Middle frame manufacturing method and middle frame structure

A manufacturing method and frame structure technology, applied to electrical components, casings/cabinets/drawer components, household components, etc., can solve the problems of waste of raw materials, high processing costs, and long processing cycles, etc., and achieve reduction The difficulty of processing, the simplification of processing steps, and the effect of saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

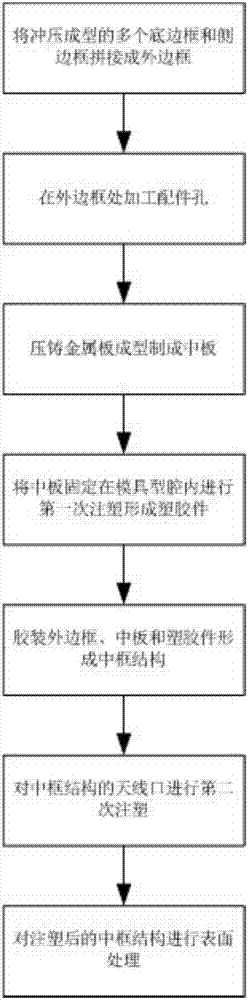

[0047] Such as figure 1 Shown is a flow chart of a method for manufacturing a middle frame, and the method includes the following steps:

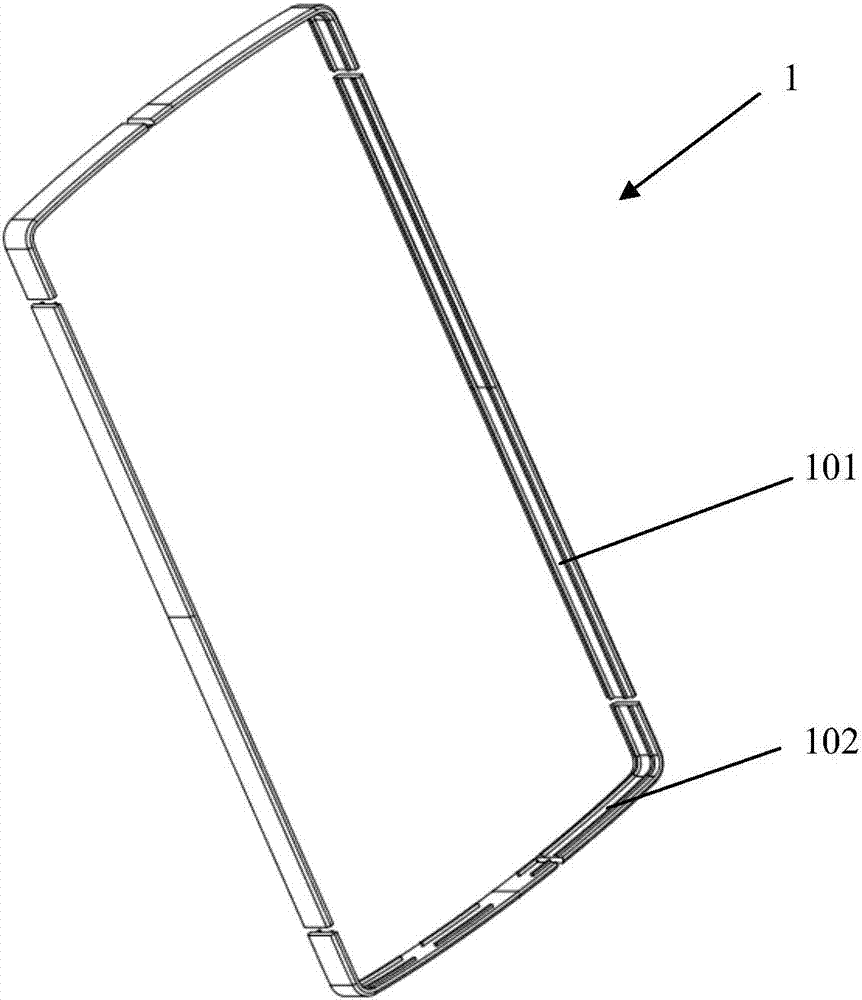

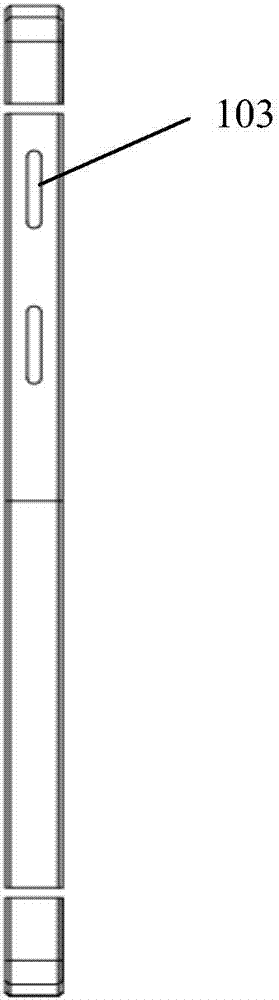

[0048] Step 1: Select metal profiles. Stainless steel is preferred for metal profiles. Stainless steel has corrosion resistance and is not easily corroded by air, steam or water. In addition to corrosion resistance, stainless steel also has high temperature and low temperature resistance. Such as figure 2 As shown, a plurality of side frames 101 and a plurality of bottom frames 102 formed by stamping metal profiles are spliced into an outer frame 1. In this embodiment, the number of side frames 101 is four, and the number of bottom frames 102 is four. The four bottom frames 102 are spliced to form the bottom edge of the outer frame 1, the bottom edge of the outer frame 1 is U-shaped, and the outer frame 1 spliced by the four bottom frames 102 and the four side frames 101 is generally rectangular; Figure 6 As shown, the side frame ...

Embodiment 2

[0057] Such as Figure 2-11 The middle frame structure manufactured by the above middle frame manufacturing method is shown, and the middle frame structure includes:

[0058] The outer frame 1 is spliced by a plurality of bottom frames 102 and a plurality of side frames 101. In this embodiment, the number of side frames 101 is four, the number of bottom frames 102 is four, and the number of four bottom frames The bottom edge of the outer frame 1 is spliced by the frame 102, and the bottom edge of the outer frame 1 is U-shaped, and the outer frame 1 spliced by the four bottom frames 102 and the four side frames 101 is generally rectangular; as Figure 6 As shown, the side frame 101 is in the shape of a line as a whole, and it includes a third bottom plate 1011 and two third vertical plates 1012. The third bottom plate 1011 is vertically provided with two third vertical plates 1012, and the two third vertical plates 1012 Parallel to each other and the length extension dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com