Pipe gallery prefabricated parts and assembly type rectangular comprehensive pipe gallery

A technology of prefabricated parts and pipe gallery, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of complicated procedures, long construction period and large construction site of cast-in-place pipe gallery, and achieve simple structure and construction period. The effect of shortening and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

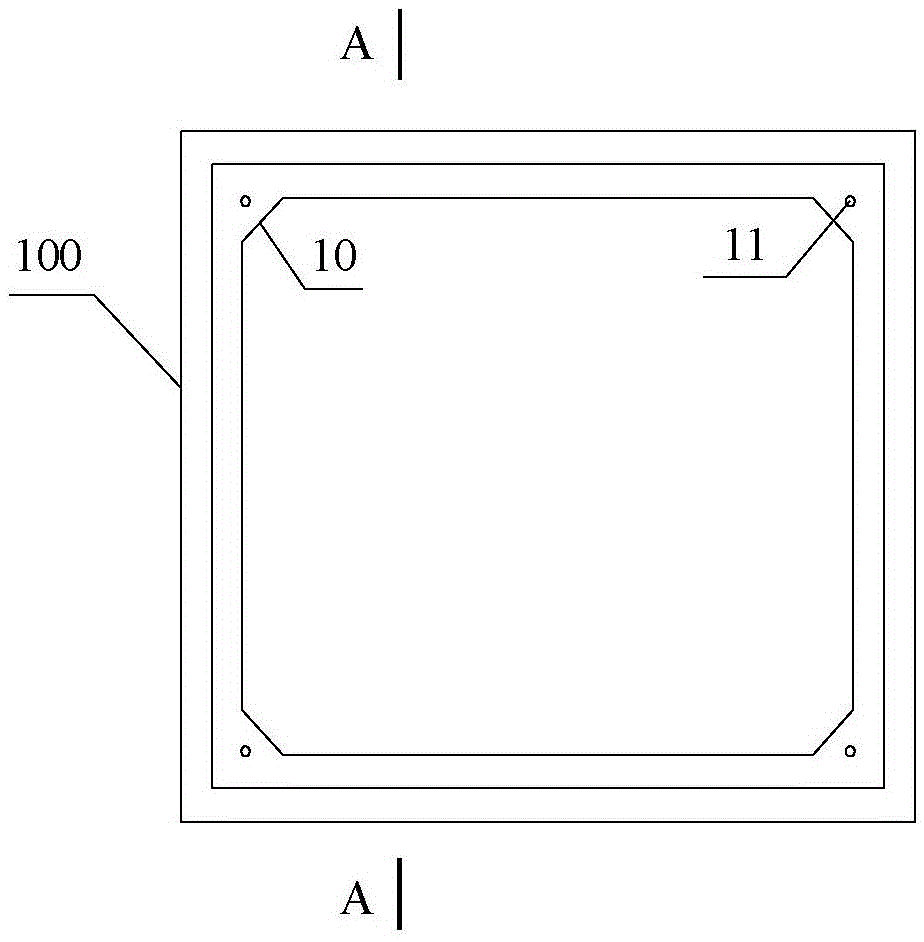

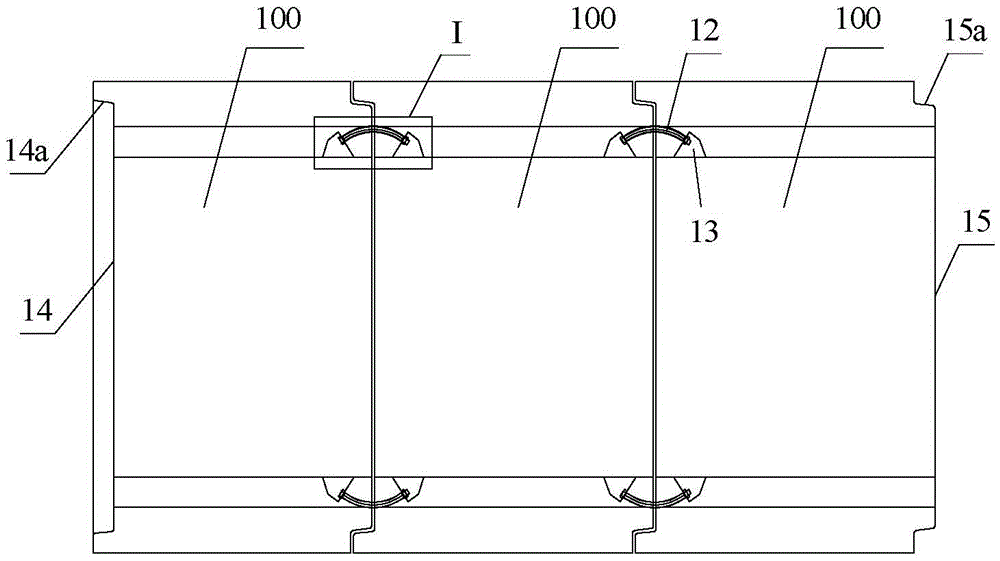

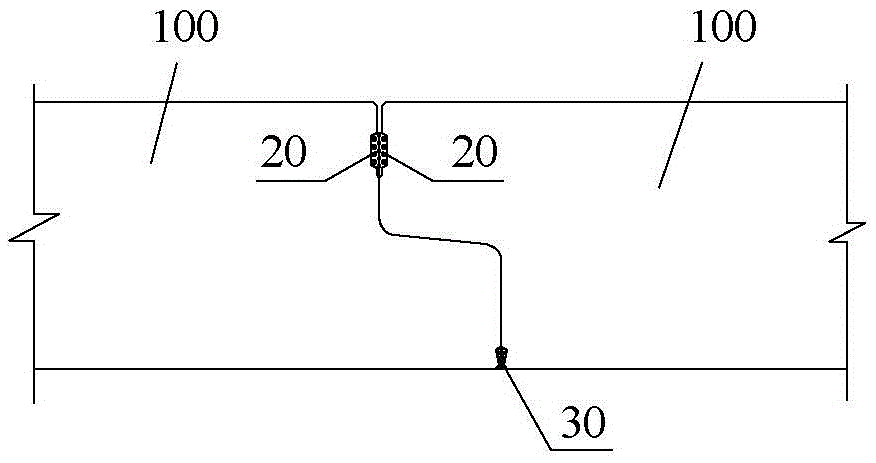

[0053] Such as figure 1 , figure 2 , image 3 As shown, the pipe gallery prefabricated part of the present invention includes a rectangular pipe section body 100 with a rectangular cross section along the length direction of the pipe gallery. The portion 15a is arranged annularly along the port, and fits with the correspondingly provided annular notch 14a of the socket end 14 .

[0054] Each corner of the insertion end 15 and the socket end 14 is respectively provided with a bolt connection hole 11 whose axis is a plane arc line. Hand hole 13 for nut. When the two sections of pipe gallery prefabricated parts 100 are plug-fitted, the corresponding bolt connection holes 11 at the plug-fit parts are butted to form the bolt connection holes connecting the two pipe gallery prefabricated parts 100 that are plug-fitted.

[0055] Usually, the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com