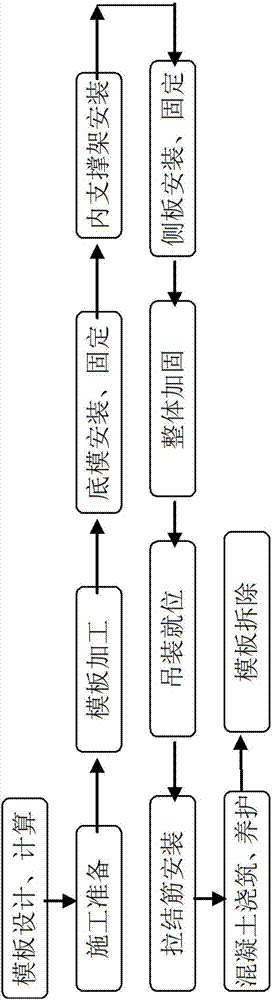

Installation and construction method of high formwork of super high-rise elevator shaft

A technology of tall formwork and elevator shaft, applied in basic structure engineering, construction and other directions, can solve the problems of complex construction process, long construction time, quality defects, etc., and achieve the effect of good promotion value, shortening construction period and saving construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Project overview: An urban rail transit line 7 Sanyang Road wind tower supporting comprehensive development project consists of a tower and podium, with 3 floors underground, 46 floors above ground for the tower, and 7 floors above ground for the podium. The total construction area is 118461m 2 , of which the total floor area above ground is 94295.8m 2 , the total underground construction area is 24165.2m 2 , the building height is 229.1m.

[0041] The thickness of the raft around the core tube in the tower area and the bottom of the elevator shaft is 3.3m, and there are 7 types of raft thickness in the core tube area of the tower: 4m, 4.95m, 6m, 7m, 8m, 9m, and 10m; the elevation of the raft surface in the tower area is -16.3m, and the deepest bottom elevation is -26.3m. There are 14 types of elevation surfaces in the tower area (including elevator shafts, sumps, etc.).

[0042] Dimensions of the elevator shaft (length × width × height): 5600mm × 2500mm × 5700mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com