Steel plate shear wall structure and construction method

A steel plate shear wall and steel web technology, applied in the direction of walls, building components, building structures, etc., can solve the problems such as the construction speed and quality are greatly affected by the weather, the concrete curing period is long, the formwork removal construction volume is large, etc. Achieve the effect of avoiding construction quality problems, excellent sound insulation and sound absorption performance, and improving lateral resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content of the present invention, the present invention will be described in detail with reference to the accompanying drawings and embodiments, but the embodiments of the present invention are not limited thereto.

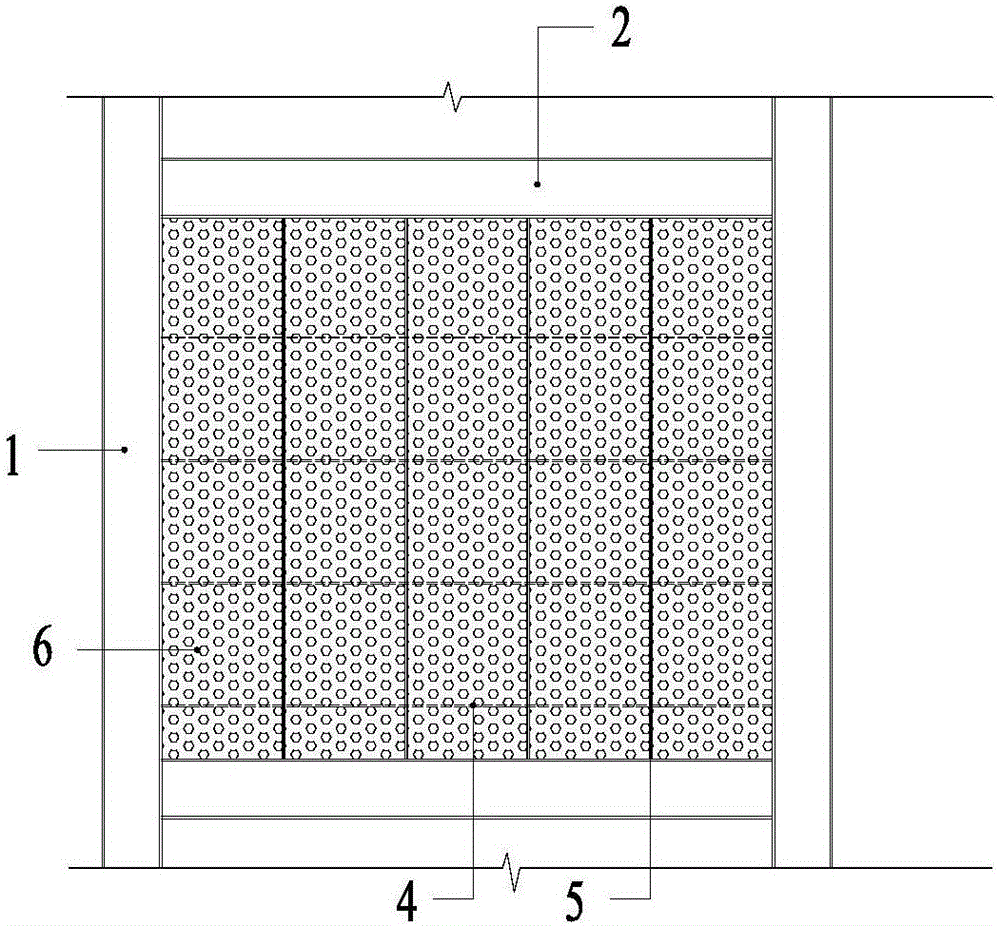

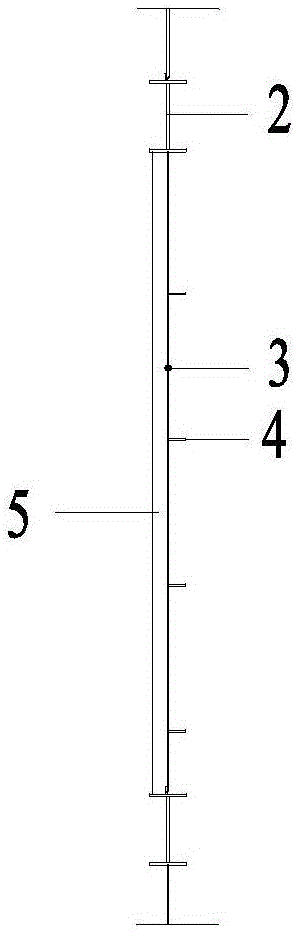

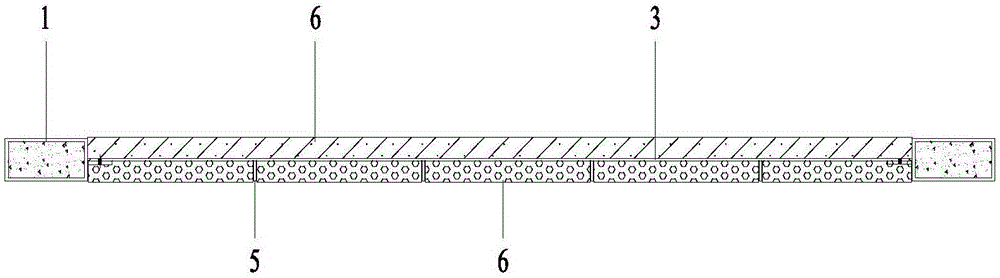

[0026] refer to Figure 1 ~ Figure 3 As shown, a steel plate shear wall structure in this embodiment includes a steel frame column 1, a steel frame beam 2, a steel web 3 and a lightweight wall panel 6, and the steel frame column 1 is a box-shaped steel tube concrete column, and the bottom passes The foot bolts are connected to the foundation, the steel frame beam 2 is an H-shaped steel beam with a cross-sectional size of 300×150×10×12, and both ends of the steel frame beam 2 are welded to the steel frame column 1 . In the rectangular space surrounded by two steel-framed columns 1 and two steel-framed beams 2, a steel web 3 is set, the upper and lower sides of the steel web 3 are welded to the steel-framed beam 2, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com