No-cutting-seam cement concrete pavement structure and construction method thereof

A cement concrete and concrete pavement technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of reducing the driving comfort of concrete pavement, wrong platform, mud accumulation, etc., to reduce maintenance and repair costs, ensure integrity, and improve driving The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

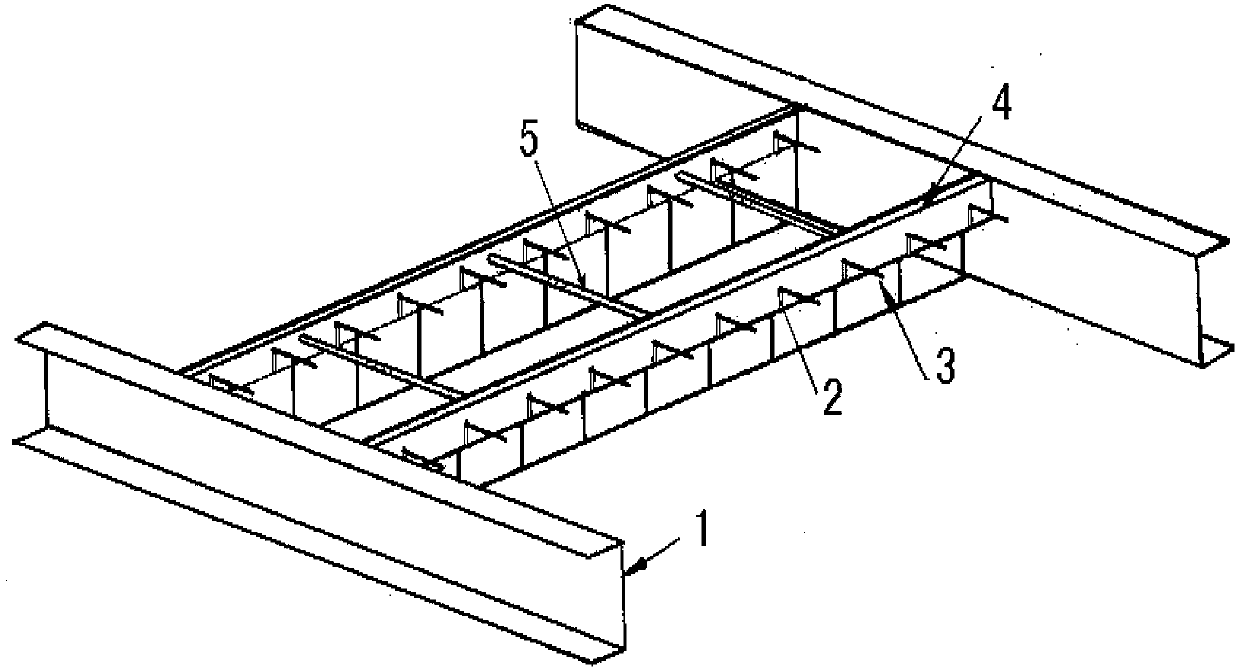

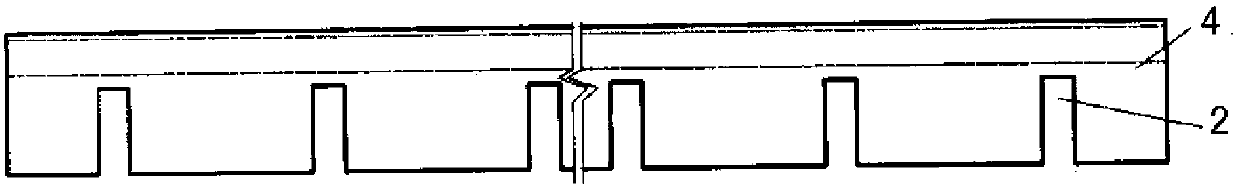

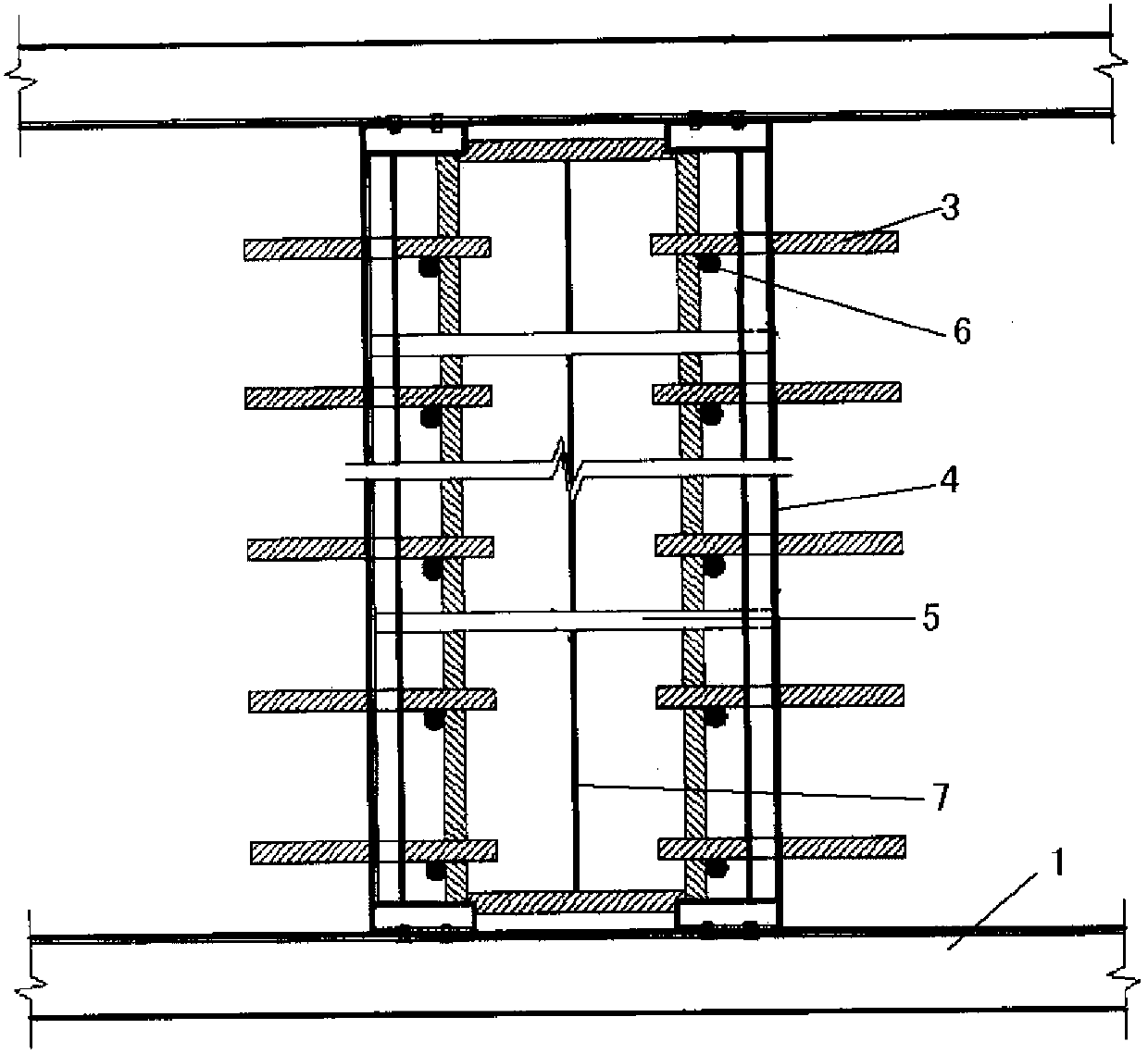

[0026] In this embodiment, the slab of cement concrete pavement 11 is 4m long, 2.85m wide, and 0.28m thick; the high-ductility fiber reinforced cement-based composite material 9 is 0.4m long (generally 10% of the length of the road slab), and 0.1m thick. And arranged along the width direction of the pavement. The strength label of ordinary concrete is C40, and the strength label of high ductility fiber reinforced cement-based composite material is C30, forming a difference in strength. The interface between the two materials is anchored by horizontal anchoring steel bars 3 and vertical anchoring steel bars 6. The horizontal anchoring steel bars are ribbed steel bars with a nominal diameter of 20mm. 7 is fixed on the foundation 12 and arranged along the seam center line. The top of the aluminum plate is 40mm higher than the foundation plane, and above it adopts brackets to arrange dowel bars (not shown in the figure) according to the traditional design. Horizontal anchoring r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com