Coal seam gas extraction method based on U-shaped well and directional drilling

A technology for directional drilling and coal seam gas, which is applied in the directions of gas discharge, earthwork drilling, mining equipment, etc. The effect of good mining effect, simple construction and large extraction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] A method for progressively extracting coal seam gas based on U-shaped well and directional drilling, comprising the following steps:

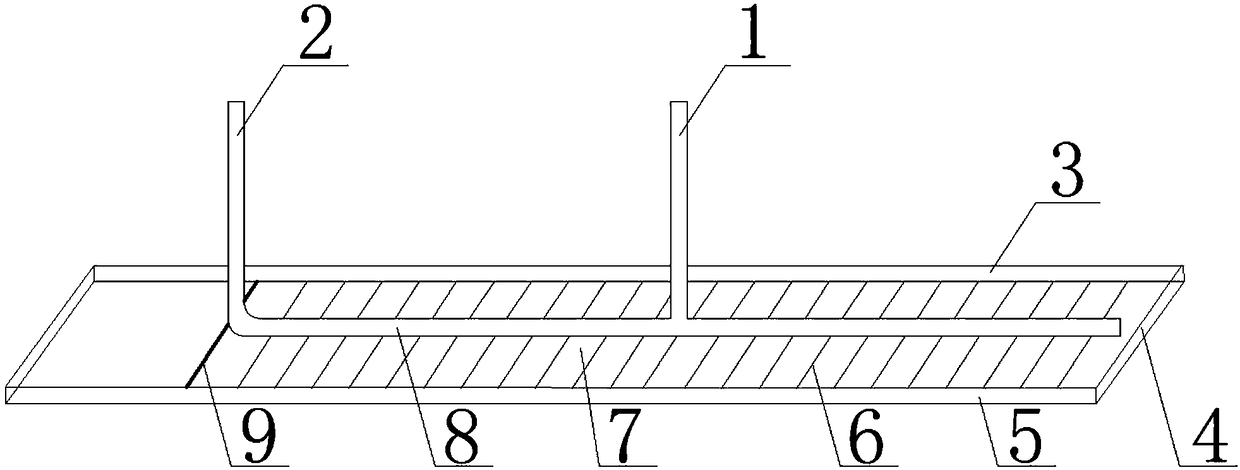

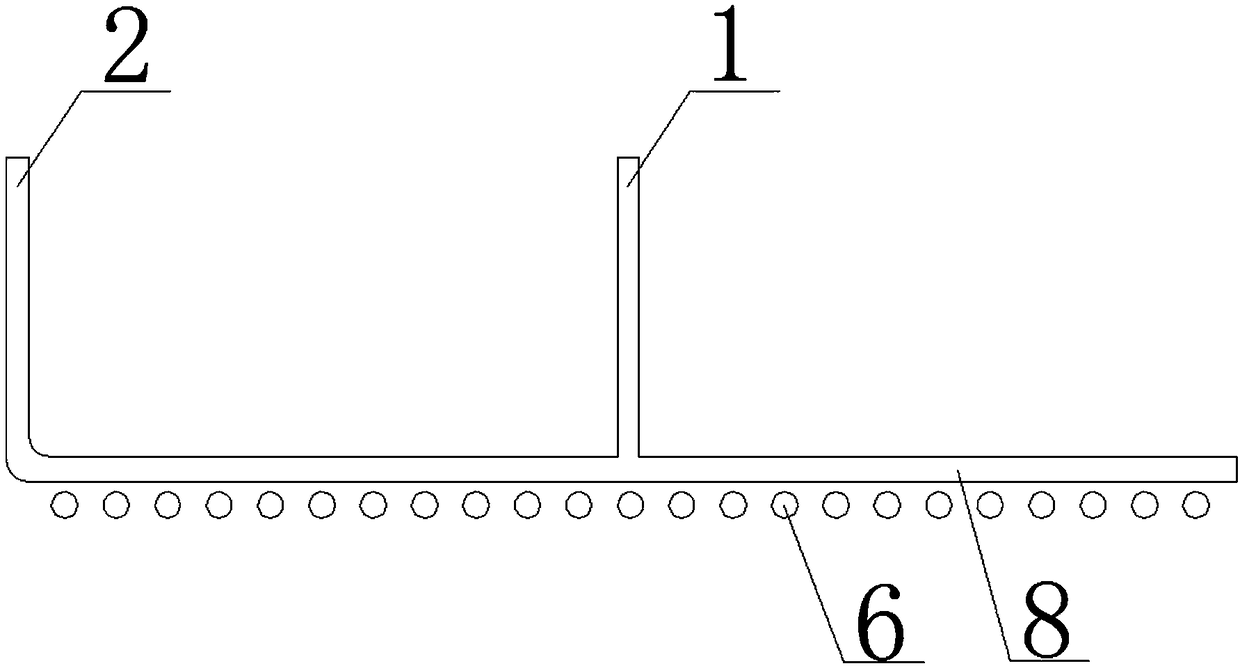

[0023] 1) Planning the scope of the mining area, planning the positions of the mining face 7, the stop line 9, the transport trough 5, the return air trough 3, and the cutting hole 4;

[0024] 2) In the middle of the mining face 7, between the transportation chute 5 and the return air chute 3, and near the return air chute 3, drill vertically down to the coal seam to form a No. Ground drilling 1, through the No. 1 ground drilling 1, large-area pre-pumping of coal seam gas is carried out;

[0025] 3) After the gas production of the No. 1 ground well 1 enters the attenuation period, drill vertically down to the coal seam near the stop line 9 and close to the return air trough 3 to form the No. 2 ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com