Angle brace type energy-consuming K-brace modular side-resistant unit structure

A unit structure, modular technology, applied in building components, building structures, protective buildings/shelters, etc., can solve the problems of difficult to find the location of supports, single building pattern, difficult construction of floor reinforcement, etc. Bearing capacity and stability, improve lateral resistance, meet the effect of flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with accompanying drawing:

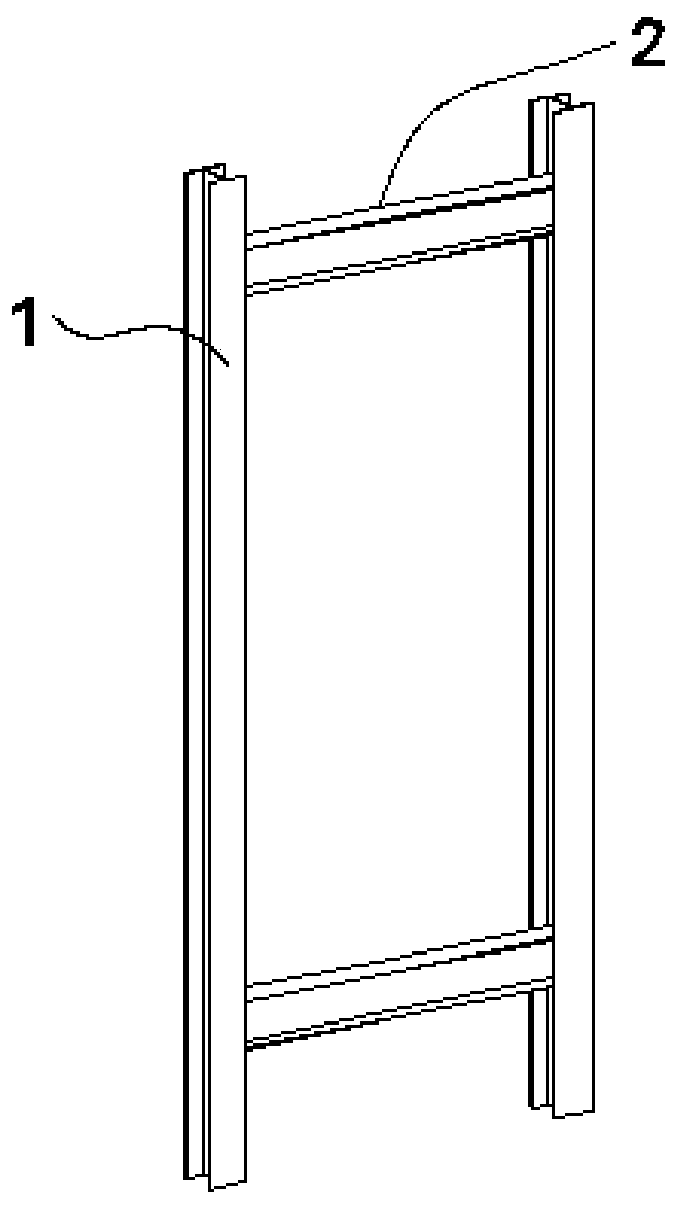

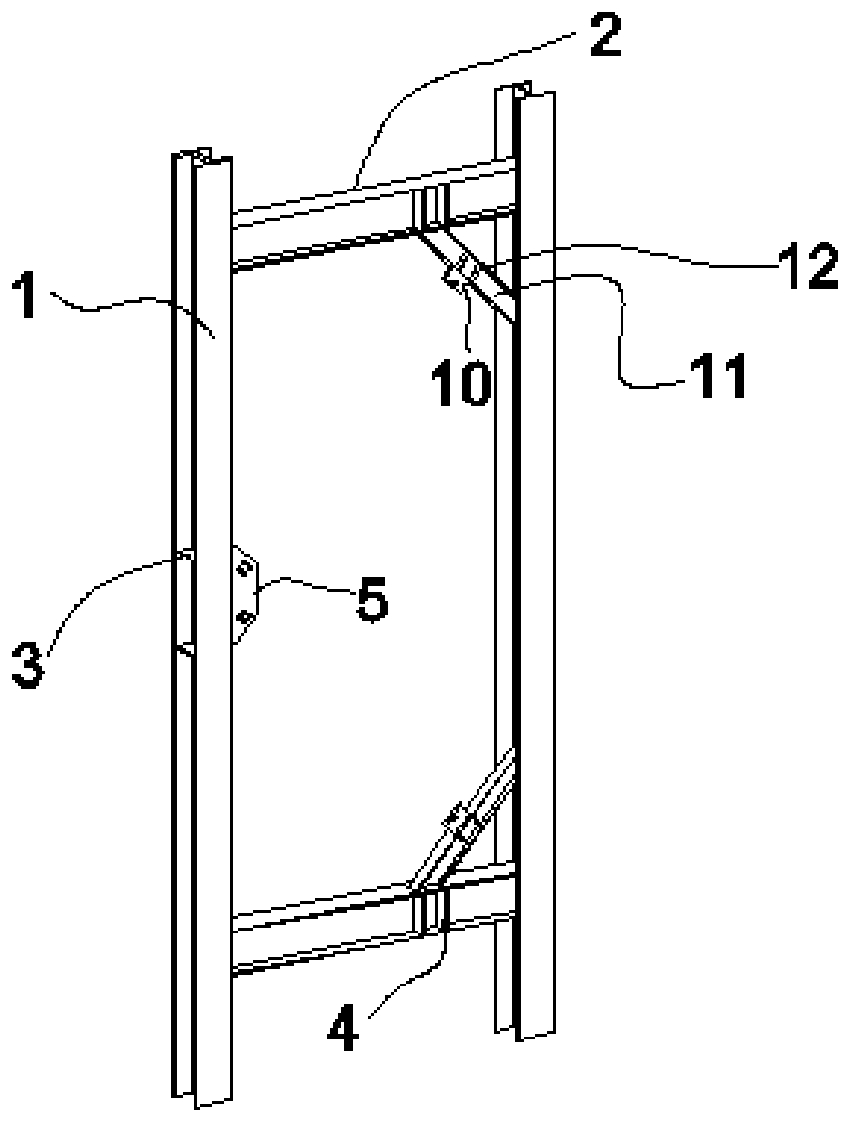

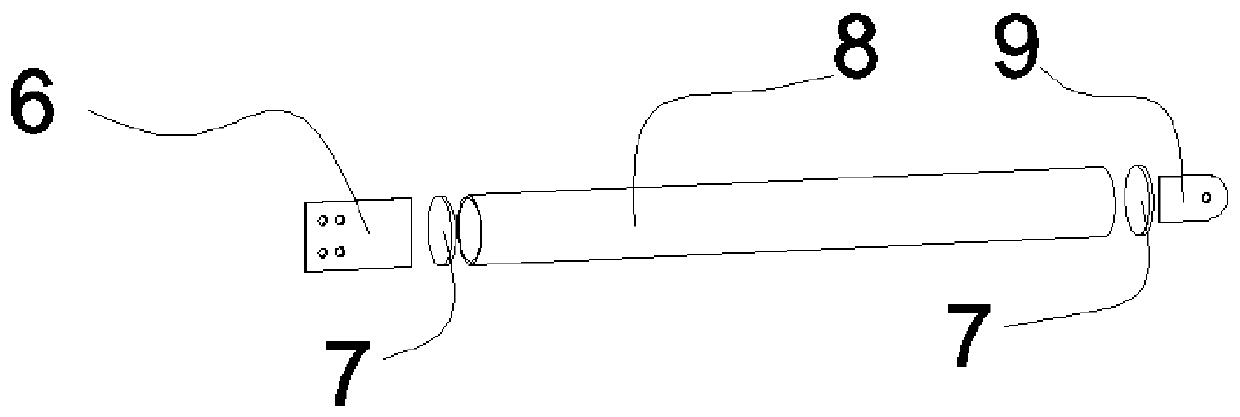

[0022] see Figure 1 to Figure 4 , a corner brace type energy-dissipating K brace modular anti-side unit structure, including a vertical brace 1, a horizontal brace 2, a diagonal brace and a corner brace 11; two vertical braces 1 are arranged in parallel, and two vertical braces Two horizontal struts 2 are vertically arranged between the rods 1 to form a rectangular frame structure; a corner strut 11 is provided at the connection between a vertical strut 1 and two horizontal struts 2; one end of the two diagonal supports is hinged In the middle part of another vertical brace 1, the other ends of the two diagonal supports are respectively hinged at the middle part of the two corner braces 11; Ear plates 9 ; end plates 7 are welded at both ends of the diagonal struts 8 , one end plate 7 is vertically fixed with a diagonal strut connecting plate 6 , and the other end plate 7 is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com