Novel building material of fiberglass composite structure, production device and production method

A glass fiber composite and building material technology, applied in the direction of building components, building elements, chemical instruments and methods, etc., can solve the problems of complex manufacturing process, poor fire performance, easy aging, etc., to shorten the construction period and improve the bearing capacity , the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

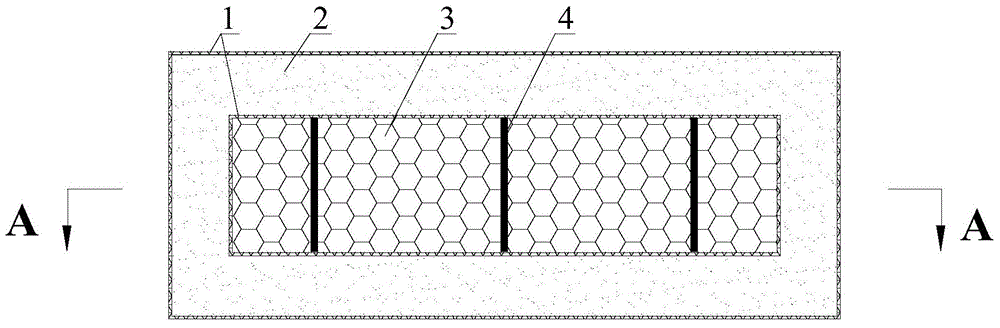

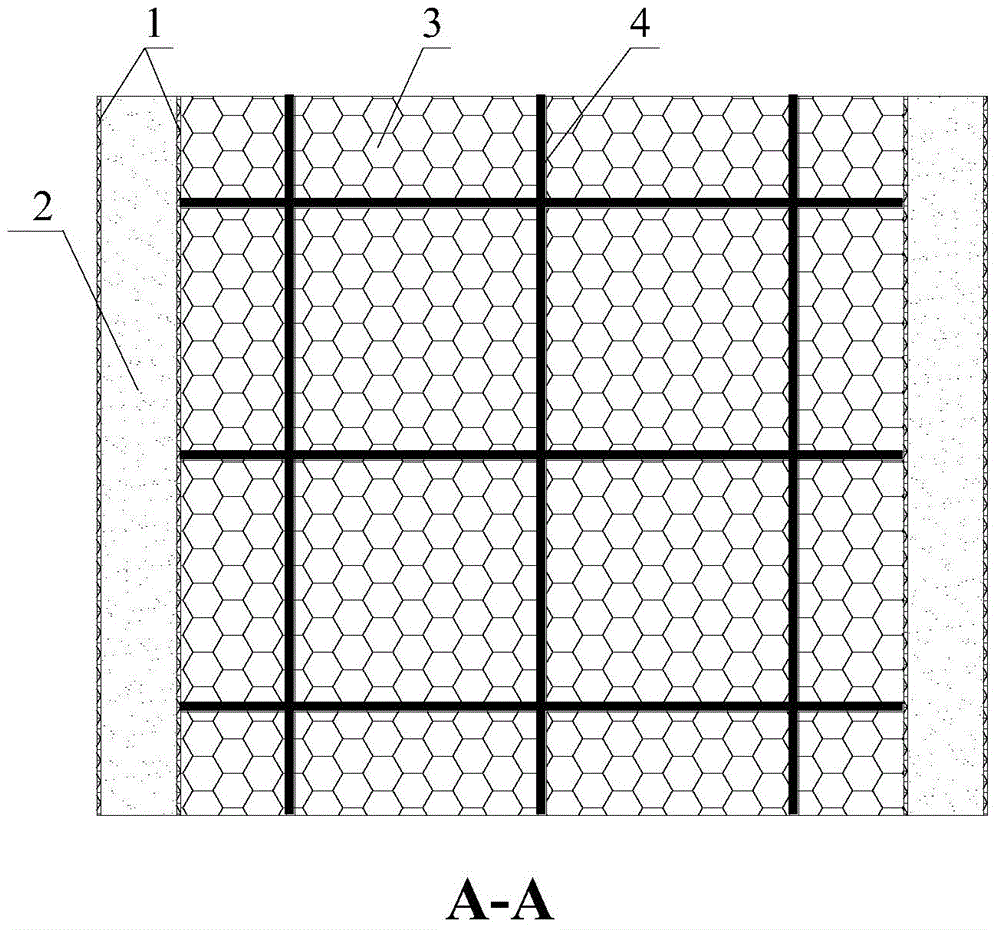

[0037] as attached figure 1 with attached figure 2 The building material of the new glass fiber composite structure shown includes a thermal insulation sandwich layer and a cement structure layer 2, and the cement structure layer 2 is wrapped around the thermal insulation sandwich layer; the thermal insulation sandwich layer includes a reinforced structural frame 4 and thermal insulation foam material 3, the thermal insulation foam material 3 fills the void area in the reinforced structural frame 4; the material of the cement structure layer 2 is cement; the thermal insulation sandwich layer and the cement structure layer 2 There is a layer of glass fiber layer 1 between them, and a layer of glass fiber layer 1 is also wrapped around the outside of the cement structure layer 2 .

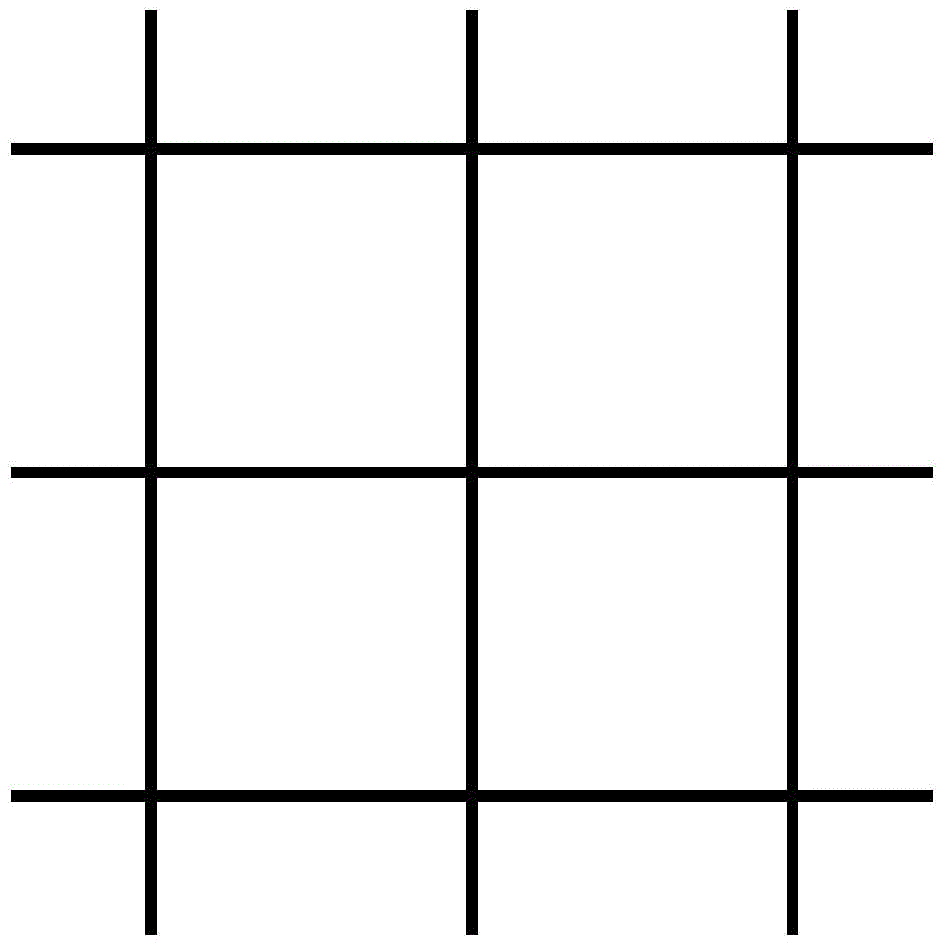

[0038] The reinforced structural frame 4 is made of grid plates, and the grid plates are built into a square frame arranged in a two-dimensional array, as shown in the attached image 3 As shown, th...

Embodiment 2

[0054] The overall structure of the building material of the new glass fiber composite structure is the same as that of Embodiment 1, but the reinforced structural frame 4 is formed by stacking three layers of grid plate frames 41 in the thickness direction, as shown in the attached Figure 7 with attached Figure 8 As shown, there is an intermediate plate 42 between adjacent grid plate frames 41, and the through holes arranged in a two-dimensional array are opened on the intermediate plate 42; each layer of grid plate frame 41 is built by a grid plate The grid plate is built into a square frame arranged in a two-dimensional array, and the two dimensions of the array are respectively the width direction and the height direction of the building material of the new glass fiber composite structure; the thermal insulation foam material 2 fills the entire reinforced structural frame All the void areas inside; wherein the grid plate and the intermediate plate 42 are made of organic ...

Embodiment 3

[0060] The overall structure of the building material of the novel fiberglass composite structure is the same as that of Embodiment 1, but the reinforced structural frame 4 is made of steel bars, as attached Figure 9 The steel bars shown are built into a cube frame arranged in a two-dimensional array, and the two dimensions of the array are respectively the width direction and the height direction of the building materials of the new glass fiber composite structure; each cube frame has at least one surface There is a reinforcing steel bar obliquely on the diagonal line above; the joints of the steel bars are welded or connected by steel wires, and the thermal insulation foam material fills the inner space of each cube frame.

[0061] In addition as attached Figure 10 As shown, the steel bars can also be built into a three-dimensional arrayed cube frame with several layers in the thickness direction, and the three dimensions of the array are the thickness direction, width dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com