Novel device capable of increasing coal seam cracks

A coal seam and fissure technology, which is applied in the field of new devices that can increase coal seam fissures, can solve the problems of high pressure and kinetic energy loss, low efficiency of coal bed methane extraction, waste of high-pressure gas from power sources, etc., to reduce air pressure and momentum loss, The effect is good, the effect of increasing the amount of gas extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

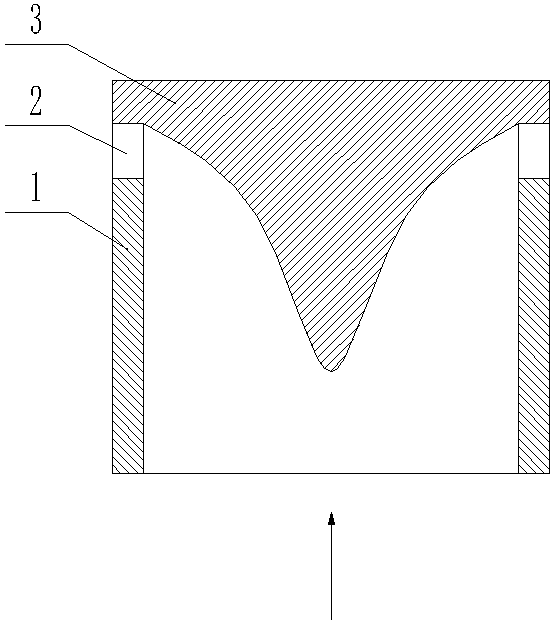

[0012] Such as figure 1 As shown, the present invention is a new type of device capable of increasing coal seam fissures, including an energy relief valve body 1, the top of the chamber of the energy relief valve body 1 is provided with a deflector 3, and the deflector 3 has a parabolic cross section. type rotary body structure, and the deflector 3 is set upside down on the top of the energy relief valve body 1, and the side wall of the energy relief valve body 1 corresponding to the upper part of the deflector 3 is provided with a gas pressure relief port 2, so that the gas entering The high-pressure gas in the cavity of the energy relief valve body 1 is ejected from the gas pressure relief port 2 .

[0013] The deflector 3 is integrally formed with the top plate of the energy relief valve body 1 .

[0014] A gas pressure relief port 2 is symmetrically arranged on the upper side plate of the energy relief valve body 1 .

[0015] The middle part of the deflector 3 has a conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com