Double-ring combined super high-rise structure based on vertical face arc-shaped steel frame-support and forming method

A technology of steel support and arc-shaped steel, which is applied in the field of double-ring combined super high-rise structure and composition, can solve the problems of complex component composition and node connection structure, and achieve the effect of beautiful shape, guaranteed load-bearing performance and high lateral resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

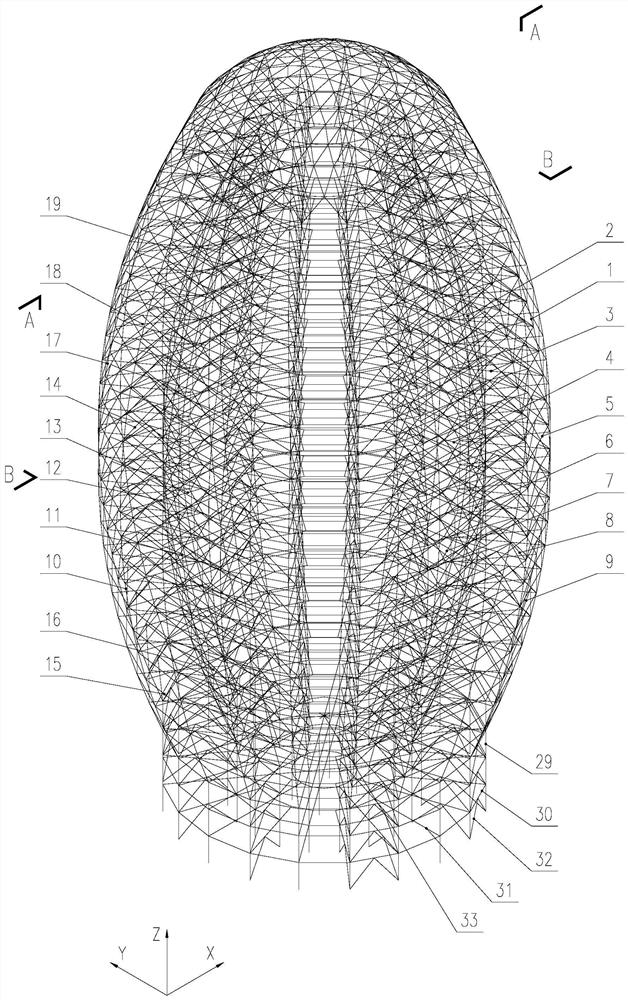

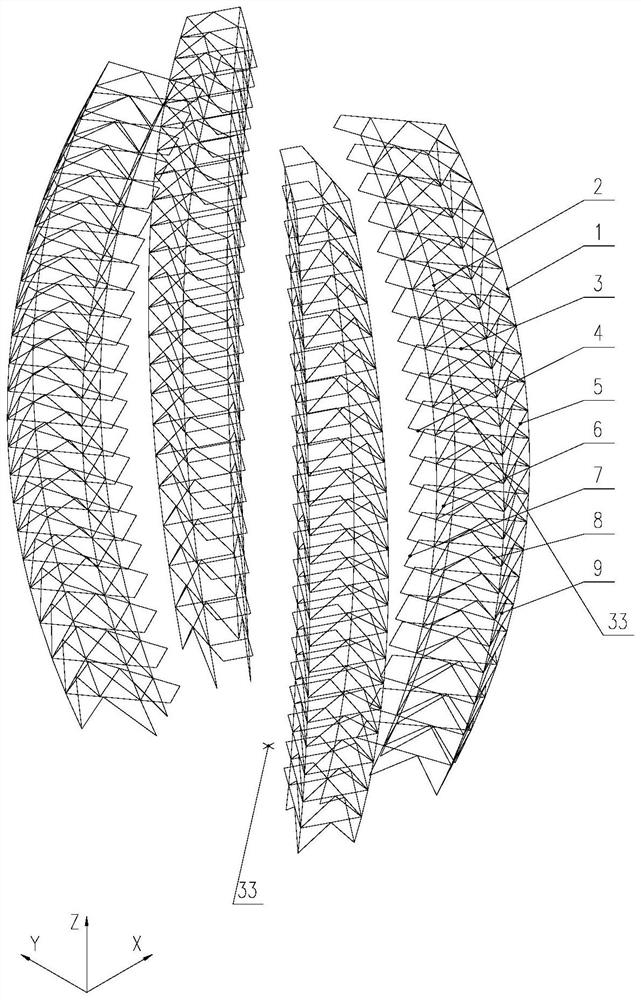

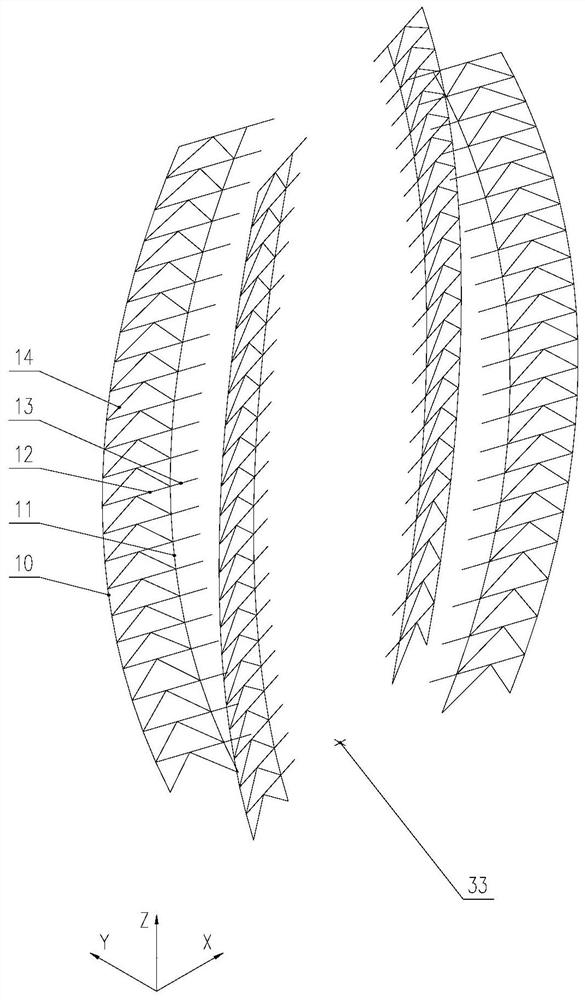

[0068] Such as Figures 1a-1h as well as Figure 2-Figure 4 As shown, the double-ring combined super high-rise structure based on the facade arc-shaped steel frame-support includes a steel support small frame tube, a steel support plane frame, inner and outer ring steel beams, unsupported steel beam columns, roof conversion trusses, Single-layer dome reticulated shell, bottom base structure; the steel support small frame tube ( Figure 1b ) is located in the elevator shaft of the building at the four corners of the plane. It consists of a single-span two-way steel frame-support to form a single steel support small frame tube with an arc-shaped facade. Constitute a lateral force resistant core support frame composed of multiple groups of single steel support small frame tubes; the steel support plane frame ( Figure 1c ) is located on both sides of the plane, and is composed of single-span and one-way steel frame-supports to form an arc-shaped single-panel steel-supported plan...

Embodiment 2

[0087] Such as Figure 10 As shown, the specific component composition process of the double-ring combined super high-rise structure based on the facade curved steel frame-support is as follows:

[0088] S1. The outer arc frame column 1 of the steel support small frame tube, the inner arc frame column 2 of the steel support small frame tube, the radial steel beam frame tube section of the steel support small frame tube 3, the radial steel frame tube of the steel support small frame tube Beam cantilever section 4, outer ring steel beam of steel supporting small frame tube 5, inner ring steel beam of steel supporting small frame tube 6, cantilever end ring steel beam of steel supporting small frame tube 7, steel supporting small frame tube The radial support 8 and the outer ring support 9 of the steel support small frame tube form a single steel support small frame tube;

[0089] S2. The outer arc frame column 10 of the steel support planar frame, the inner arc frame column 11 ...

Embodiment 3

[0099] The present invention also provides an application of a double-ring composite super high-rise structure based on the facade arc-shaped steel frame-support in the design and bearing of the double-ring floor space and the curved facade building modeling super high-rise structure system with a high atrium inside. The super high-rise refers to the structural height not less than 100 meters, and the double-ring combination refers to the floor space of the double-ring combination with the atrium as high as the whole.

[0100] Compared with the deficiencies of the prior art, the present invention provides a double-ring combination super high-rise structure based on a facade arc-shaped steel frame-support based on a combination of a steel support small frame tube and a steel support plane frame. The overall structure of the high-rise is to carry out ring rigid connection and roof structure conversion through the inner and outer ring steel beams and roof conversion trusses, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com