Active positioning door rolling machine

A rolling door machine, active technology, applied in the direction of windows/doors, door/window protection devices, building components, etc., can solve the problems of large space occupation, inconvenient disassembly and assembly, complicated installation, etc., to achieve good rigidity, convenient installation, Sophisticated look

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

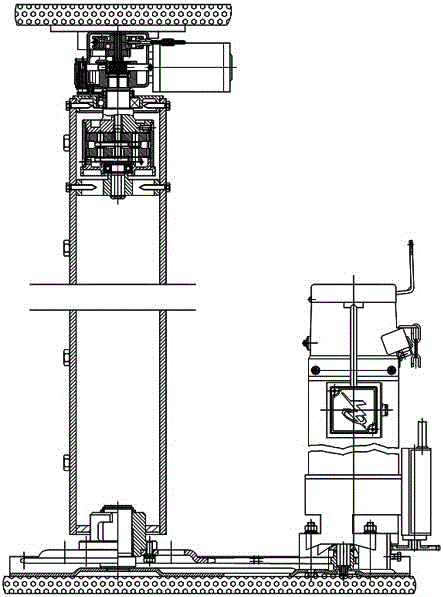

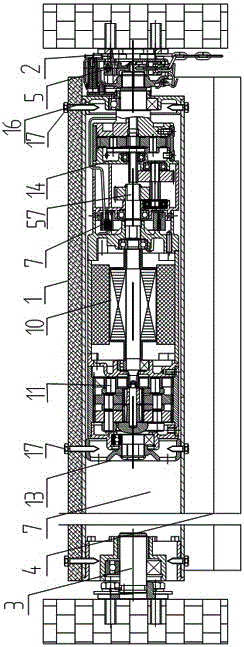

[0035] figure 1 , 2 , a kind of active positioning rolling door machine shown in 3, it comprises: reel assembly, main support 2 and attached support 3; Described reel assembly is provided with motor 10, electric gearbox 11, and fixedly winds a Roller blind 4; the output shaft of the motor 10 is connected to the driving wheel 13 through the electric gearbox 11, the driving wheel 13 is rotatably fixed on the attached support 3, and the reel assembly is fixedly sleeved on the driving wheel 13 , so that one end of the reel assembly can be rotatably fixed on the attached support 3; the other end of the motor 10 is connected to a ratchet 15 through a manual gearbox 14, and the ratchet 15 is rotatably fixed on the main support 2, so that the reel The other end of the assembly is rotatably fixed on the main support 2 through a ratchet 15; the reel assembly or the main support 2 is provided with a normally closed clutch mechanism 5 of the ratchet 15, so that when the normally closed ...

Embodiment 2

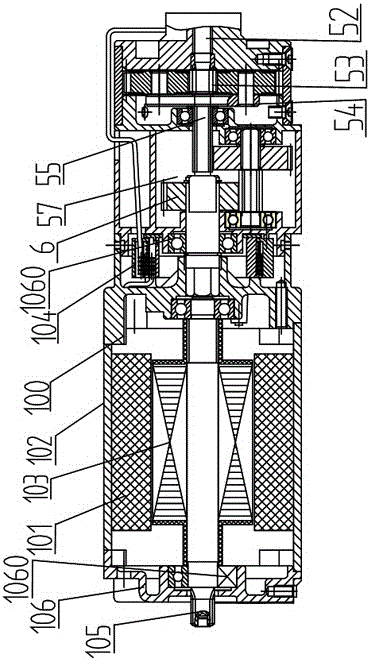

[0045] Such as Figure 5 An active positioning rolling door machine is shown, which includes: a reel assembly, a main support and an attached support; the reel assembly is provided with a motor 20, an electric gearbox 21, and a roller blind is fixedly wound; The output shaft of the motor 20 is connected to the driving wheel 22 through the electric gearbox 21, the driving wheel 22 is rotatably fixed on the attached support, and the reel is fixedly sleeved on the driving wheel 22, so that one end of the reel assembly can rotate fixed on the attached support; the other end of the motor 20 is connected to a rocker output end 24 through a manual gearbox 23, and the rocker 25 is fixed on the main support; on the reel assembly or the main support There is a normally closed clutch mechanism of the manual gearbox 23, so that when the normally closed clutch mechanism is in the open state, the output end of the manual gearbox 23 can rotate relative to the main support; when the normally ...

Embodiment 3

[0048] As described in Embodiments 1 and 2, mechanisms such as an active positioning rolling door machine and an emergency gearbox can also be located at the other end of the motor, and the specific scheme is as follows:

[0049] A motor and a driving wheel are arranged in the reel assembly, and the power output end of the motor drives and connects a common gearbox, and the driving wheel drives and connects the reel assembly; the driving wheel is provided with a normally open clutch, and through the normally open clutch Connect the output end of the common gearbox and the output end of the emergency gearbox respectively. When the normally open clutch is in the open state, the driving wheel and the output end of the common gearbox rotate synchronously and can rotate relative to the output end of the emergency gearbox. When the open clutch is in the closed state, the drive wheel can rotate relative to the output end of the common gearbox and rotate synchronously with the output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com