Joint gas extraction method combining two-way stereo interlaced hole drilling with collaborative directional long hole drilling

A technology for gas extraction and long drilling, which is applied in gas discharge, earthwork drilling, and fluid extraction, etc., can solve problems such as gas extraction effects affecting medium-thick-thick coal seams, and achieves a small amount of engineering and good stability. , the effect of high extraction concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

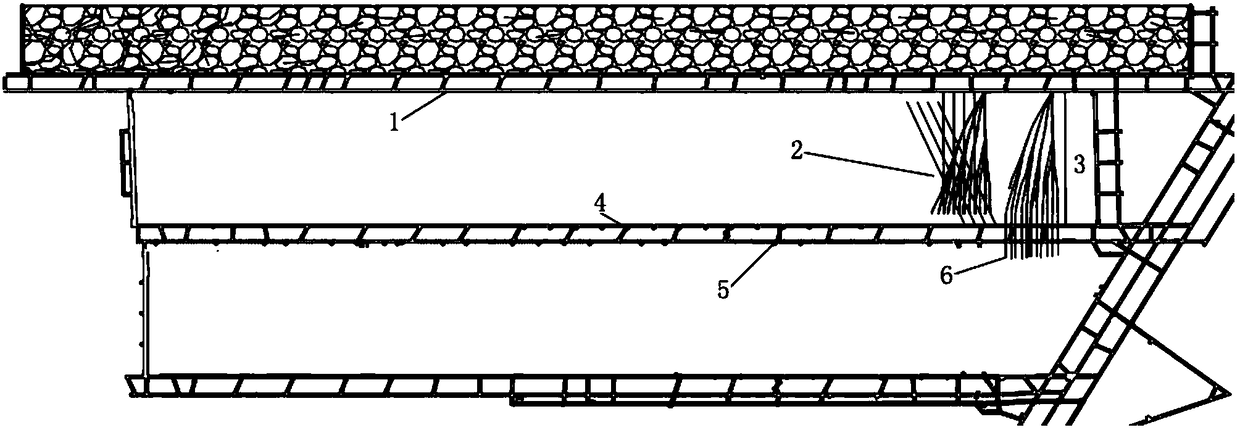

[0018] The invention provides a method for combined gas extraction with two-way three-dimensional staggered drilling and directional long drilling, such as figure 1 As shown in , where 1 represents the track trough of the mining face, 2 represents the coal mine underground two-way three-dimensional staggered drilling and long-distance directional drilling combined gas drainage, 3 represents the production stop line, 4 represents the transportation trough of the mining face, and 5 represents The track along the trough of the standby mining face, 6 indicates that the long-distance directional drilling is pre-extracted in advance and the mining face is transported along the trough and the track of the standby mining face is along the trough coal body. The method of the present invention includes the following steps,

[0019] a. During the road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com