Continuous zooming driving magnet yoke group and assembling method thereof, lens driving device and camera device

An assembly method and a technology of a yoke group are applied in the field of a lens driving device, a camera device, and a continuous zoom driving magnetic yoke group, which can solve the problems such as the increase of the final motor volume, the unreasonable design, the long matching stroke, etc., and achieve the reduction of radial direction. The effect of size, prolonging service life, ensuring assembly efficiency and assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

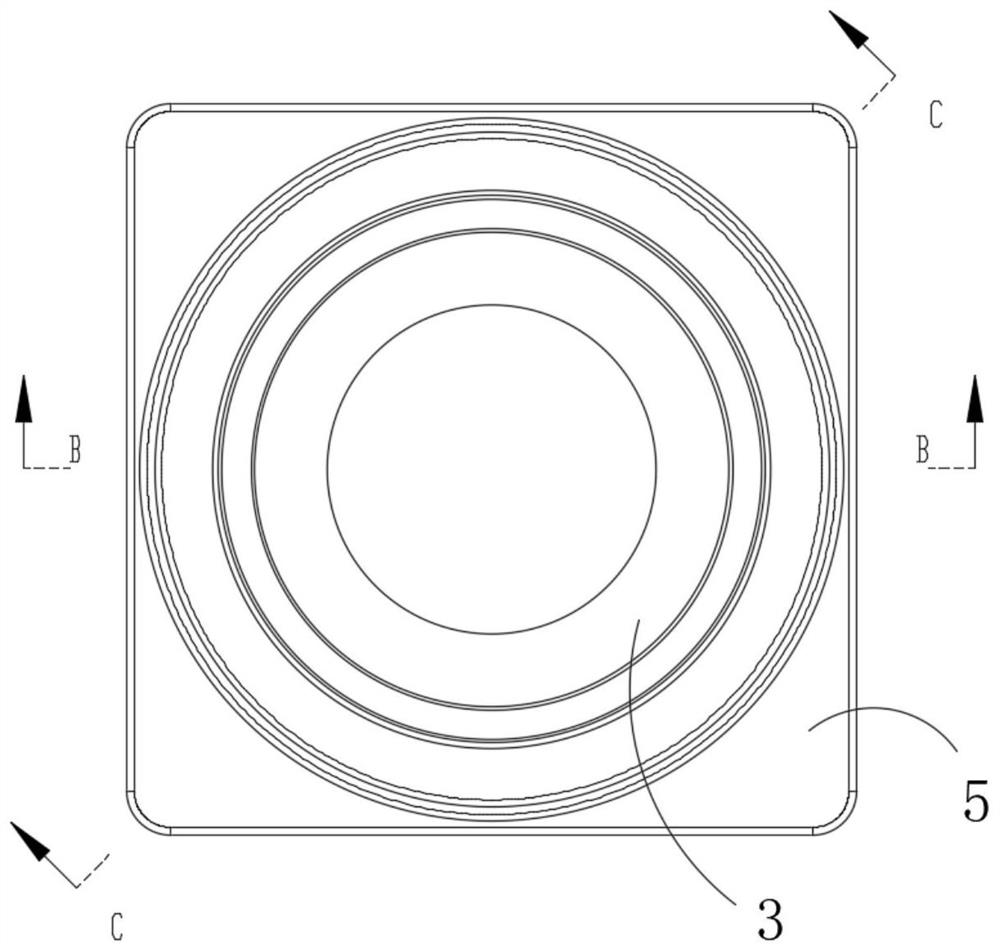

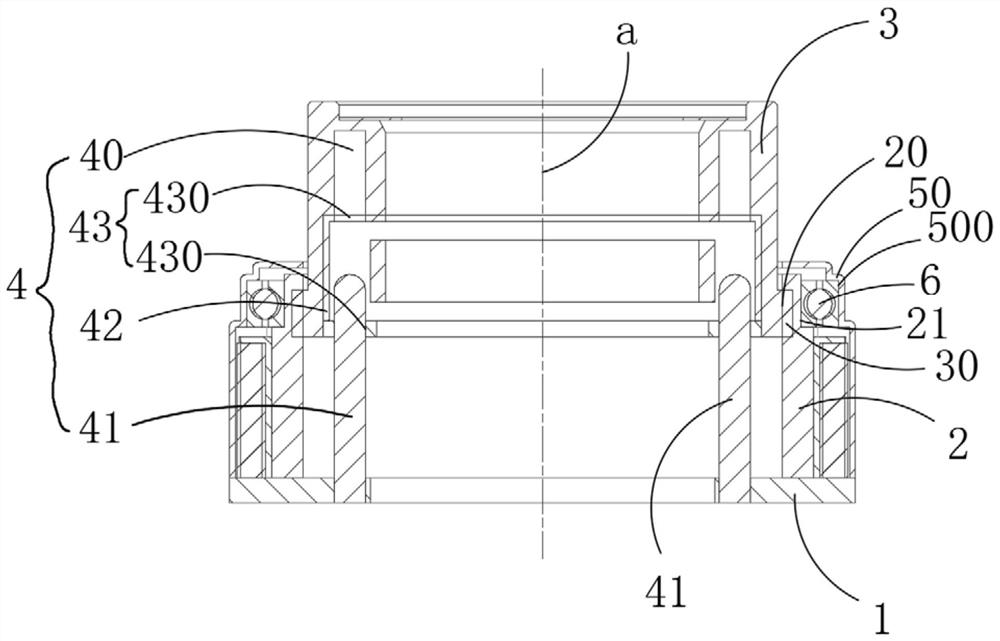

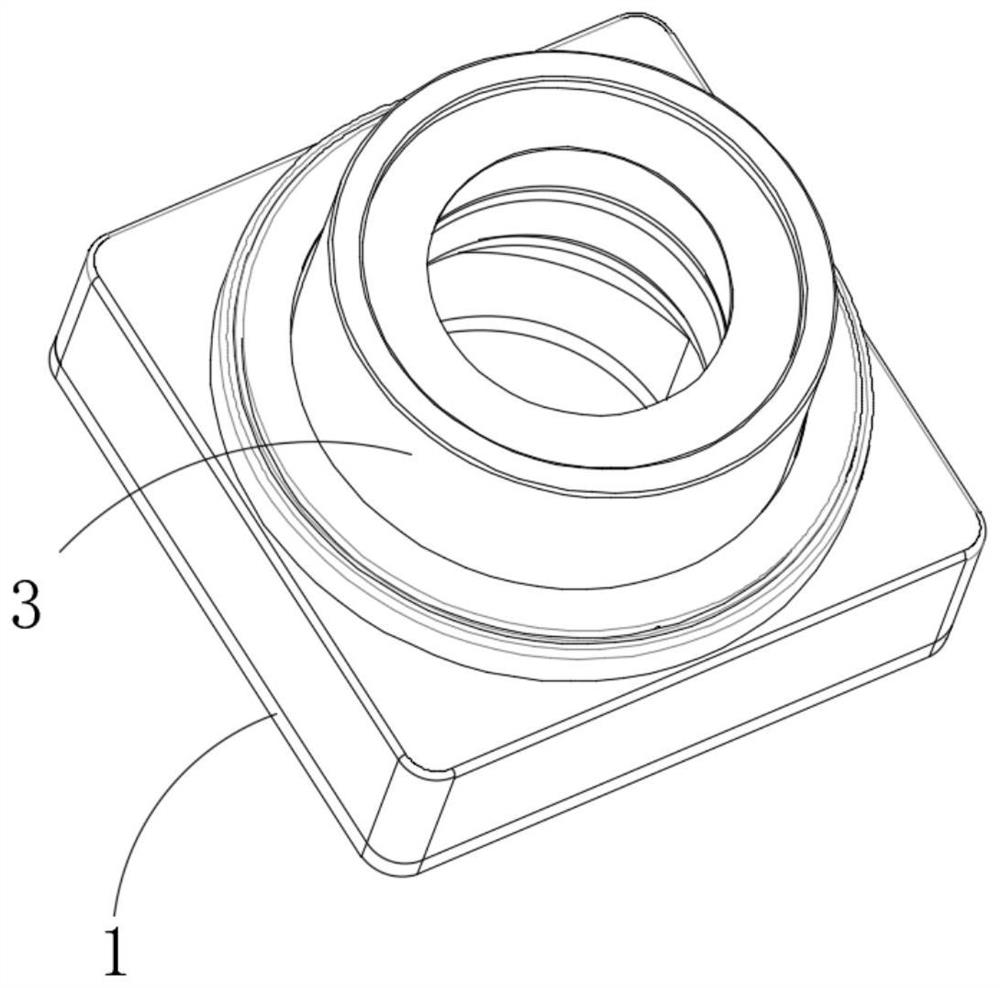

[0048] like Figure 4 and Figure 9 - Figure 10 As shown, the lens driving device includes a continuous zoom driving yoke group, in particular, the continuous zoom driving yoke set of the present embodiment is located in a chamber formed by the base 1 and the outer casing 5, the yoke group including a tube 2, a rotor magnetic Yoke 70 and the stator yoke 80.

[0049] The drum 2 is built into the chamber and the axial direction is rotatably connected to the outer casing 5, and the rotor 2 is fixed axially opposite the outer casing 5, and the axial direction of the drum 2 is extended to the base 1 side and is free;

[0050] The rotor is fixed to the base and can be rotated, in which the length of the rotor is largely shortened, and the rotor yoke and the stator yoke are greatly shortened in the axial direction of the optical axis, which can be reduced. The optical axis length of the small lens driving device can be applied to a thinner or ultra-thin imaging terminal.

[0051] The rotor...

Embodiment 2

[0108] like image 3 As shown, the lens driving device has a continuous zoom driving yoke group according to the first embodiment.

Embodiment 3

[0110] like Figure 7 As shown, the imaging device has a lens driving device according to the second embodiment, and a lens is mounted on the lens driving device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com