T structure closure pouring method for mountainous-area high-pier large-span continuous rigid-frame bridge

A rigid frame bridge and closing technology, which is applied in bridges, buildings, bridge construction, etc., can solve problems such as high risk, beam displacement, secondary stress, etc., and achieve the effect of reducing support engineering, large overall rigidity, and good deformation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

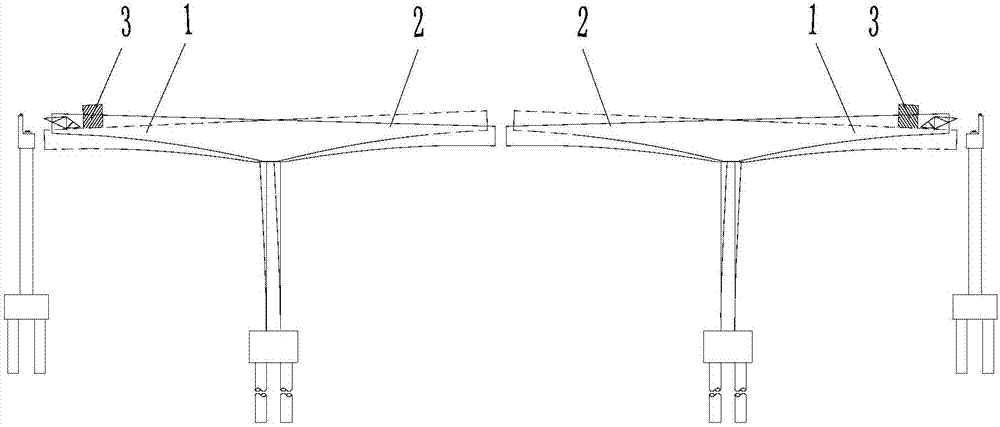

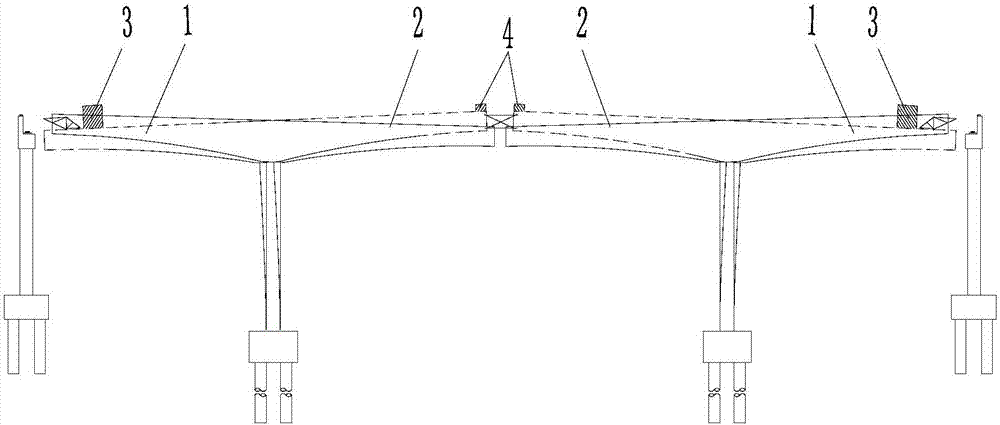

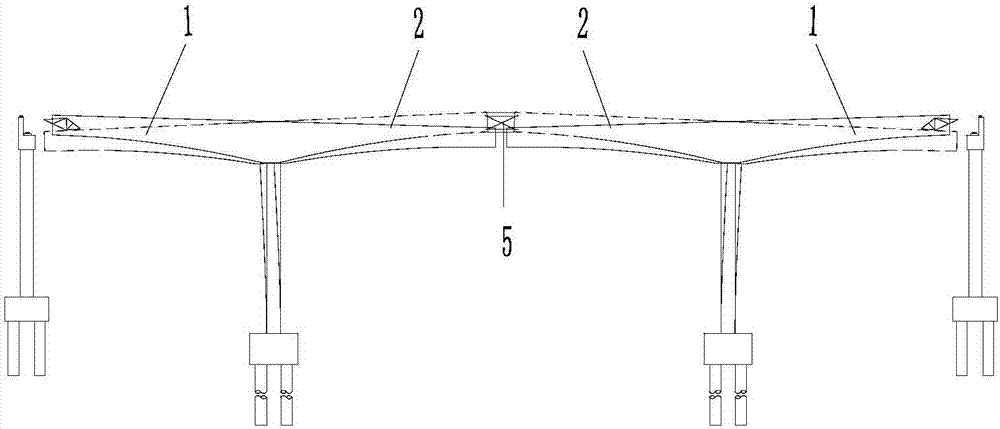

[0022] figure 1 It is a schematic diagram of the T structure of the continuous rigid frame bridge with high pier and long span in mountainous area after loading the ballast body; figure 2 It is a schematic diagram of the T-structure of a long-span continuous rigid-frame bridge with high piers in mountainous areas after loading ballast and counterweight; image 3 It is a schematic diagram of the middle span of the continuous rigid frame bridge with high pier and large span in mountainous area after removing the ballast body and counterweight body; Figure 4 It is a structural schematic diagram of the high-pier and large-span continuous rigid-frame bridge in mountainous area after the middle span and side span are completed, as shown in the figure: the T-structure closing method of the mountainous high-pier and large-span continuous rigid-frame bridge in this embodiment is poured at the T-structure closing Before, the cantilever ends of the T-structure are loaded with ballast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com