Mounting structure of scaling knife of fish killing machine

A technology of installation structure and installation mechanism, which is applied in the direction of fish cleaning / descaling, etc., can solve the problems of uneven force, breakage, and easy wear of the return spring, achieve uniform force points, increase service life, and improve structural stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

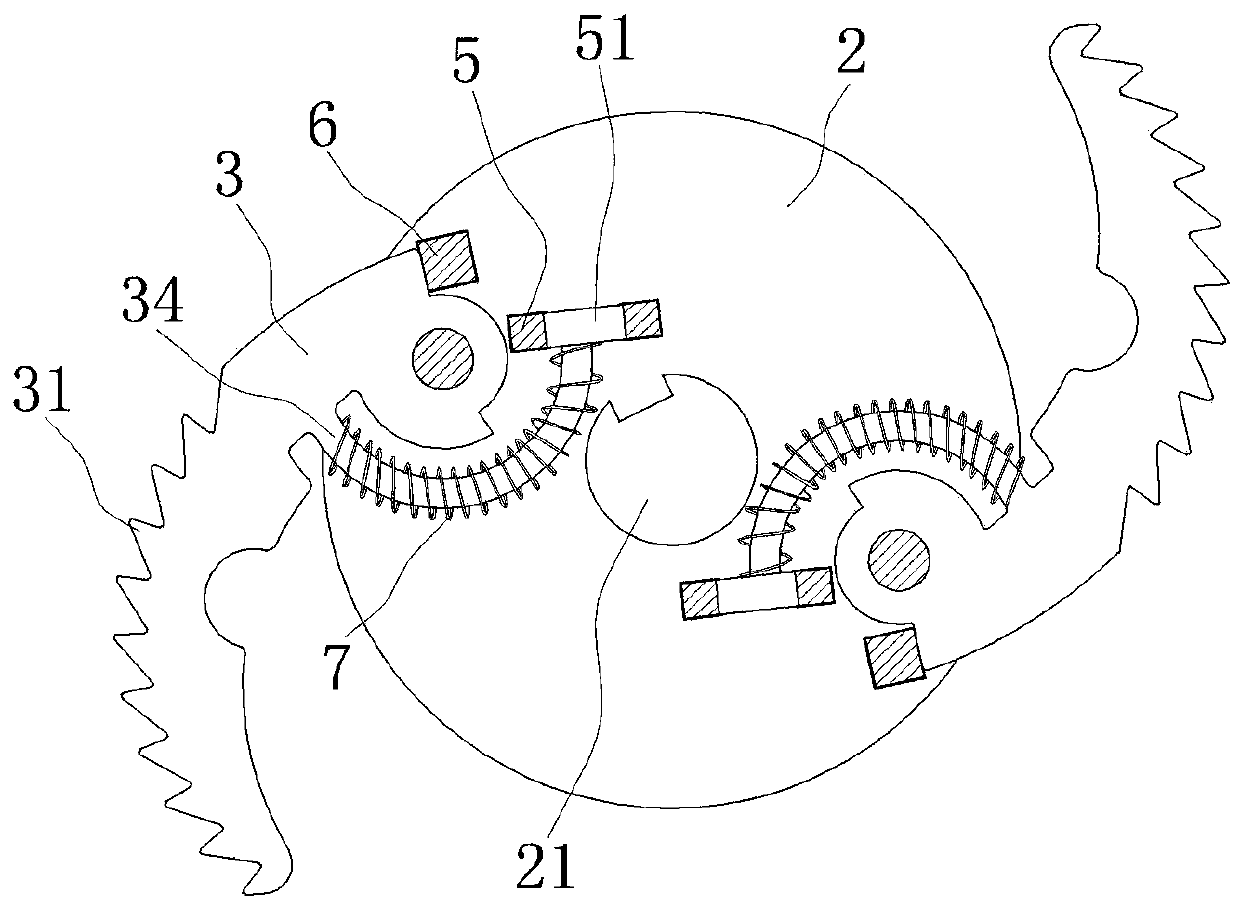

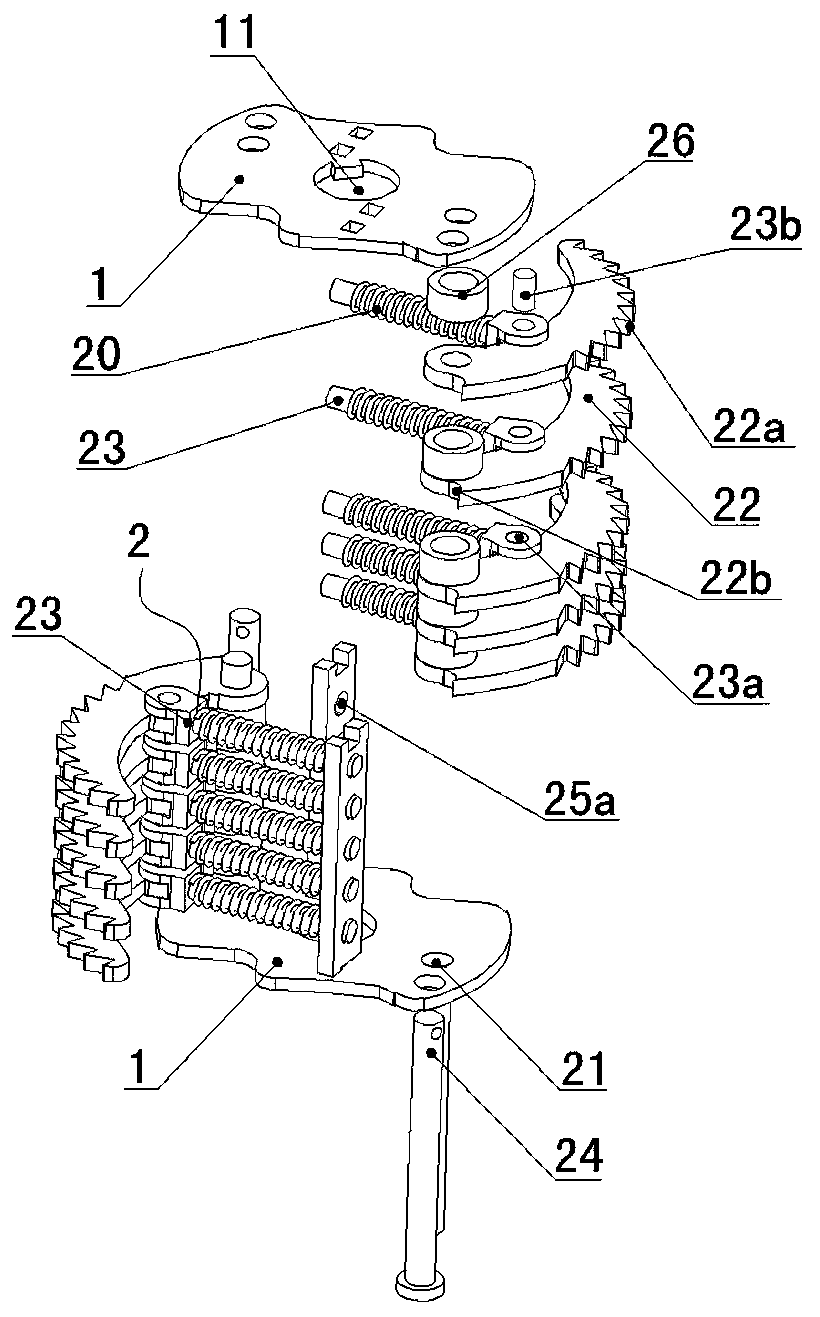

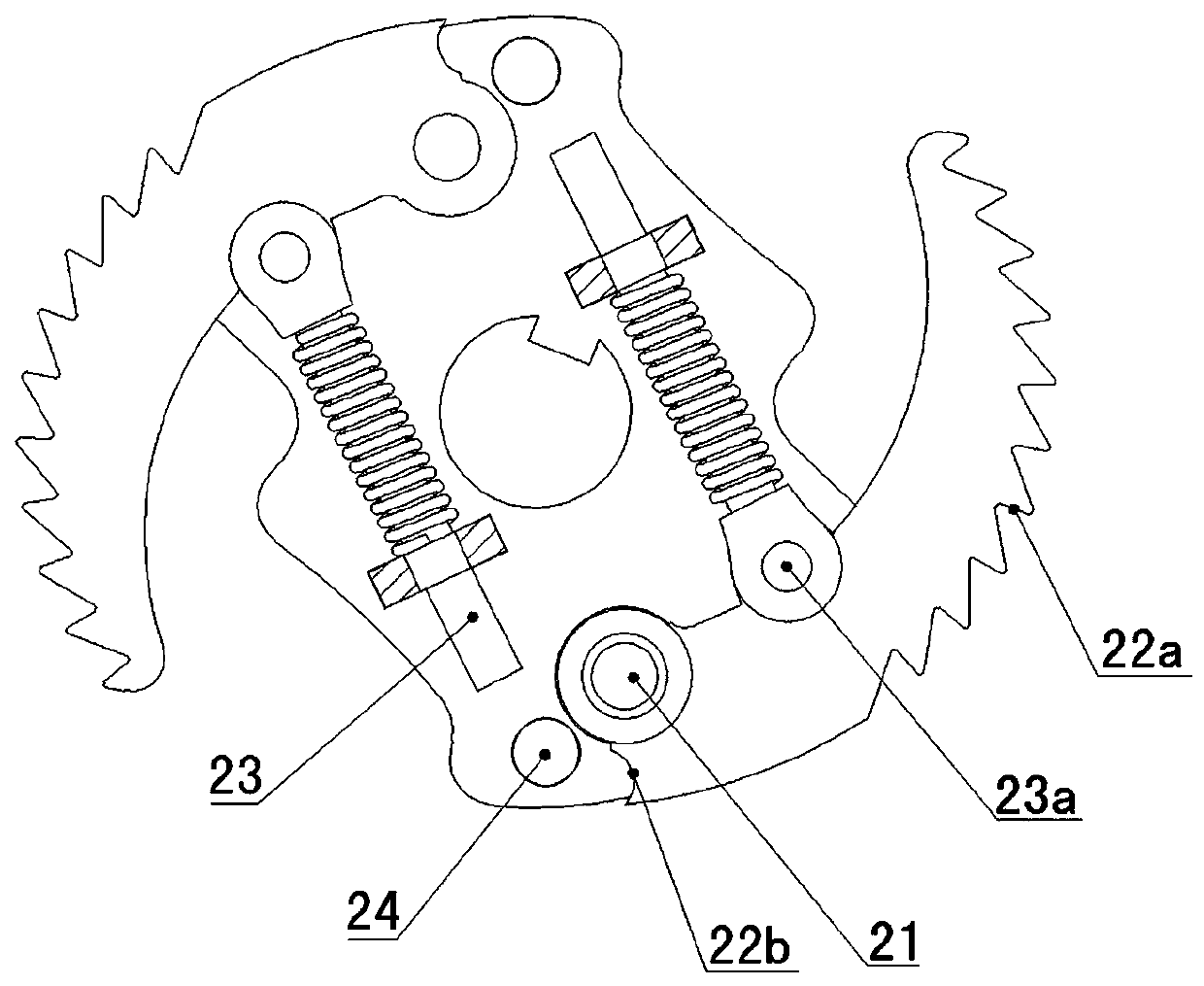

[0022] Such as figure 2 As shown in ~ 4, the installation mechanism of the fish scale knife of the fish killing machine includes two left and right fixed plates 1 that are arranged oppositely. There is at least one descaling combination 2 distributed on the axial peripheral side, and each descaling combination 2 includes a return spring 20 and a fixed rotating shaft 21 connected between two fixed disks 1 and extending in the axial direction. The rotating shaft 21 is provided with five descaling blades 22; the descaling blades 22 are a scimitar-shaped structure, and its outer side is provided with descaling serrations 22a from the tip to the tail, and a limit bayonet 22b is provided on the outside of the tail.

[0023] Each descaling combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com