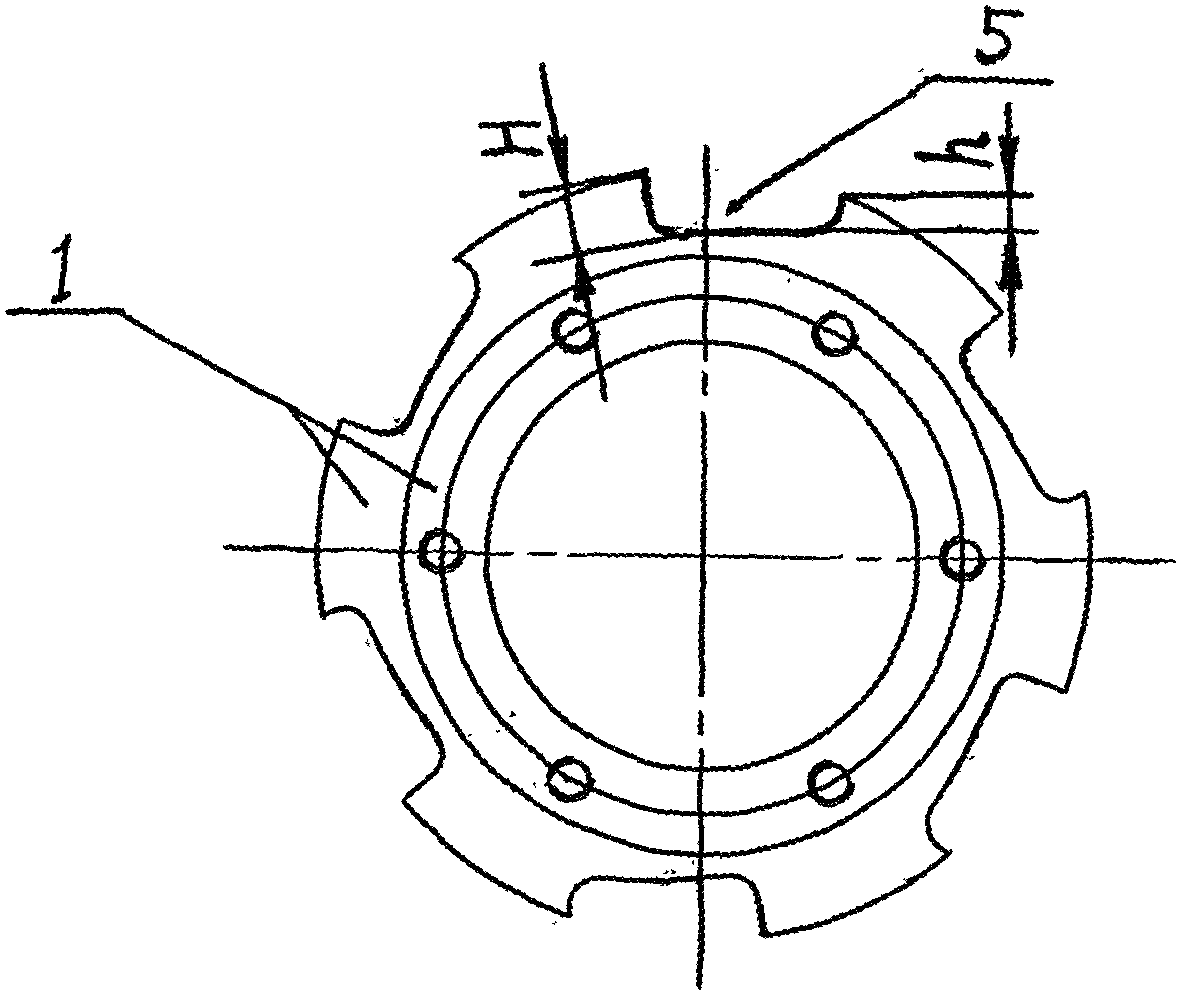

[0023] Example 1, in figure 1 In the schematic diagram shown in the structure, the present invention includes an inner shaft sleeve 1, an outer ring 2 arranged on its periphery, and 6 transmission parts that transmit the rotational force of the inner shaft sleeve 1 to the outer ring 2, and the inner shaft sleeve The outer edge of 1 is provided with 6 wedge-shaped grooves. The above-mentioned wedge-shaped grooves are special-shaped grooves that are deep at one end and shallow at the other end along the circumferential direction of the inner sleeve 1. figure 1 and figure 2In the schematic diagram shown, the wedge-shaped groove 5 is one of the above-mentioned six wedge-shaped grooves, the depth H of the front groove of each of the above-mentioned wedge-shaped grooves is greater than the depth h of the end groove, and is wedge-shaped, and the above-mentioned six wedge-shaped grooves are evenly arranged inside At the outer edge of the shaft sleeve 1, the above-mentioned 6 transmi...

Embodiment 2

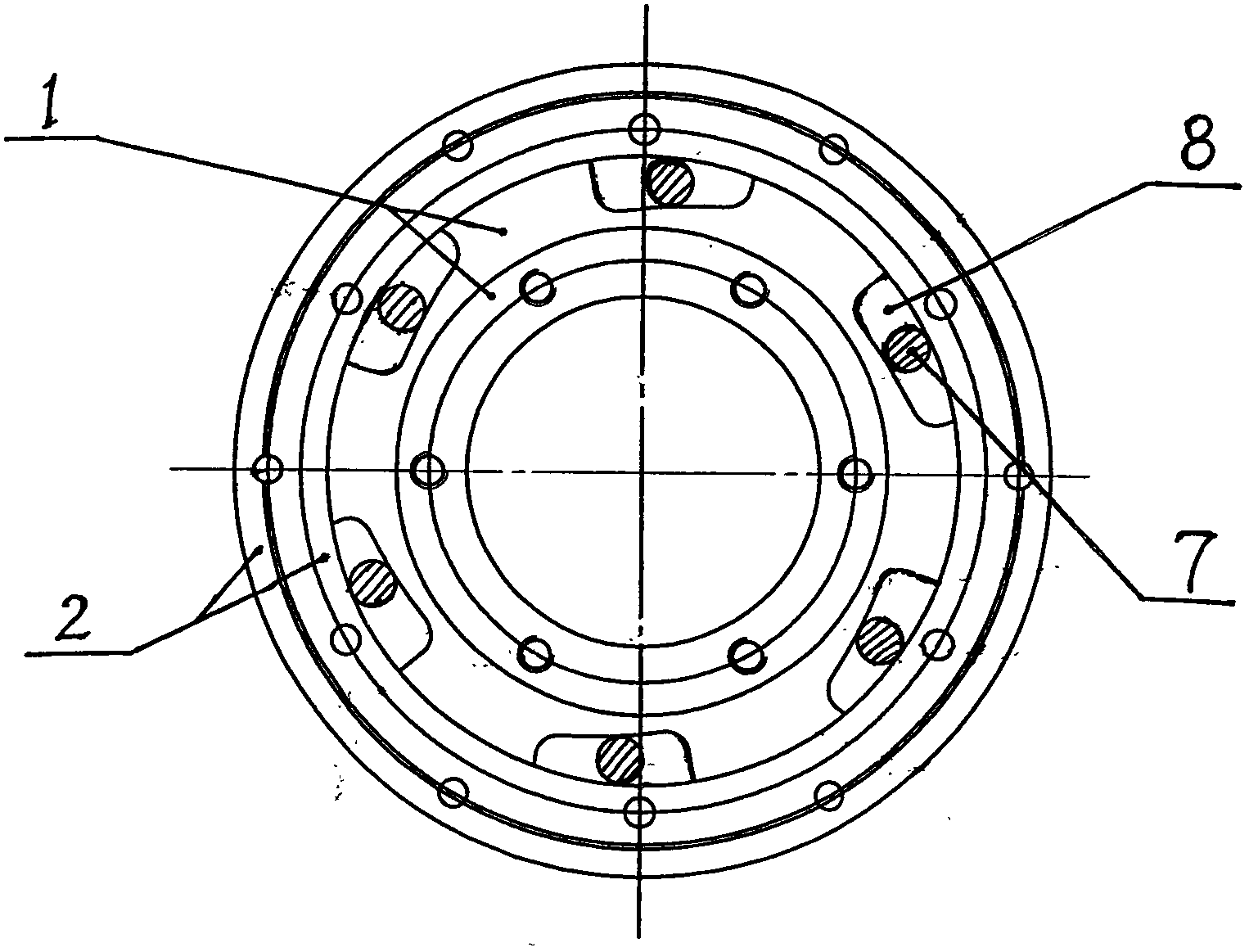

[0024] In Embodiment 2, the present invention has the same structure as that in Embodiment 1 except that the above-mentioned compression spring is omitted and the transmission part is a cylinder. exist image 3 In the schematic diagram shown in the structure, the present invention includes an inner shaft sleeve 1, an outer ring 2 arranged on its periphery, and 6 transmission parts that transmit the rotational force of the inner shaft sleeve 1 to the outer ring 2, and the inner shaft sleeve The outer edge of 1 is evenly provided with 6 wedge-shaped grooves, wedge-shaped groove 8 is one of them, and the above-mentioned 6 transmission parts are cylinders that can be arranged in the wedge-shaped grooves, and cylinder 7 is In one of them, the cylinder 7 is arranged in the wedge-shaped groove 8 , and its axis line is in the same direction as the axis line of the inner sleeve 1 , and the arrangement of each cylinder is the same as that of the cylinder 7 .

Embodiment 3

[0025] Embodiment 3, except that only one wedge-shaped groove and the corresponding ball are provided, other structures of the present invention are the same as those described in Embodiment 1. exist Figure 4 In the structural schematic diagram shown, the present invention includes an inner shaft sleeve 1, an outer ring 2 arranged on its periphery, and a transmission component that transmits the rotational force of the inner shaft sleeve 1 to the outer ring 2, that is, a round ball 3. A wedge-shaped groove is evenly arranged on the outer edge of the bushing 1, that is, a wedge-shaped groove 5. One end of the compression spring 4 is set on the inner wall of the deepest end of the wedge-shaped groove 5, and the other end is set on the ball 3 On, it forms a compressible top tight fit structure with the round ball 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com