Induction heating nitriding method for oriented silicon steel

A technology of induction heating and oriented silicon steel, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of unfavorable promotion of oriented silicon steel manufacturing enterprises, high requirements for equipment and production operation, and achieve convenient implementation and heating Fast, evenly distributed results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

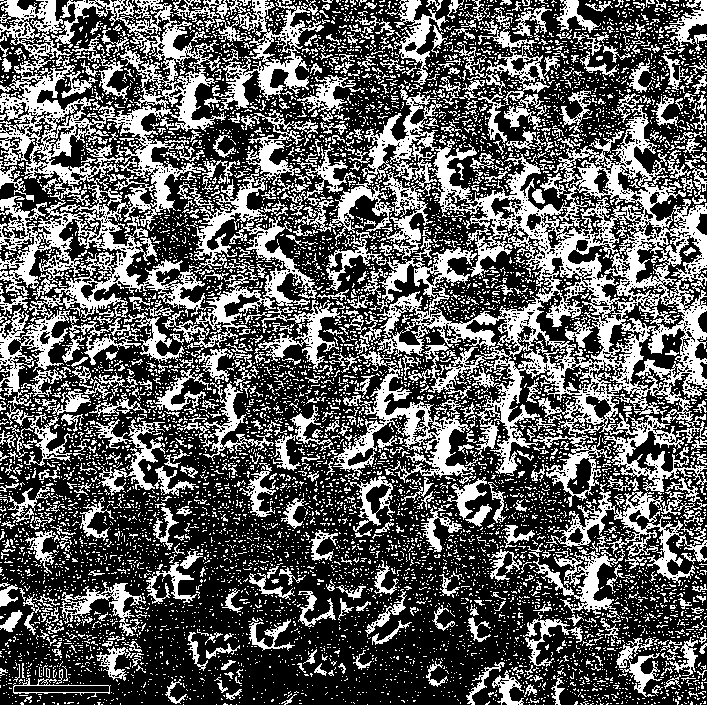

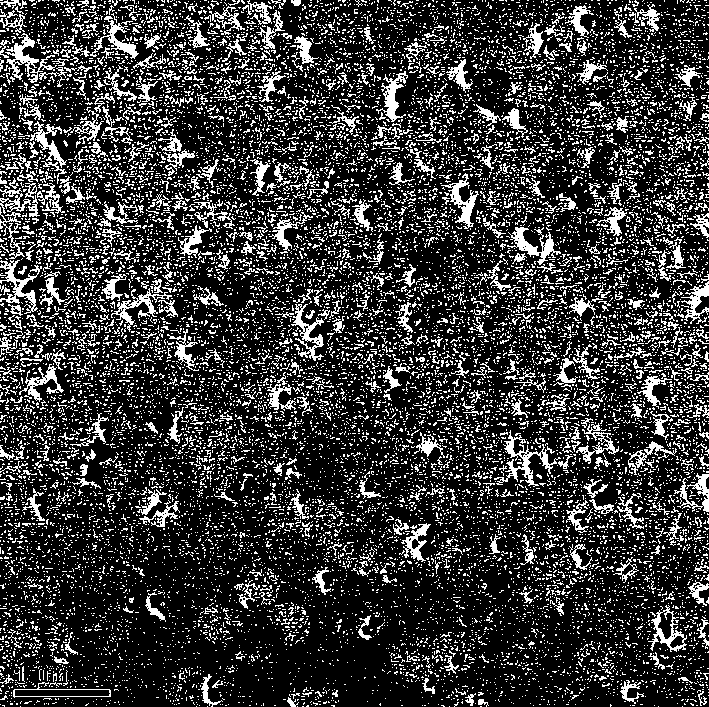

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments.

[0023] Table 1 is a list of specific parameters and performance test results of the nitriding process in various embodiments of the present invention.

[0024] Explanation: the compositions of the following embodiments of the present invention are all arbitrarily selected in the following ranges:

[0025] The chemical composition and weight percentage are: Si: 2.95~3.15%; C: 0.048~0.068%; Mn: 0.06~0.12%; S: 0.080~0.012%; Als: 0.0205~0.0255%; N: 0.008~0.010%; Cu: 0.010~0.015%; Cr: 0.08~0.10%; P: 0.08~0.010%; the balance Fe and unavoidable impurities.

[0026] Each embodiment of the present invention is carried out according to the following steps:

[0027] 1) After smelting and continuous casting; heating the slab to 1100-1250°C for hot rolling, normalization, cold rolling and decarburization;

[0028] 2) Carry out two-stage nitriding treatment in the induction nitridin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com