Fast building earthquake-resisting reinforcing method and device

A technology for strengthening devices and houses, which is applied in earthquake resistance, building maintenance, building components, etc., can solve problems such as waste, difficulty in construction operations, and long consumption time, and achieves improved connection firmness, shortened site construction period, and improved pouring quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

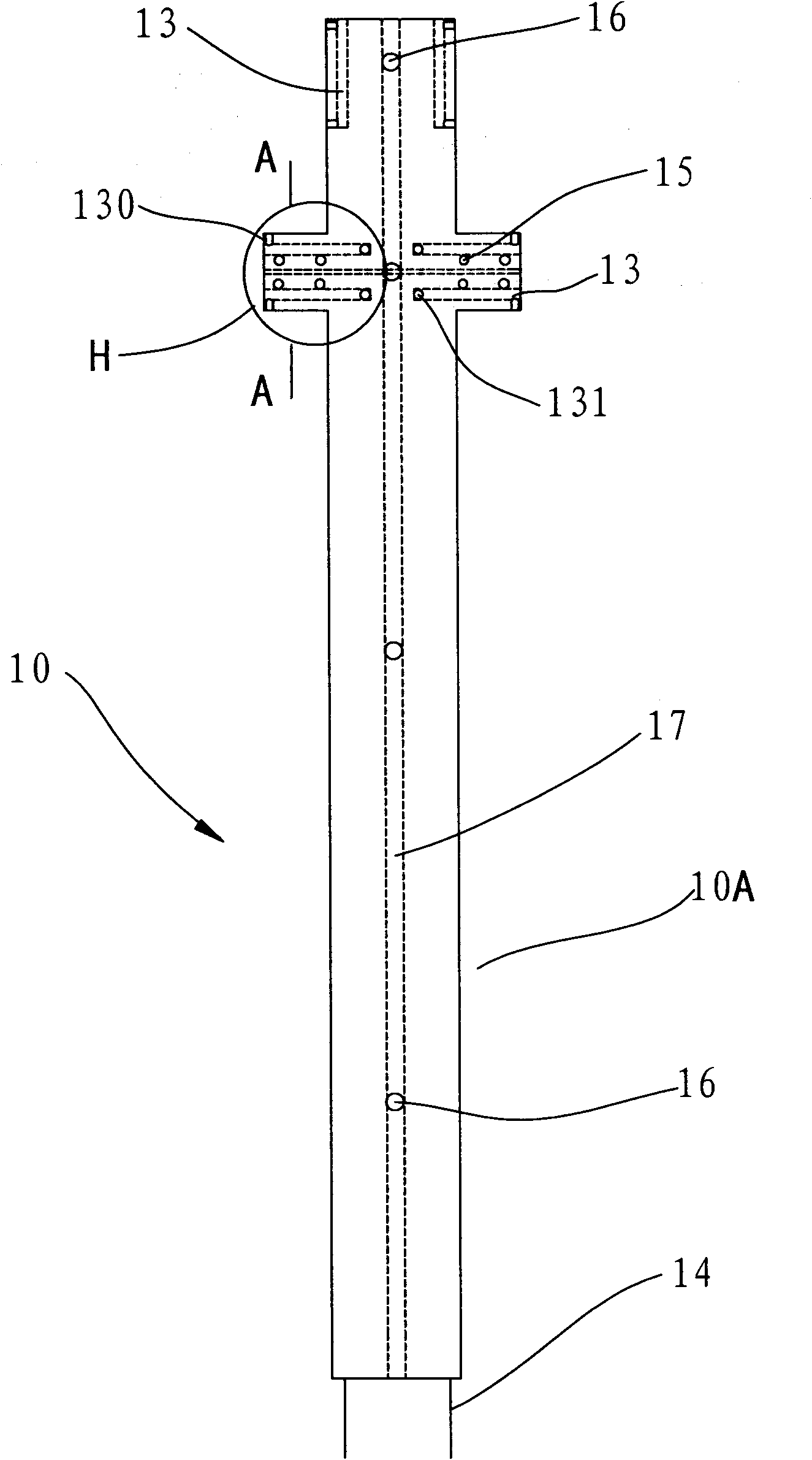

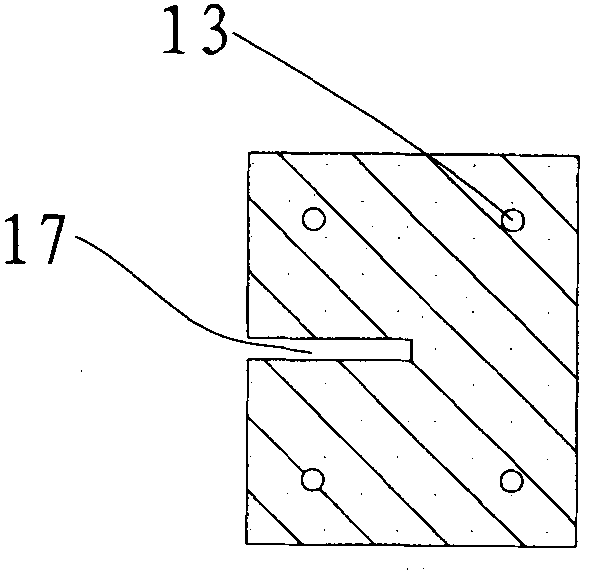

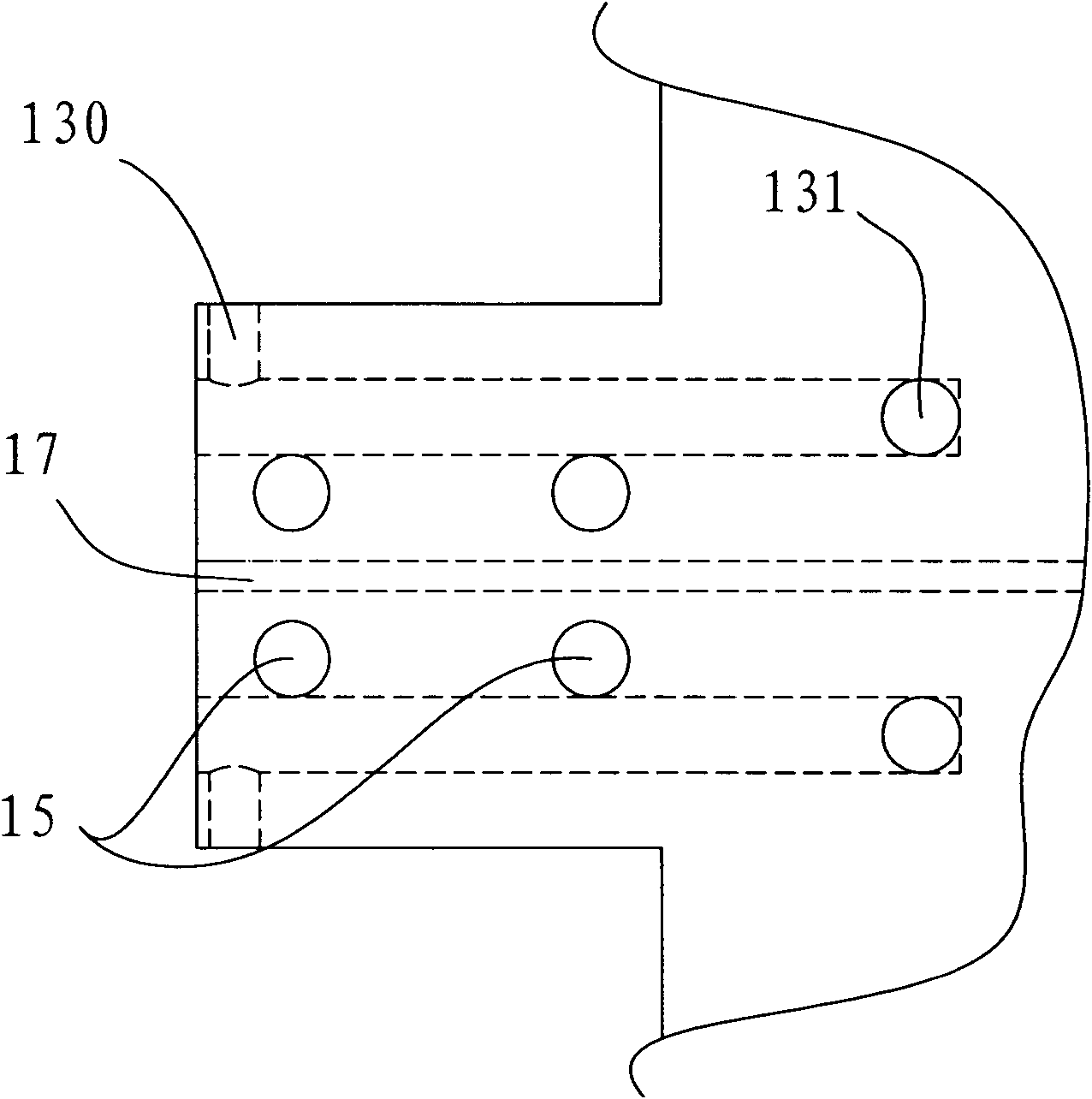

[0052] Picture 10 It is a schematic diagram of the connection structure between the prefabricated components of the present invention; Picture 11 , Picture 12 It is a schematic diagram of the connection structure between the prefabricated components of the present invention and the wall of the reinforced house, in which, Picture 11 Schematically shows the connection structure state of the structural column, ring beam and the wall of the reinforced house at the junction of the vertical and horizontal walls, Picture 12 Schematically shows the connection structure state of the external angle structural column, ring beam and the wall of the reinforced house; Figure 13A It is a schematic diagram of the externally pasted connection of the external angle structural column in the prefabricated component of the present invention with the wall; Figure 13B It is a schematic diagram of the externally pasted connection of the structural column at the junction of the vertical and horizont...

Embodiment approach 2

[0068] Another specific embodiment of the earthquake-resistant reinforcement method for a fast house proposed by the present invention is different from the above-mentioned embodiment one in that the inner side of the prefabricated member 10 and the wall surface of the reinforced house are separately coated with external stickers. , Paste the two together to achieve seismic reinforcement and reinforcement of the house. The specific steps are:

[0069] A. Cut off the surface of the connecting surface where the wall of the reinforced house 4 and the prefabricated member 10 are connected, and drill anchor holes on the wall of the reinforced house from which the surface is removed, so that the position of each anchor hole is consistent with The connecting holes on the prefabricated parts correspond.

[0070] And the wall body of the reinforced house 4 and the connecting surface of the prefabricated member 10 are respectively coated with an external adhesive bonding material, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com