Bendable coated composite veneer

A composite wood and coating technology, which is applied in the direction of wood processing equipment, wooden veneer joints, layered products, etc., can solve the problems of inconvenient construction, high cost of use, and inability to bend, so as to shorten the construction period, The effect of low cost of use and avoiding trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

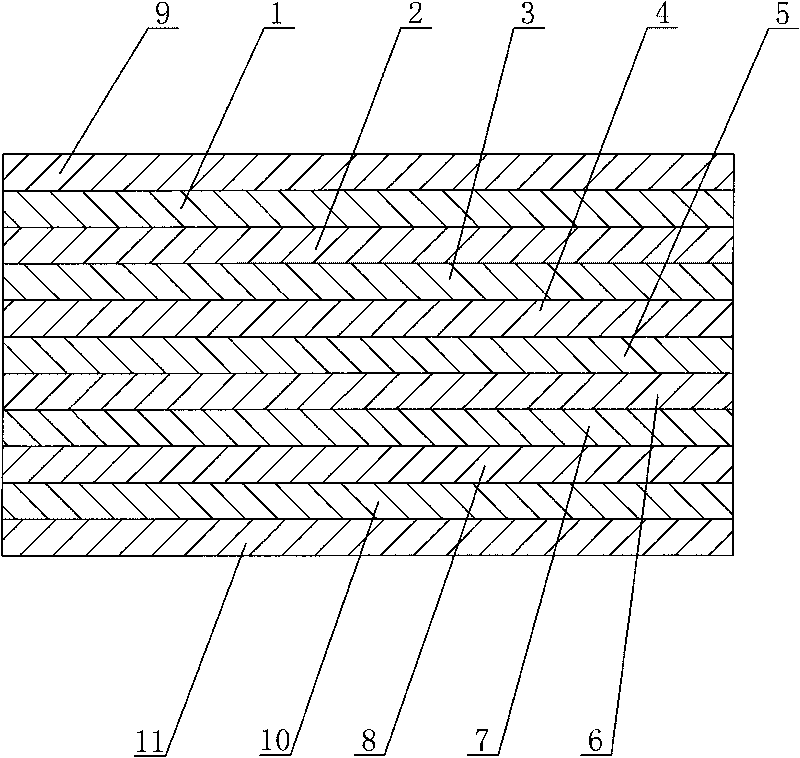

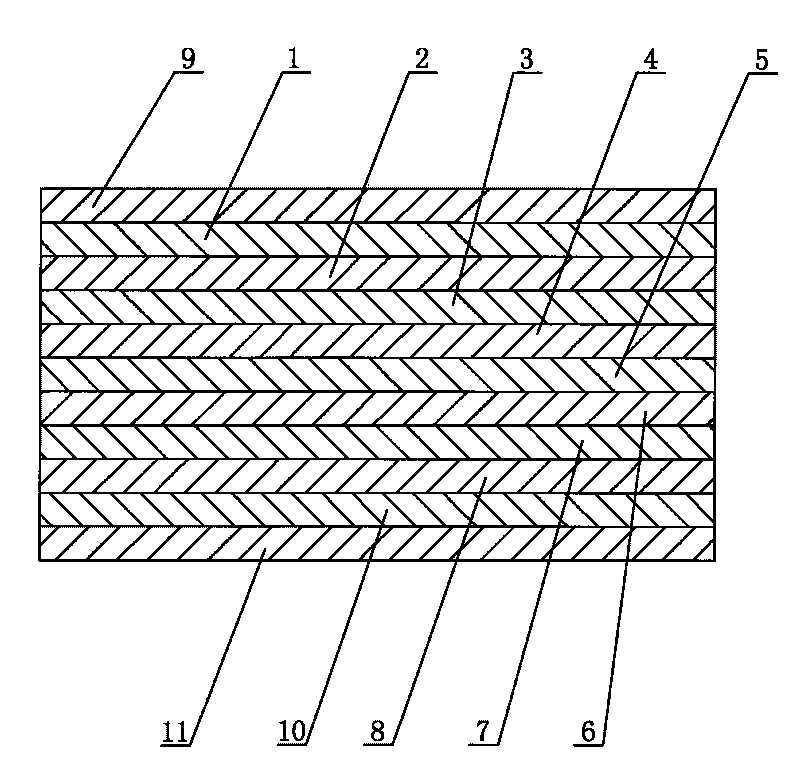

[0012] Such as figure 1 As shown, the composite veneer can be bent and painted, and the paint layer 1, the dyed veneer layer 2, the first glue layer 3, the outer paper layer 4, the second glue layer 5, the aluminum foil layer 6, the third Glue layer 7 and inner paper layer 8. In this embodiment, a polyvinyl chloride plastic protective layer 9 is provided on the outside of the paint layer 1, and an adhesive preparation layer is arranged on the inner side of the inner paper layer 8, and the adhesive preparation layer is arranged on the The fourth glue layer 10 inside the inner paper layer 8 is composed of a protective paper layer 11 arranged inside the fourth glue layer 10 . In actual production, printed marks can also be set on the inner side of the inner paper layer 8, and the printed marks can be marks such as print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com