Track varying drilling method and device

A drilling device and trajectory technology, applied in drilling equipment and methods, drilling equipment, directional drilling, etc., can solve the problems of incomplete gas drainage and single drilling form, so as to improve the gas drainage effect and increase the gas consumption. The effect of extraction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

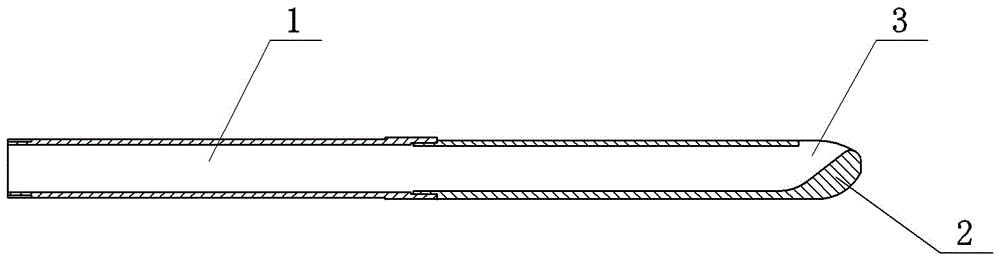

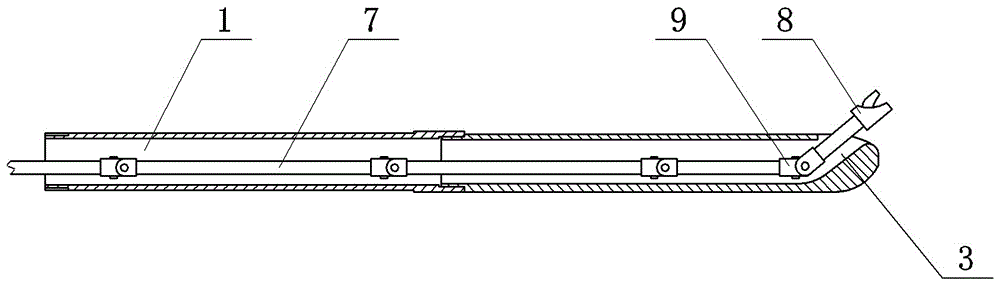

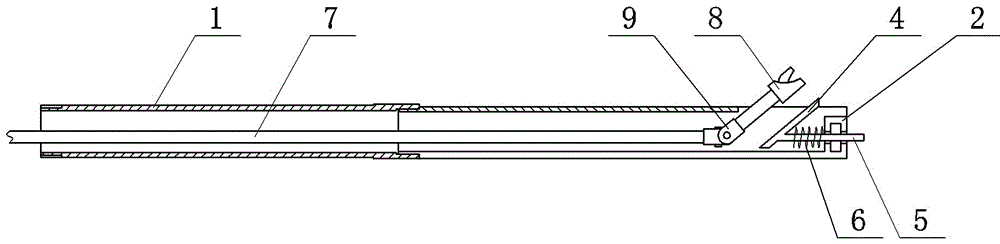

[0019] Embodiment 1: A drilling method with variable trajectory, comprising the following steps: the first step is to drill a 100m deep hole with a diameter of 113mm into the coal seam with a drilling tool, and take out the drilling tool to form a main borehole 10 . The second step is to insert a track-changing drill pipe 1 with a diameter of 89 mm into the main borehole 10. An inclined side port 3 is arranged in front of the track-changing drill pipe 1. The centerline of the inclined side port 3 is aligned with the track-changing drill pipe 1 There is an included angle α on the axis line of , and the included angle α is 45°. In the third step, a bendable anchor cable drill 7 is set inside the track-changing drill pipe 1, and the front end of the anchor cable drill 7 is provided with a drill bit that can swing and can change the drilling trajectory along the inclined guide mechanism; Four steps, according to the different depths of the track-changing drill pipe 1 going deep in...

Embodiment 2

[0021] Embodiment 2: A trajectory-changing drilling device, referring to Fig. 1 and Fig. 2, comprising a trajectory-changing drill pipe 1 and an anchor cable drill 7, an inclined guide mechanism is arranged in front of the orbit-changing drill pipe 1, and the anchor cable drill 7 Set in the track changing drill pipe 1. The drilling rod of the anchor cable drill 7 is that there are many sections of short drill rods connected together by universal joints. The drill rod of the anchor cable drill 7 is provided with a drill bit that can swing, and the drill bit that can swing can change the drill bit along the inclined guide mechanism. into the track.

[0022] The inclined guide mechanism is provided with an inclined side port 3 on the front end side of the track changing drill pipe 1 , and there is an angle α between the center line of the inclined side port 3 and the axis line of the track changing drill pipe 1 . The included angle α ranges from 25° to 60°.

Embodiment 3

[0023] Embodiment 3: On the basis of Embodiment 2, the drilling rod of the cable anchor drill 7 is formed by a rigid hose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com