Prefabricated type reinforced concrete underground comprehensive pipe gallery and production mold thereof

A prefabricated assembly and comprehensive pipe gallery technology, which is applied in the direction of manufacturing tools, underwater structures, water conservancy projects, etc., can solve the problems of hidden dangers in the safety and durability of the comprehensive pipe gallery structure, and poor integrity, so as to shorten the on-site construction period, The effect of reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

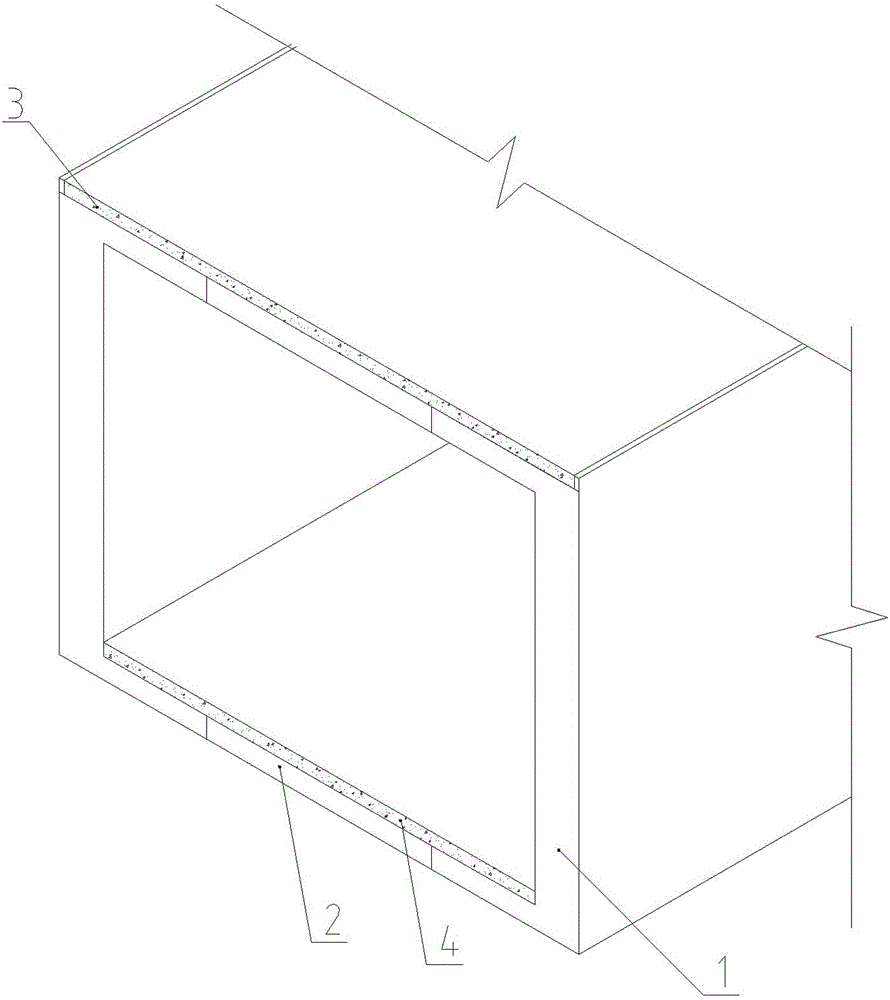

[0027] Embodiment one, such as figure 1 As shown, this embodiment discloses a single-channel prefabricated reinforced concrete underground comprehensive pipe gallery, which is formed by sequentially arranging several integral unit sections. The skeleton plate of the integral unit section includes two channel steel prefabricated reinforced concrete panels 1 and two prefabricated reinforced concrete panels 2, the two channel steel prefabricated reinforced concrete panels 1 are symmetrically arranged left and right, and the prefabricated reinforced concrete panels 2 are spliced in the two grooves between steel prefabricated reinforced concrete panels 1 . An integral unit section is formed by post-cast reinforced concrete composite layer 3 on the top surface and post-cast reinforced concrete laminated layer 4 on the bottom surface.

[0028] Such as Figure 5 As shown, the channel-type prefabricated reinforced concrete panel 1 is a channel-type prefabricated integral part surro...

Embodiment 2

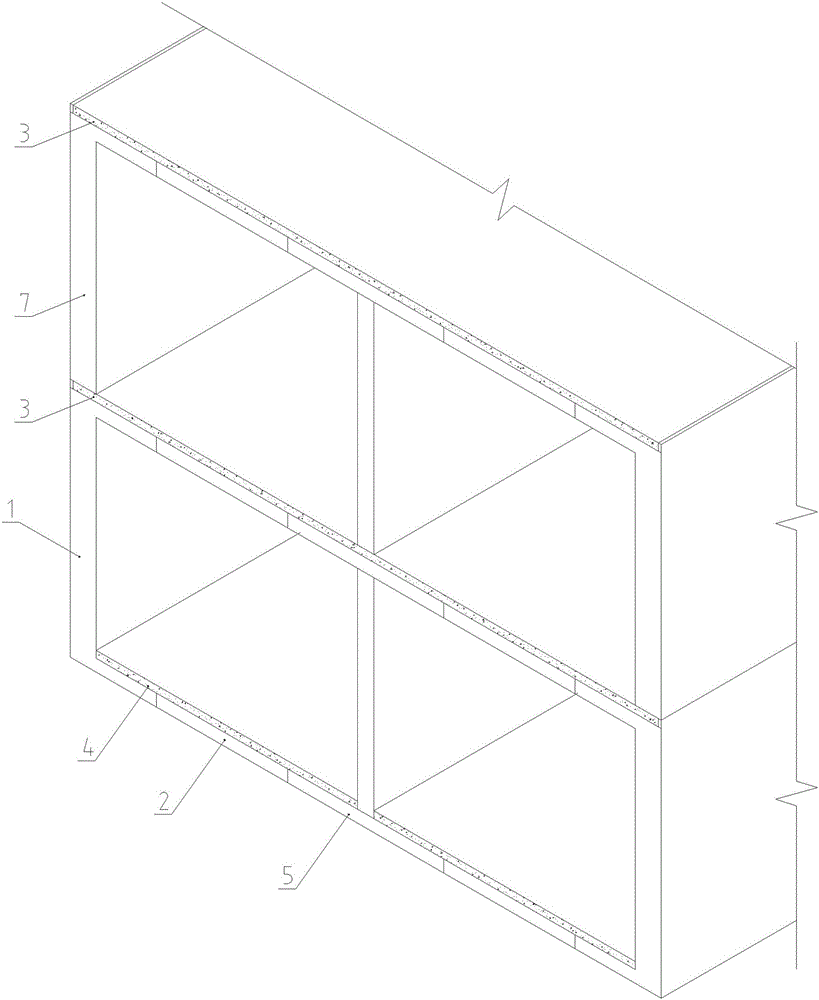

[0031] Embodiment two, such as figure 2 As shown, this embodiment discloses a prefabricated assembled reinforced concrete underground comprehensive pipe gallery with left and right double channels. Concrete slab 2 and a prefabricated reinforced concrete slab 5 of I-shaped steel. The two-channel steel-shaped prefabricated reinforced concrete slab 1 is arranged symmetrically on both sides, the I-shaped steel-shaped prefabricated reinforced concrete slab 5 is arranged in the middle, and the prefabricated reinforced concrete slab 2 is spliced on the upper wing of the I-shaped steel-shaped prefabricated reinforced concrete slab 5 between. An integral unit section with two left and right passages is formed by the post-cast reinforced concrete laminated layer 3 on the top surface and the post-cast reinforced concrete laminated layer 4 on the bottom surface. The structure of the channel steel type prefabricated reinforced concrete panel 1 and the prefabricated reinforced concrete...

Embodiment 3

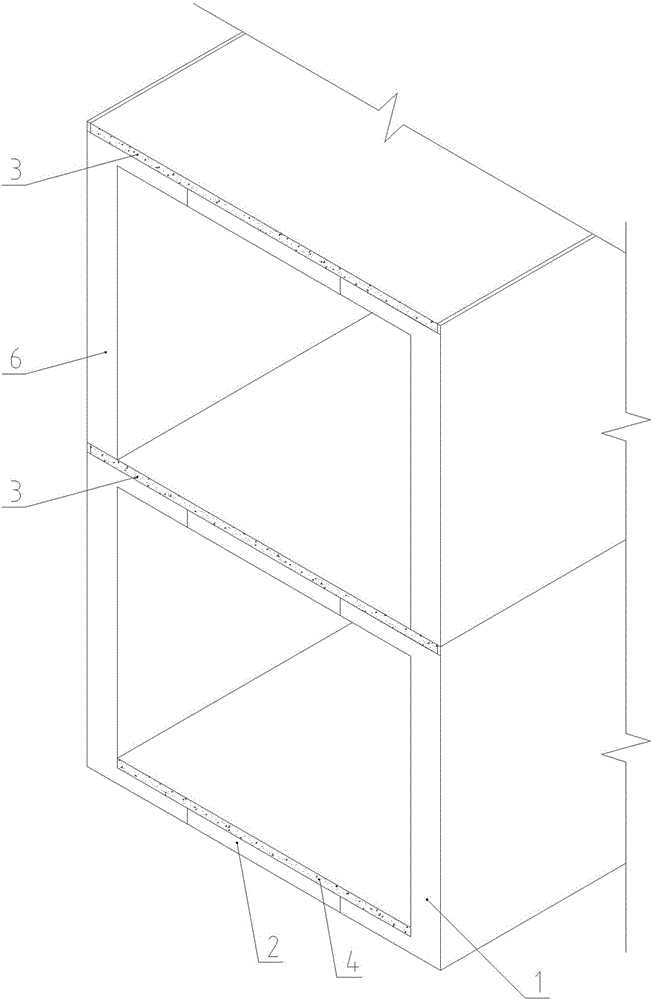

[0034] Embodiment three, such as image 3 As shown, this embodiment discloses an assembled integrated reinforced concrete underground comprehensive pipe gallery with upper and lower double channels. The integral unit section skeleton of this embodiment is added with two L-shaped prefabricated reinforced concrete panels on the basis of the first embodiment. 6 and a prefabricated reinforced concrete slab 2 surround the upper passage.

[0035] Such as Figure 7 As shown, the structure of the L-shaped prefabricated reinforced concrete slab 6 is a structure obtained by removing the bottom plate of the channel-shaped prefabricated reinforced concrete slab 1 .

[0036] During construction, first complete the construction of the lower channel according to the construction process of Embodiment 1, and then complete the construction of the upper channel with reference to the construction process of Embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com