Universal adjusting jig frame system for assembling unit bodies

A technology for universal adjustment and assembling unit, applied in the field of tire frame system and assembling unit body, can solve the problems of inability to guarantee the precise position of a single component, difficulty in ensuring assembly accuracy and quality, affecting on-site construction, etc. High efficiency, low cost, and the effect of ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structural features of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

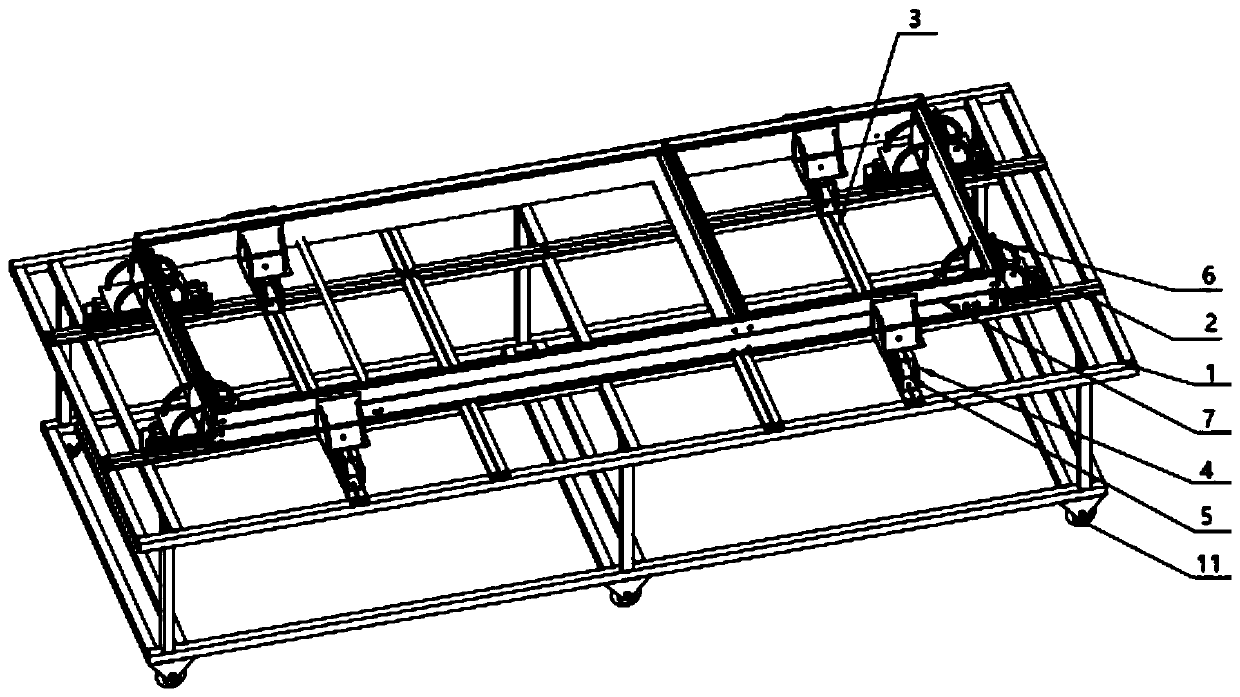

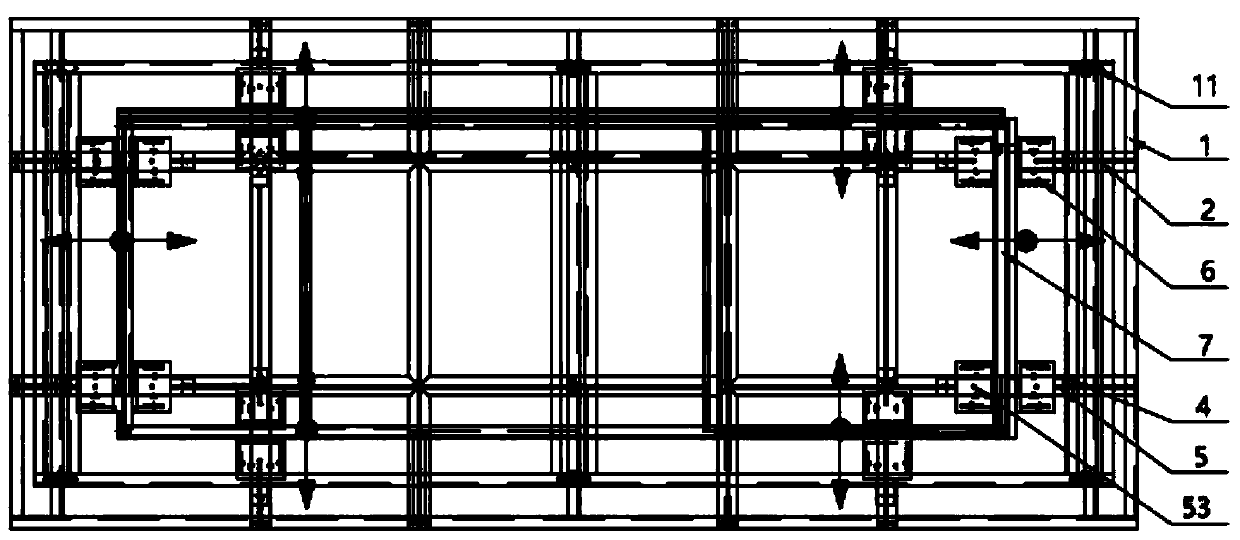

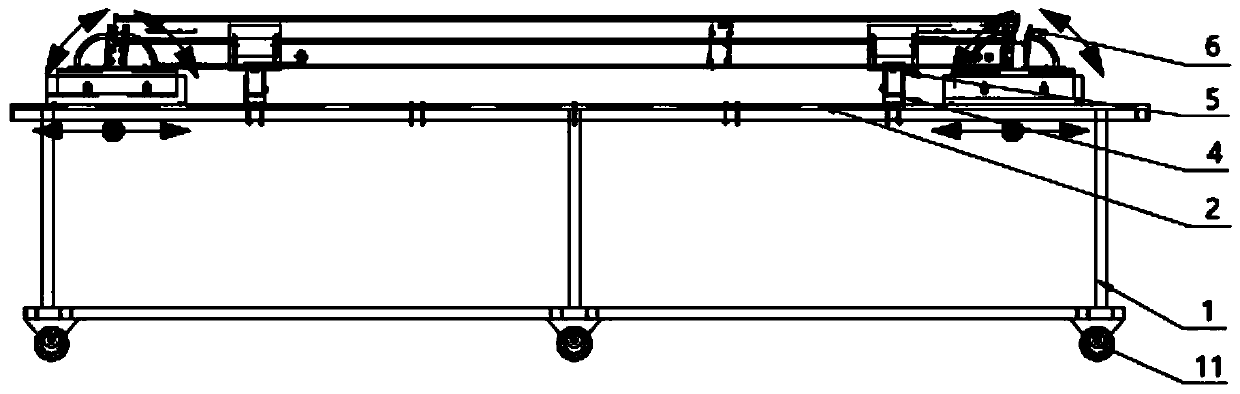

[0023] Such as figure 1 , Figure 2A-Figure 2C As shown, the universally adjustable tire frame system for assembling unit bodies disclosed in the present invention includes a workbench 1, at least two transverse rails 2, at least two longitudinal rails 3, and at least two U-shaped grooves installed on each rail 4. A square channel 5 installed in each U-shaped groove, and two aluminum alloy hinge corner components 6 installed on each square channel.

[0024] Described workbench 1 is a rectangular / cuboid frame, is welded with several horizontal reinforcing ribs and vertical reinforcing ribs in the frame, and universal wheels 11 are installed at its bottom four corners. In a specific embodiment of the present invention, the workbench is welded by 60mmX5mm galvanized square, which not only meets the strength requirements, but al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com