Single-line reinforcement thermal insulation bearing shear wall with T-shaped hidden posts at end parts and manufacturing method of shear wall

A shear wall and hidden column technology, applied in the seismic field of building structures, can solve problems such as poor thermal insulation performance, poor seismic capacity, poor integrity, etc., and achieve the effects of reducing labor and materials, shortening construction period, and improving lateral resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

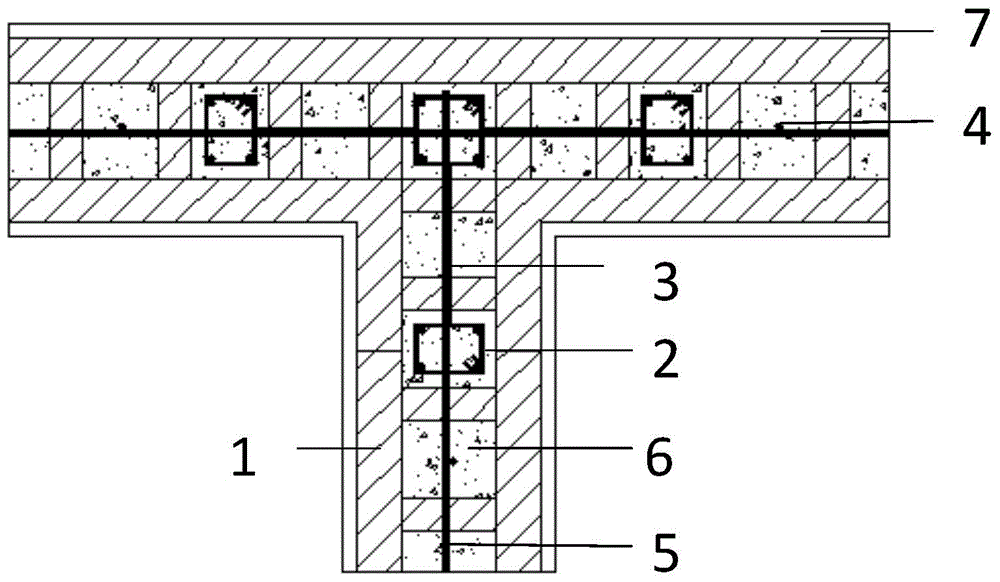

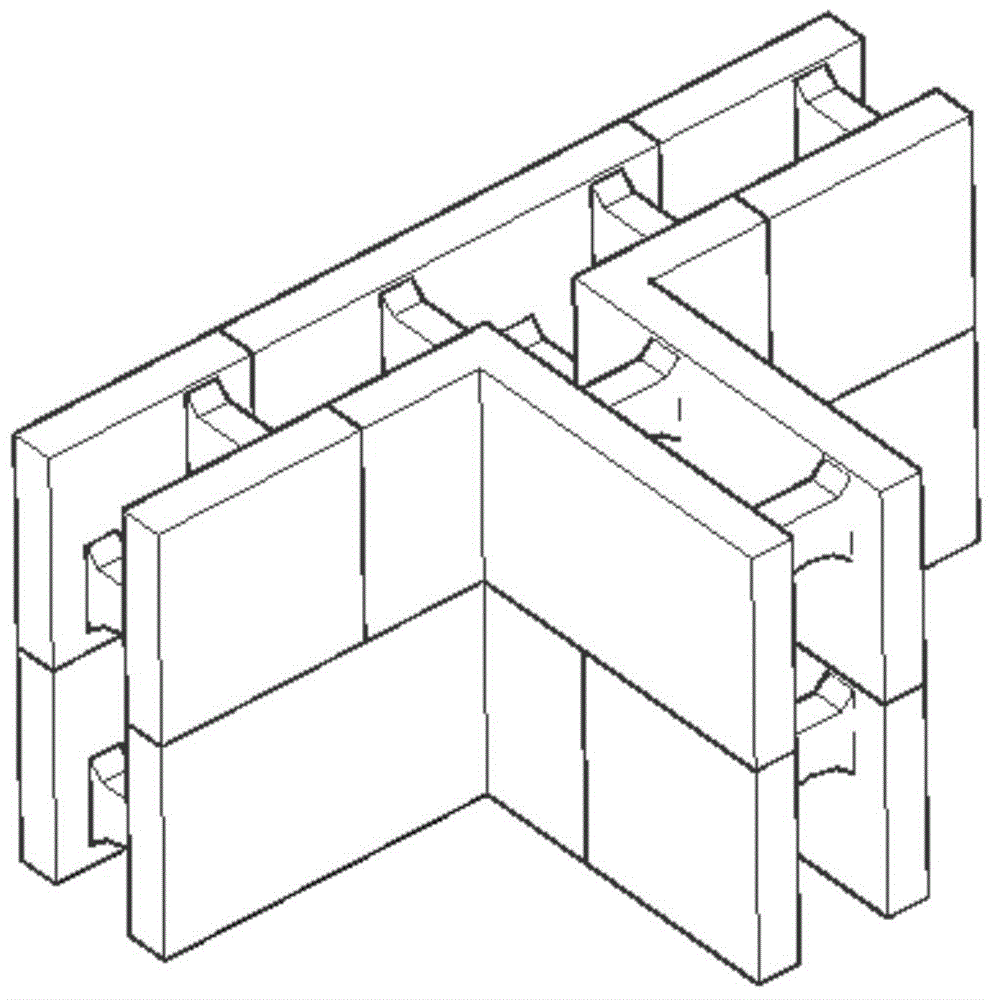

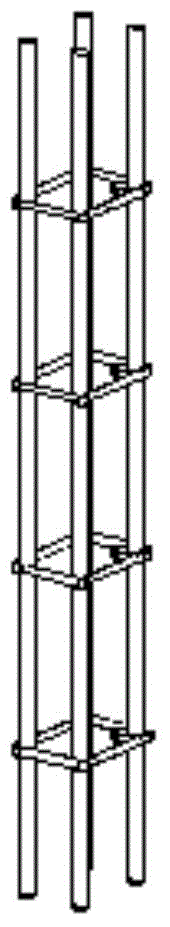

[0035] Such as Figure 1 to Figure 5The single-row thermal insulation and load-bearing shear wall with T-shaped hidden columns at the end shown is mainly composed of thermal insulation formwork 1, hidden columns 2, lattice-type steel mesh 3, vertically distributed steel bars 4, and horizontally distributed walls Steel bar 5, concrete 6, and fiber anti-cracking mortar surface layer 7; it is characterized in that: the end of the wall is equipped with special-shaped dark columns with steel bar trusses, and the middle part is a single-row reinforced wall; the special-shaped dark columns at the end The column is a T-shaped hidden column, which includes four hidden columns 2 and three latticed steel mesh 3, and the hidden columns 2 are located at the end and middle of the T shape of the hidden column, and the latticed reinforced mesh 3 is located between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com