Light block wall with Z-shaped column frames and built-in single-row reinforcing bars and manufacturing method thereof

A wall and frame technology, applied to walls, building components, and earthquake resistance, can solve problems such as poor earthquake resistance, poor thermal insulation performance, and poor integrity, and achieve improved earthquake resistance, good shear resistance, and avoid column flute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

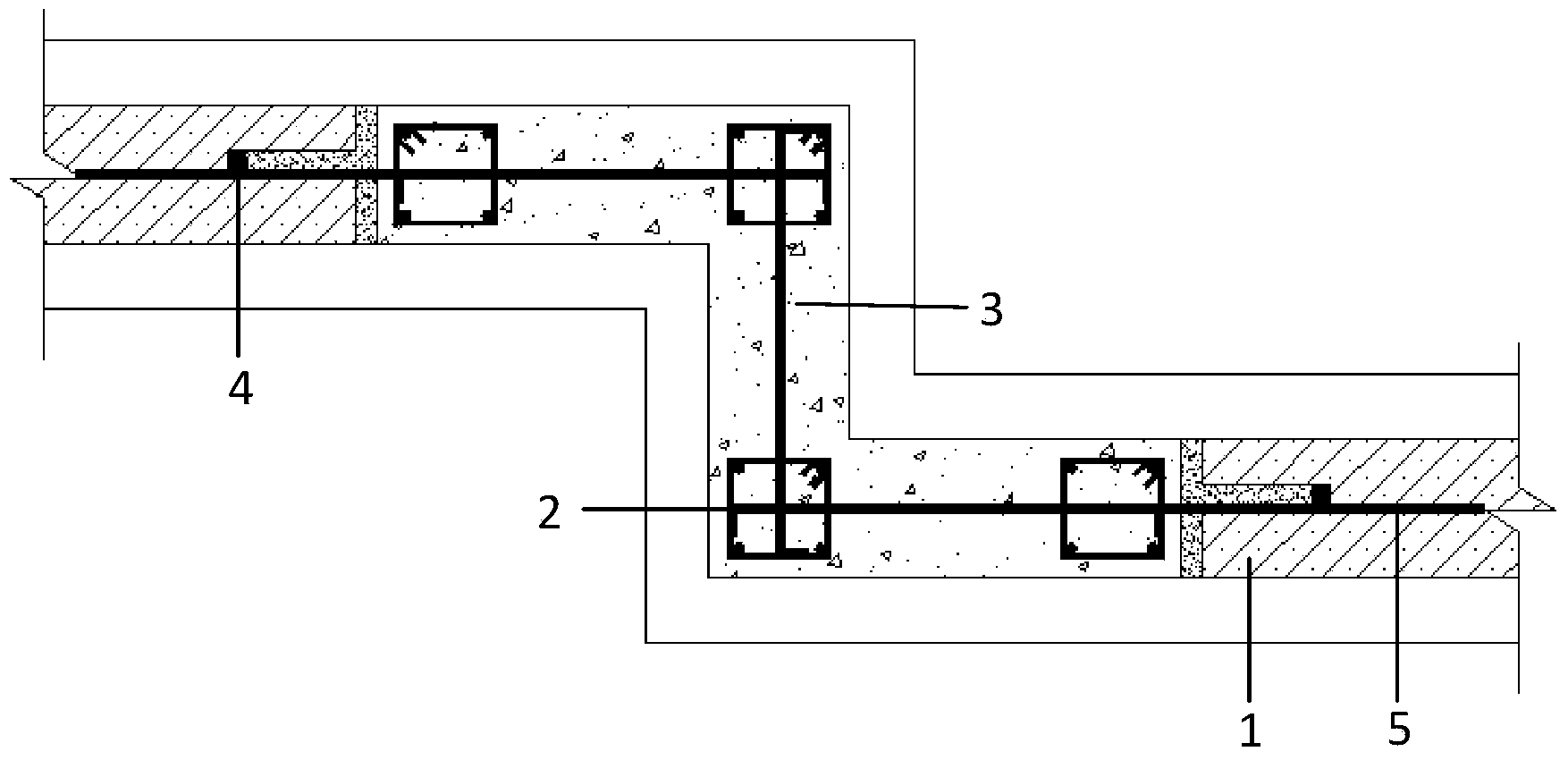

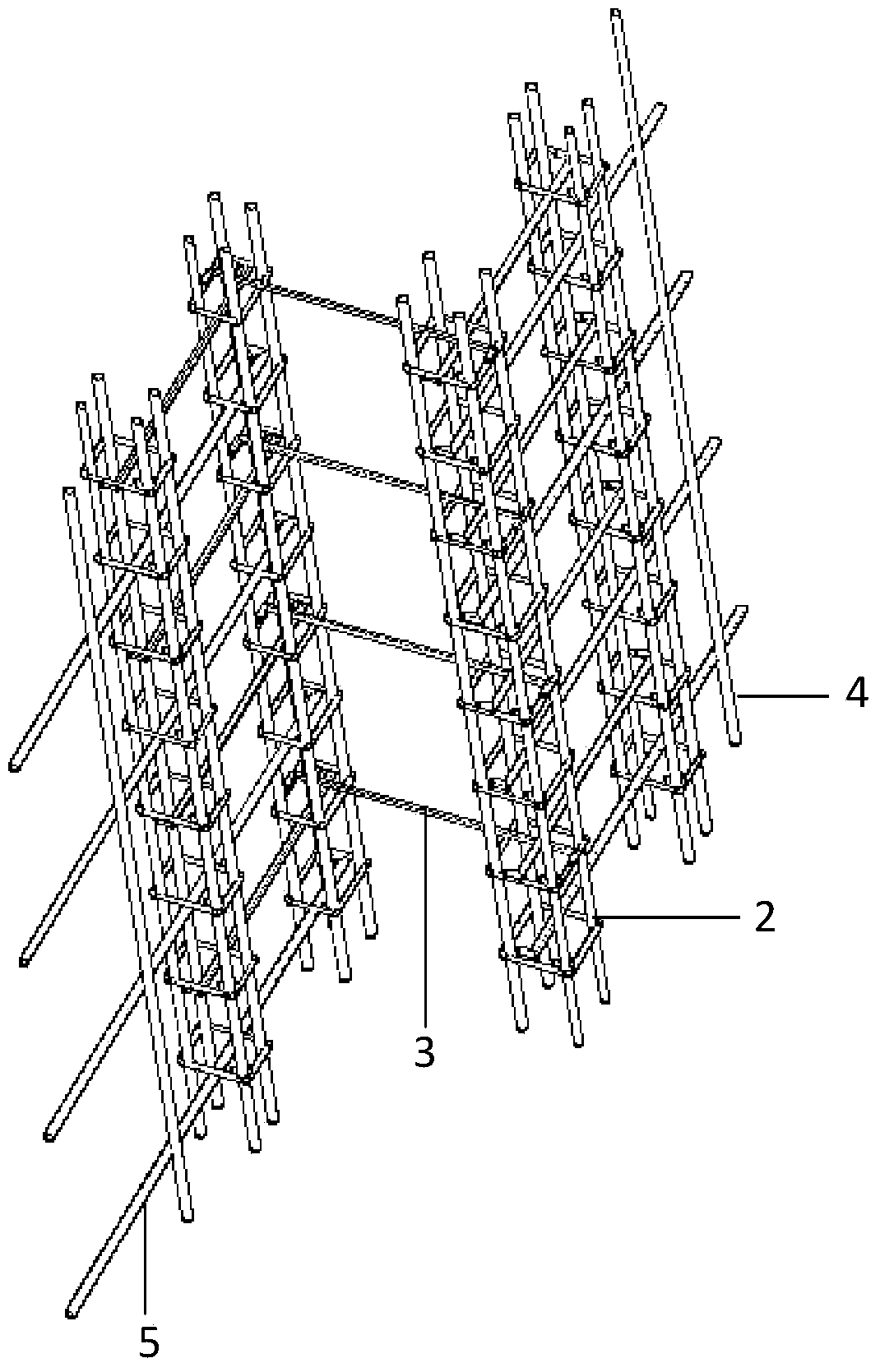

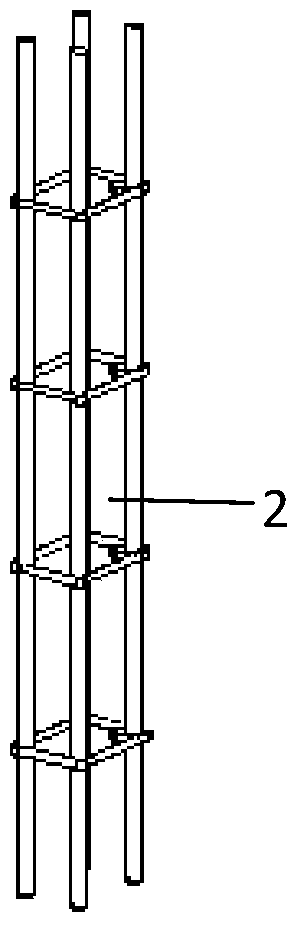

[0027] Such as Figure 1 to Figure 3 The shown Z-shaped column frame contains a single row of reinforced lightweight block walls, which are mainly composed of lightweight blocks 1, concealed columns 2, tie bars 3, vertically distributed steel bars 4, and horizontally distributed steel bars 5 combined; it is characterized in that: the end of the wall is provided with special-shaped frame columns with tie bars, and the middle part is a single row of reinforced walls; four hidden columns 2 and tie bars 3 form a Z-shaped column frame, so The concealed column 2 described above is located at the end and the middle of the Z-shaped column frame, and the tie bars 3 are located between two adjacent concealed columns; the concealed column 2 adopts four longitudinal steel bars and rectangular stirrups; the tie bars 3 are used to bind the reinforcing bars In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com