Device for assembling stand column with bearing platform of bridge

A technology for assembling devices and columns, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of long construction period on site, large impact on the surrounding environment, unstable quality of concrete pouring on site, etc., achieve high construction period and reduce project cost , The effect of stable and controllable component quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

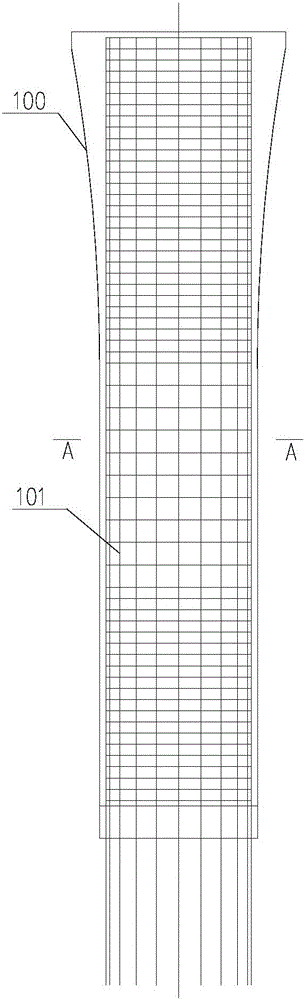

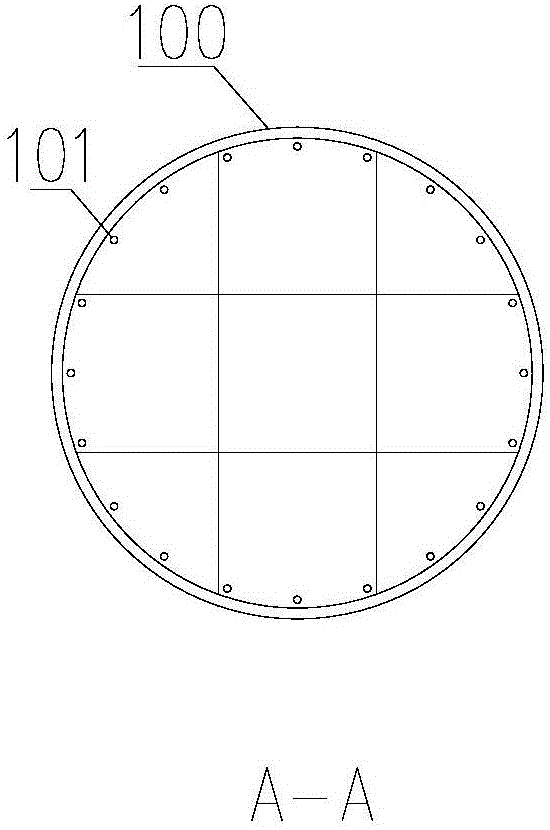

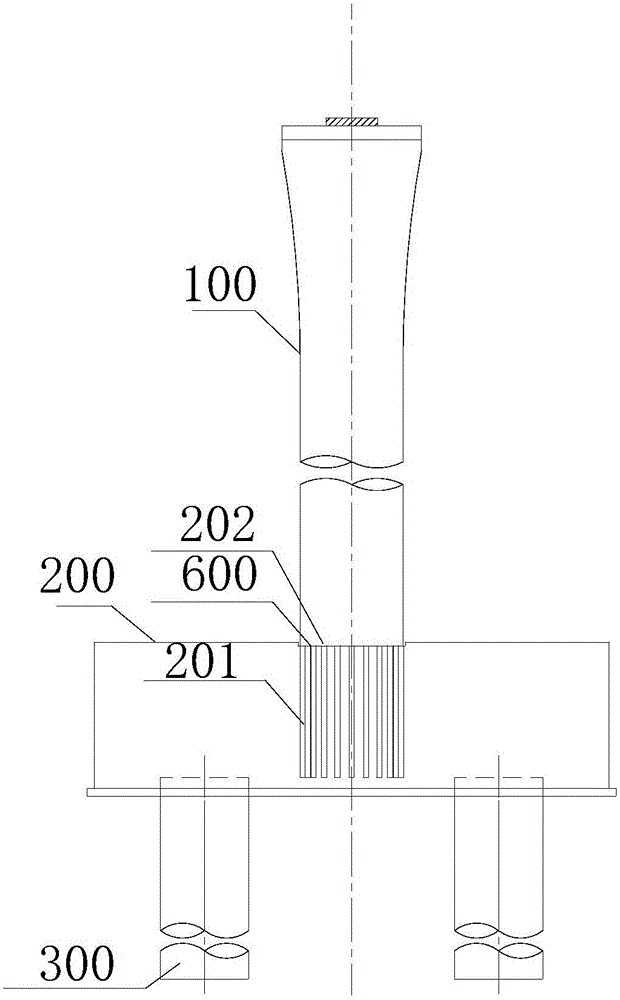

[0028] Such as Figure 1 to Figure 4 As shown, an assembly device for a bridge column and a cap is characterized in that it is used for assembling a bridge column 100 and a cap 200, and the assembly device includes: several column steel bars 101 protruding from the bottom of the bridge column 100; A plurality of metal bellows 201 buried in the platform 200. The length direction of the metal bellows 201 is parallel to the vertical direction of the platform 200; 101 corresponds to the position and quantity; when the bridge column 100 and the cap 200 are assembled, the column reinforcement 101 is inserted into the metal bellows 201 correspondingly, and then, after the bridge column 100 and the cap 200 are assembled A joint material 600 is provided at the joint, and the joint material 600 is selected from one of hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com