A production method of thin-gauge low-temperature high-magnetic-induction grain-oriented silicon steel strip

A technology of high magnetic induction orientation and production method, applied in the field of oriented silicon steel production, can solve the problems of easy fluctuation and poor performance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

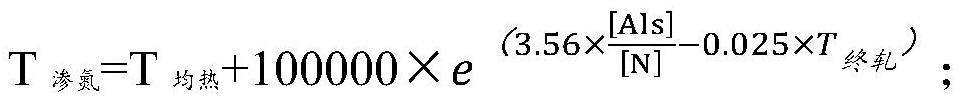

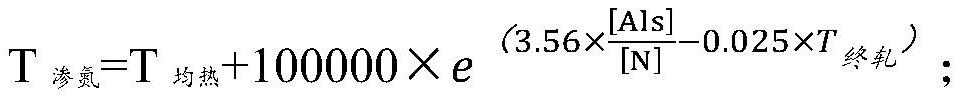

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for producing thin-gauge, low-temperature, high-magnetic-induction grain-oriented silicon steel strip, the steps of which include:

[0049] (1) Steelmaking and continuous casting to produce slabs, the superheat of molten steel is 20°C, and the equiaxed crystal ratio is controlled by electromagnetic stirring in the secondary cooling area to 20%; the equiaxed crystal ratio refers to the percentage of equiaxed crystals in all crystals ;

[0050] The cast slab composition is: C: 0.07%; Si: 3.01%; Mn: 0.10%; S: 0.010%; Als: 0.0230%; N: 0.0090%; Sn: 0.05%; Cu: 0.3%; the rest is Fe and unavoidable impurity elements;

[0051] (2) Heating the cast slab at a heating temperature of 1200°C, followed by rough rolling and finish rolling, the edge heater is used at the entrance of finish rolling, the final rolling temperature is 900°C, and the thickness of the hot-rolled plate is 1.5-3.5mm;

[0052] (3) Adopt two-stage normalization, dry nitrogen at...

Embodiment 2-12

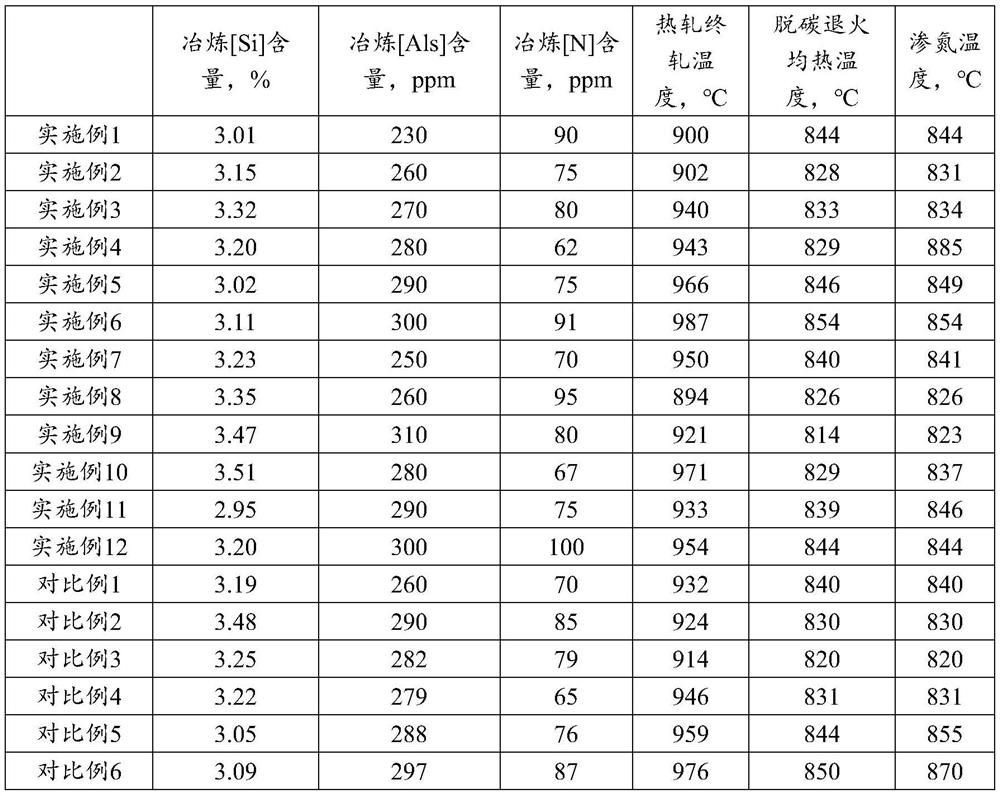

[0073] Embodiments 2-12 respectively provide a thin-gauge low-temperature high-magnetic induction grain-oriented silicon steel strip production method, the steps of which are basically the same as in Embodiment 1, the difference is that the chemical components of the slab are different in Si, Als, and N content, and the hot-rolled Final rolling temperature, decarburization annealing soaking temperature, nitriding temperature. All the other processing conditions and operation are consistent with embodiment 1. The main process conditions of Example 2-12 are shown in Table 1, and the magnetic properties, edge line crystals and plate shape of the high magnetic induction grain-oriented silicon steel obtained in Example 2-12 are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com