Large stepping type rotating pulse desuter

A pulse dust collector and step-by-step technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of difficulty in localization and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

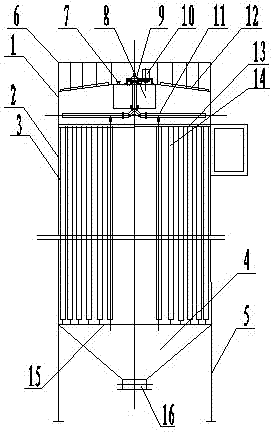

[0031] A large-scale stepping rotary pulse dust collector of the present invention can be made of steel structure or composite material. The use of composite materials is more conducive to the realization of factory production, and the module structure is made in the factory and assembled on site.

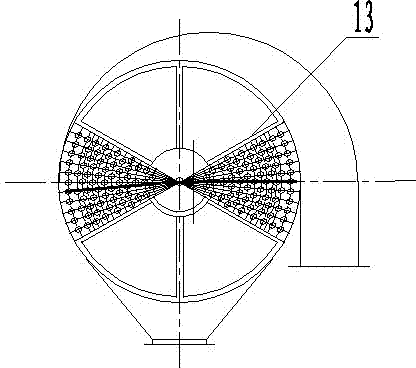

[0032] According to the processing air volume, filter area, filter area of a single unit, the number of filter bags can be adjusted. When the number of filter bags in a set is less than 414, only two spray pipes with a mutual angle of 175° can be set.

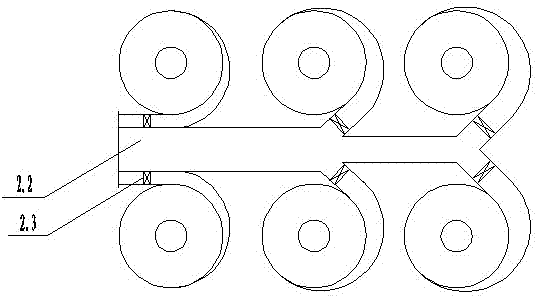

[0033] The extra-large stepping rotary pulse dust collector is a modular structure, only need to configure the air inlet variable diameter pipe 2.2, the air outlet variable diameter pipe 2.4 and the pneumatic ash conveying system, and connect multiple stepping rotary pulse dust collectors in parallel use.

[0034] The present invention will be further described with reference to the accompanying drawings. Its structure mainly inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com