Rail transit vehicle base in area needing high fill

A rail transit vehicle and high fill technology, applied in the field of rail transit engineering, can solve problems such as huge earthwork, roadbed support engineering and foundation treatment engineering, difficult to control post-construction settlement and construction progress, ecological environment impact, etc. Conducive to soil and water conservation and ecological environmental protection, improve land utilization, reduce construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further described below with reference to the accompanying drawings.

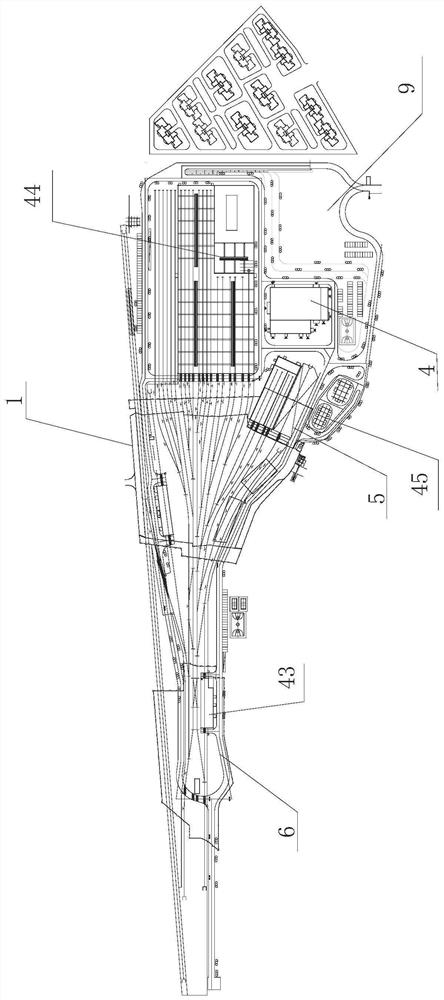

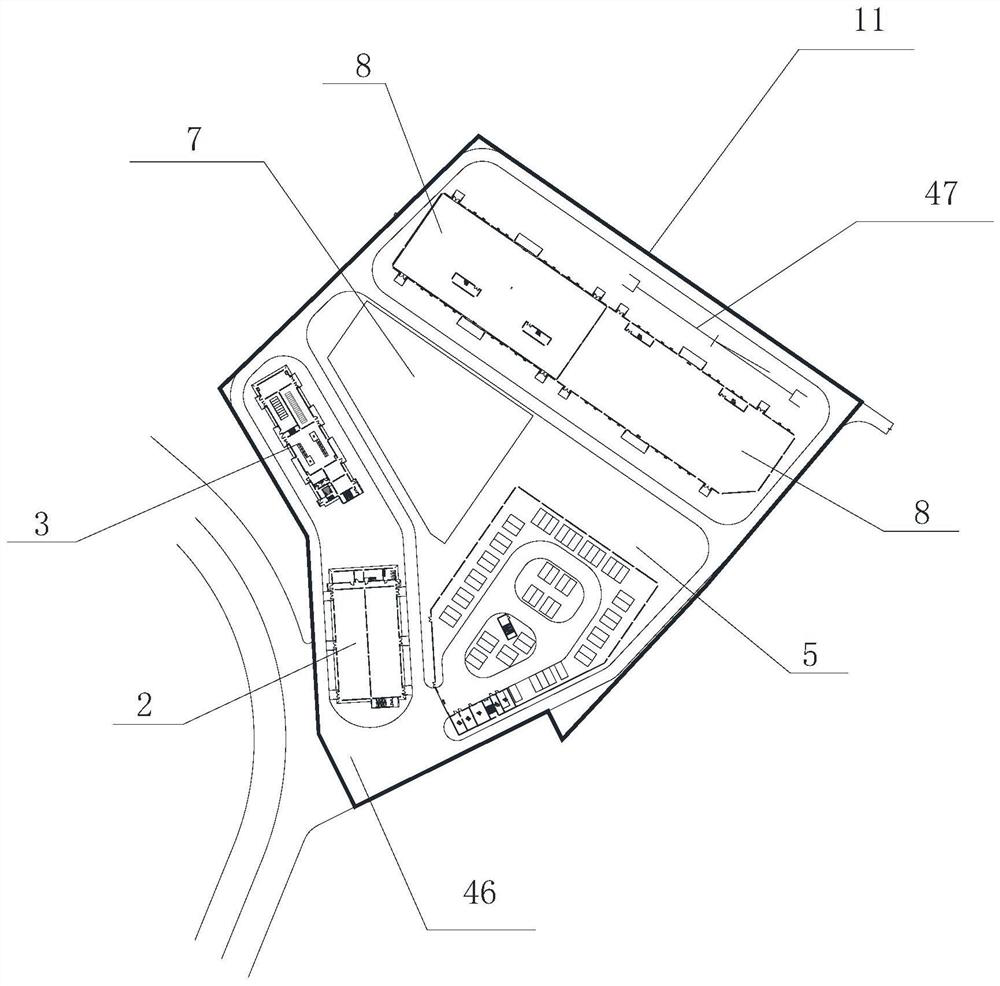

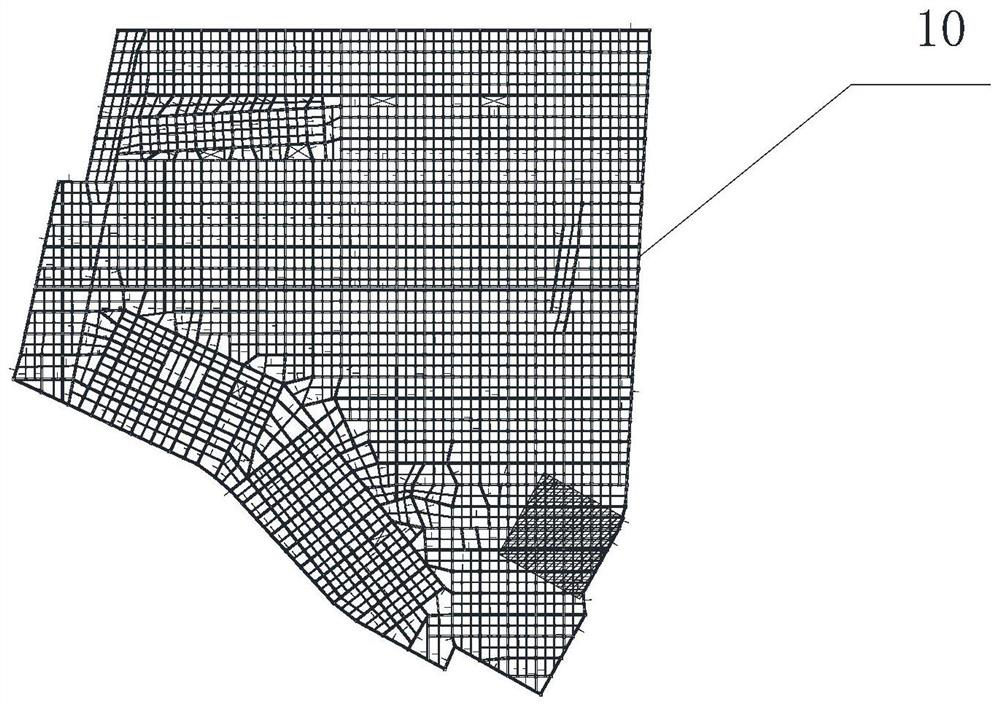

[0039] Referring to the drawings. In this embodiment, the overhead board 1 can be arranged in the hills of the vehicle segment hills and a multilayer concrete frame structure. The overhead plate 1 includes a top plate 10, a sandwich plate 11, and a base layer 12 disposed from top to bottom. Among them, the top plate 10 is provided with a rail-line region structure of a rail transit vehicle base, and a track is provided on the top plate 10, and there is a track warehouse, which can be applied to slag orbital. The rail line structure also has a car washing machine library 43, a round library 6, a comprehensive maintenance workshop 44, a material library 4, a grocery 45, and other production rooms. The frame of the overhead board does not require a large number of filling uniform high, and the field front area of the rail transit vehicle base is based on the mountain natural groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com