Prefabricated concrete large box girder structure connected in transverse bridge direction through dry connecting method

A precast concrete, transverse bridge technology, applied in bridges, infrastructure engineering, construction, etc., can solve the problem of bridge structure construction period control, construction cost control trouble, not meeting the landscape requirements of departments, and inconvenient movement of bridge erection equipment. problem, to achieve the effect of flexible construction method, good landscape effect and reduction of on-site construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

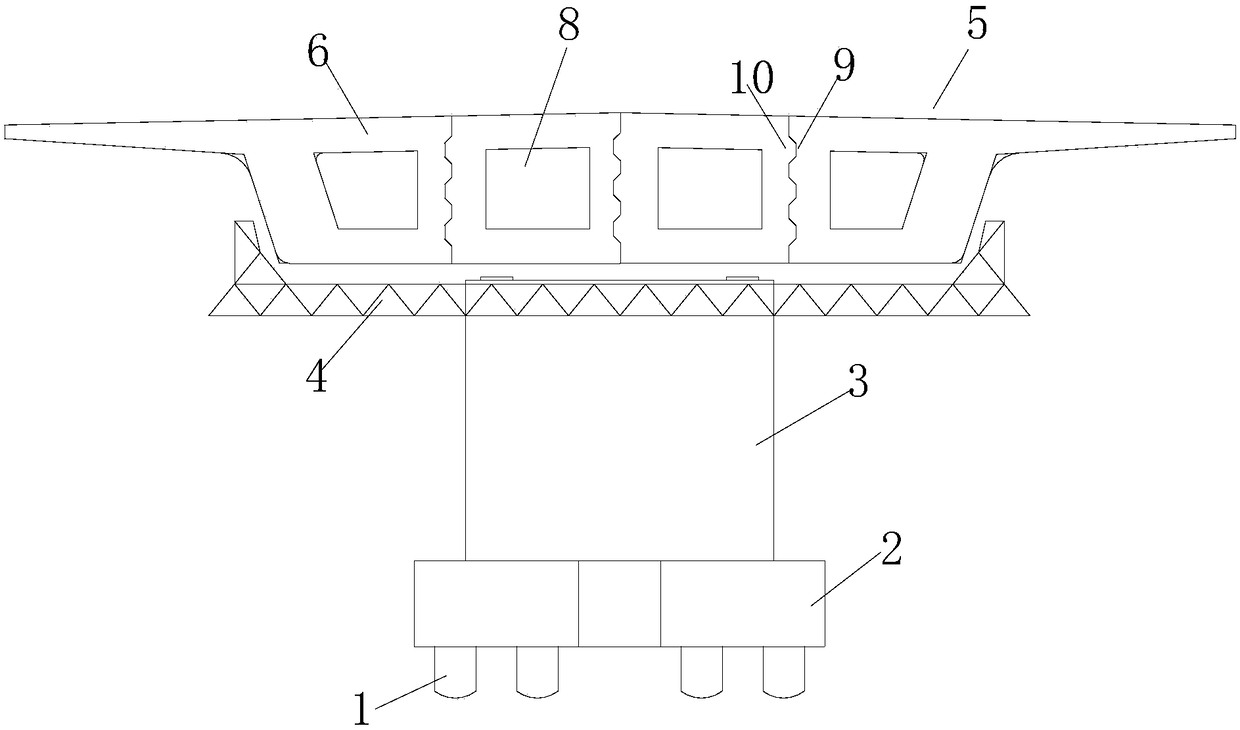

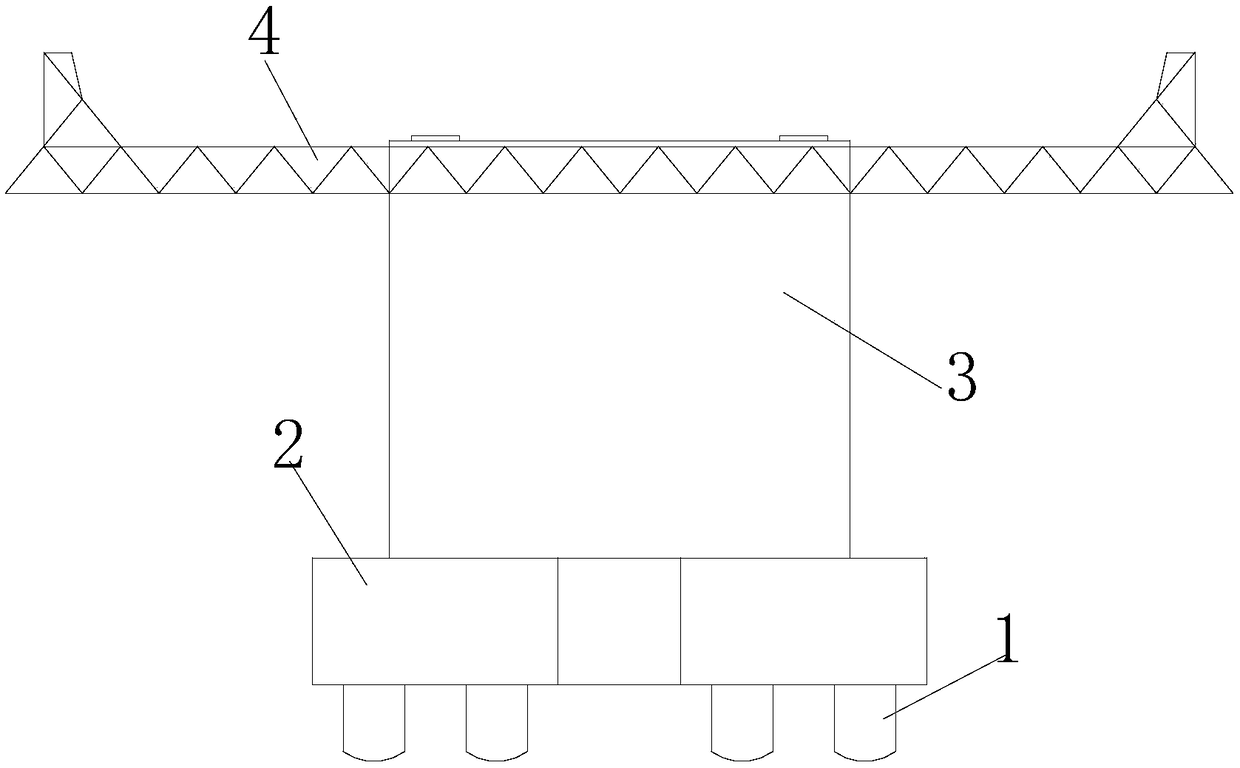

[0030] Such as Figure 1-Figure 3 As shown, this example proposes a precast concrete large box girder with contact surfaces on the web and shear joints, and demonstrates the basic construction steps of the case.

[0031] In this example, the box girder is divided into 4 prefabricated components. Relying on the prefabricated basic components, the prestressed steel bars can be reasonably configured to withstand the loads of hoisting conditions and erection conditions. The contact surface and shear force are set at the web. Holes are reserved in the prefabricated components for transverse prestressing, fine-rolled threaded steel bars, and high-strength bolts, and the prefabricated basic components are prefabricated in the prefabrication factory or on the construction site.

[0032] During the construction process, the construction of relevant pile foundations and bridge piers will be completed first, and temporary construction supports will be erected. Transport the prefabrica...

example 2

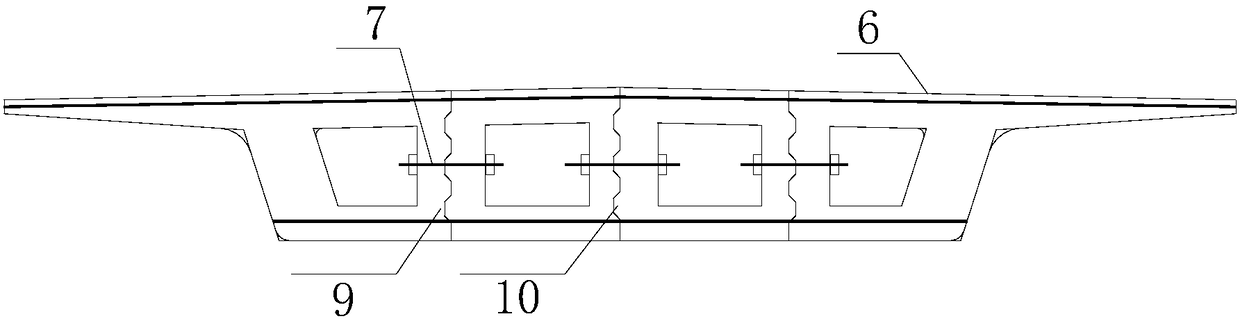

[0034] Such as Figure 4-5 As shown, this example proposes a precast concrete large box girder with a contact surface on the top and bottom plates and a shear bond connection. The construction method is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com