Nitrogen case hardening method of orientation silicon steel

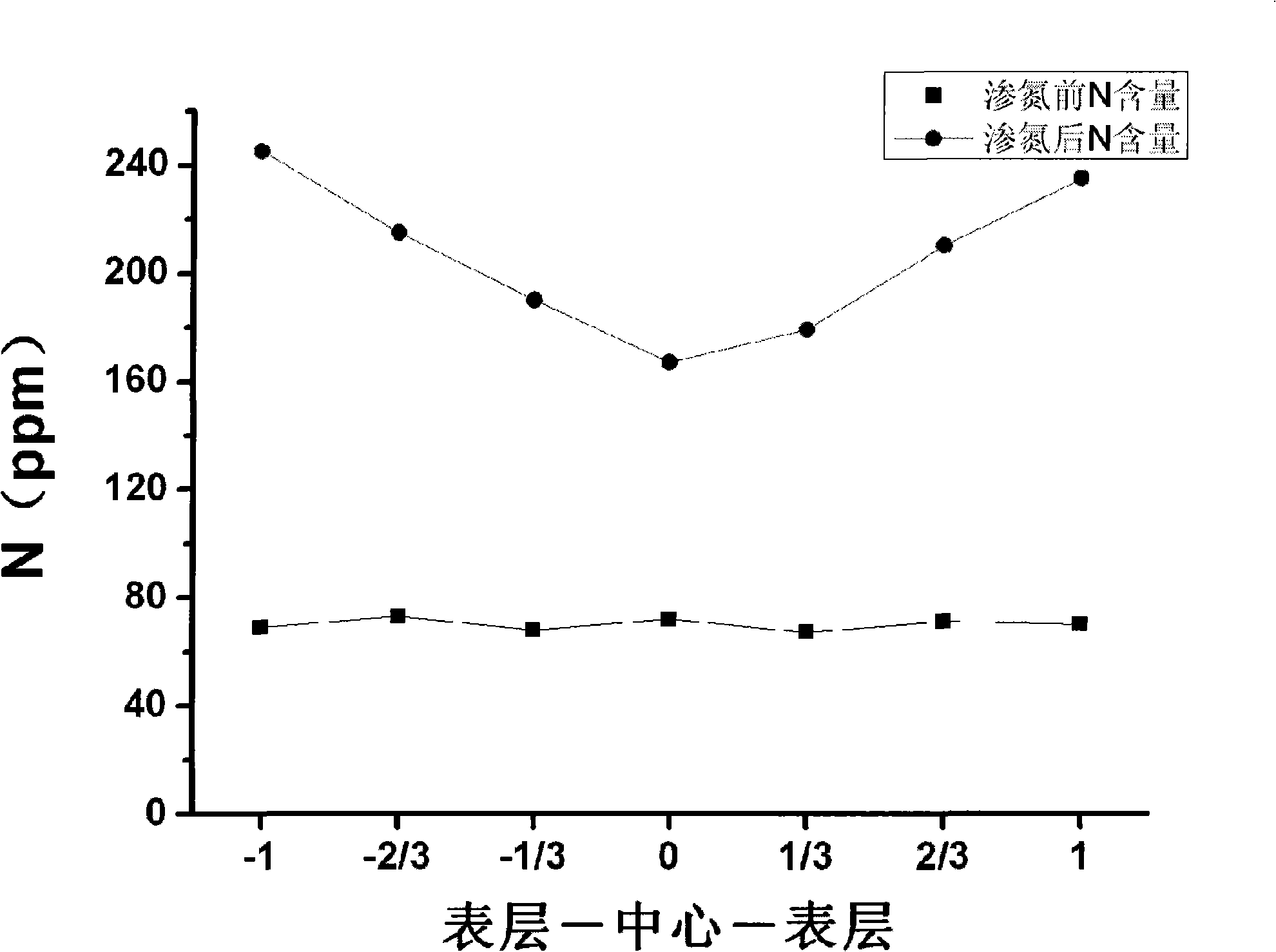

A technology of oriented silicon steel and nitriding, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of uneven surface distribution, unstable finished product performance, unstable N content, etc., and achieve simplified surface Quality control, improvement of process stability, easy and sufficient solid solution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Nitriding is carried out on steel with multiple components, the components are shown in Table 1:

[0038] Table 1

[0039] No.

Si (%)

C

(ppm)

Mn(%)

S

(ppm)

Al 可溶

(ppm)

N

(ppm)

Ti

(ppm)

1

2.80

420

0.15

65

150

80

11

2

2.80

550

0.15

65

200

80

12

3

3.10

420

0.15

75

270

70

10

4

3.10

540

0.13

65

310

70

11

5

3.40

420

0.14

70

400

69

10

[0040]Slabs of each of the above compositions were heated to 1200°C for 180 minutes. Then directly hot rolled to 2.3mm. The hot-rolled steel strip is annealed in two steps, first heated to 1130°C, and then lowered to 900°C in 200 seconds during the cooling process. Subsequently, the steel plate was quenched in water at 100°C. After...

Embodiment 2

[0047] After the steel strip of composition 3 is processed to decarburization by the process in embodiment 1, adopt 90% N 2 +5%H 2 +2% NH 3 With different plasma nitriding processes, the corresponding N infiltration amount and magnetic properties obtained are shown in Table 3:

[0048] table 3

[0049] no

Embodiment 3

[0051] After the steel strip of composition 3 is processed to decarburization by the process in embodiment 1, the following nitriding parameters are fixed: 600° C. of nitriding temperature, and the atmosphere composition is 90% N 2 +5%H 2 +2% NH 3 , The vacuum degree is 1500Pa, and the bias voltage is 850V. Control the nitriding time at 0-50s, and the relationship diagram of "nitriding amount - nitriding time" obtained is shown in Table 4: Table 4

[0052] Example and pair

Proportion

Nitriding time

(s)

Nitriding amount

(ppm)

Inhibitor Average

Size (nm)

B 8 (T)

comparative example

5

60

13

1.82

comparative example

40

190

67

1.87

comparative example

50

210

80

1.83

Example

10

90

20

1.93

Example

20

130

25

1.95

Example

30

160

43

1.92

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com