Wire planting reinforced brazing connection method for C/C and C/SiC composite materials and metal

A technology of composite materials and connection methods, which is applied in the field of connection between ceramics and ceramic-based composite materials and metals, can solve the problems of poor joint reliability and low joint strength, and achieve reduced stress concentration, high depth/diameter ratio, and reduced residual heat The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

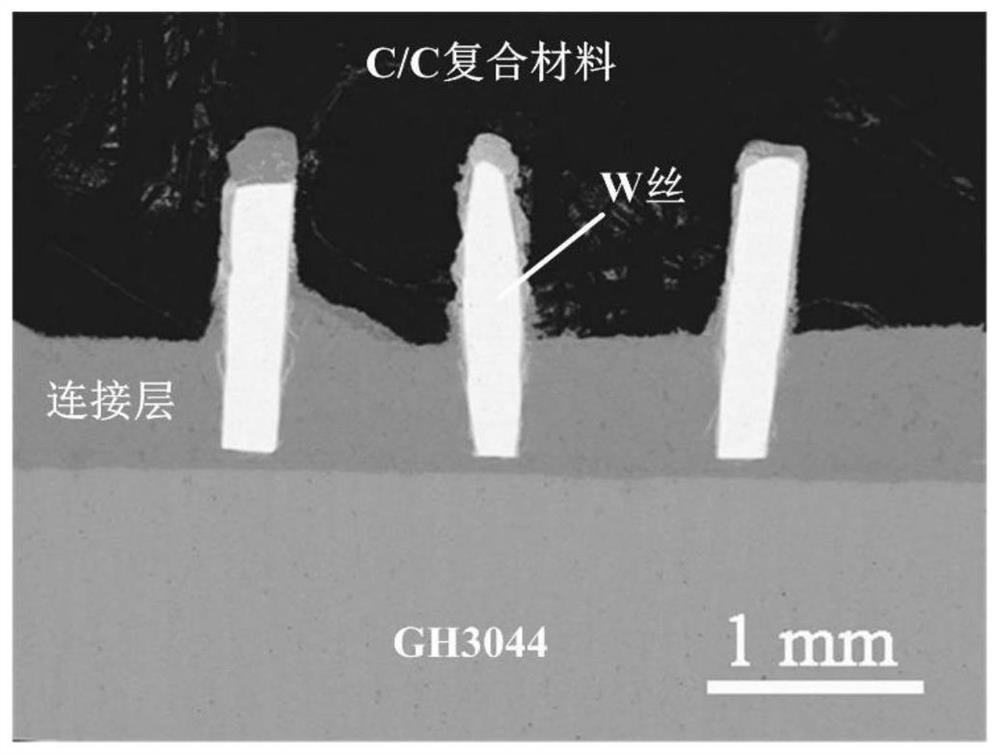

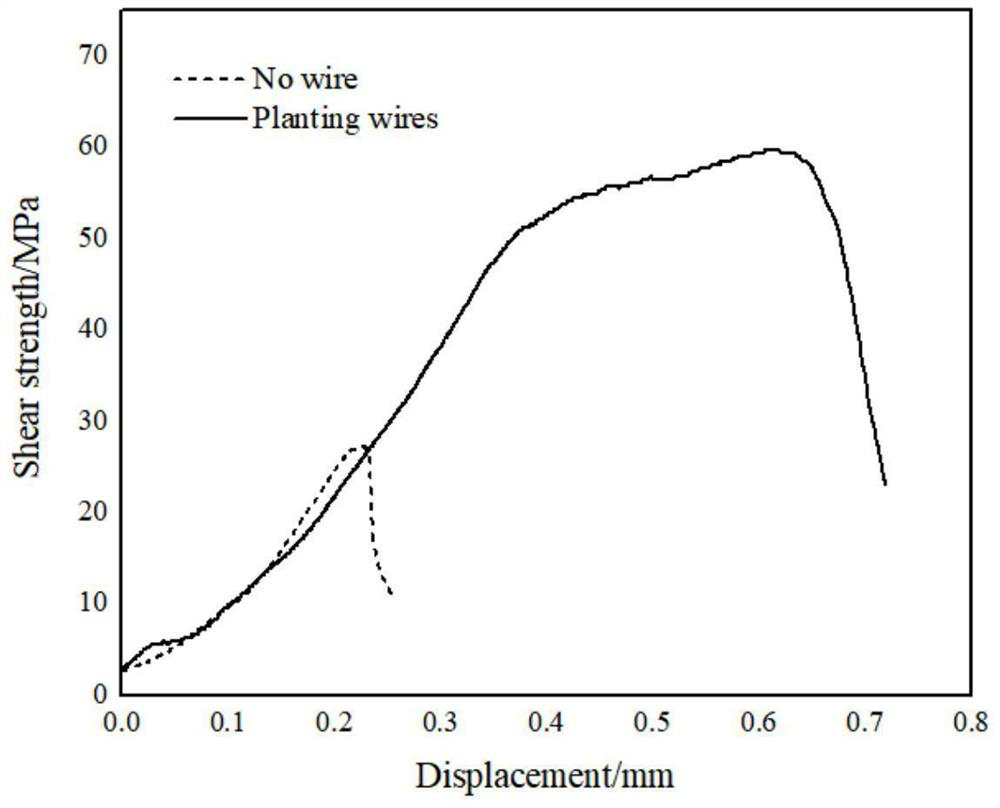

[0024] This embodiment is a tungsten (W) wire-planted brazing method for C / C composite material and GH3044 superalloy.

[0025] The C / C composite material involved is a two-dimensional winding and three-dimensional perforated structure, and its density is 1.65-1.78g / cm 3 , cut into 5×5×5mm 3 The block; the GH3044 superalloy involved is a solid solution strengthened Ni-based superalloy with a density of 8.89g / cm 3 , its melting temperature range is 1352-1375°C, and its thermal expansion coefficient is 16.28×10 -6 K -1 , cut into 10×10×3mm 3 of blocks. The diameter of the W wire involved is 0.3mm, and BNi2 is selected as the solder.

[0026] The specific process of this embodiment includes the following steps:

[0027] Step 1, the composite material is punched. Using the method of electric spark drilling, process some regularly distributed blind holes on the surface of the C / C composite material to be welded, and the punching density (the number of holes per unit area) is...

Embodiment 2

[0035] This embodiment is a molybdenum (Mo) wire-planted brazing method for C / C composite material and GH3044 superalloy.

[0036] The C / C composite material involved is a two-dimensional winding and three-dimensional perforated structure, and its density is 1.65-1.78g / cm 3 , cut into 5×5×5mm 3 The block; the GH3044 superalloy involved is a solid solution strengthened Ni-based superalloy with a density of 8.89g / cm 3 , its melting temperature range is 1352-1375°C, and its thermal expansion coefficient is 16.28×10 -6 K -1 , cut into 10×10×3mm 3 of blocks. The diameter of the Mo wire involved is 0.3mm, and BNi2 is selected as the solder.

[0037] The specific process of this embodiment includes the following steps:

[0038] Step 1, the composite material is punched. Using the method of electric spark drilling, process some regularly distributed blind holes on the surface of the C / C composite material to be welded, and the punching density (the number of holes per unit area...

Embodiment 3

[0046] This embodiment is a method for brazing a C / SiC composite material and a GH4169 superalloy with titanium (Ti) wire reinforcement.

[0047] The C / SiC composite material involved is a three-dimensional braided composite material with a density of 2.0-2.1g / cm 3 , The porosity is 10-15%, the fiber bundle is 3K, the fiber volume fraction is 45-50%, cut into 5×5×5mm 3 square; the GH4169 superalloy involved is cut into 10×10×3mm 3 square, the connecting area is 5×5mm 2 ; The diameter of the Ti wire involved is 0.3mm, and 67.6Ag-26.4Cu-6Ti (mass fraction) is selected as the solder.

[0048] The specific process of this embodiment includes the following steps:

[0049] Step 1, the composite material is punched. Using the method of electric spark drilling, process some regularly distributed blind holes on the surface of C / SiC composite material to be welded, and the punching density (the number of holes per unit area) is 36 holes / cm 2 , the hole depth is 2mm, and the hole di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com