Electric brush plating equipment for flat metal parts and brush plating method

A technology for parts and brush plating, applied in jewelry and other directions, can solve the problems of relying on manual operation, low work efficiency, and unstable coating quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

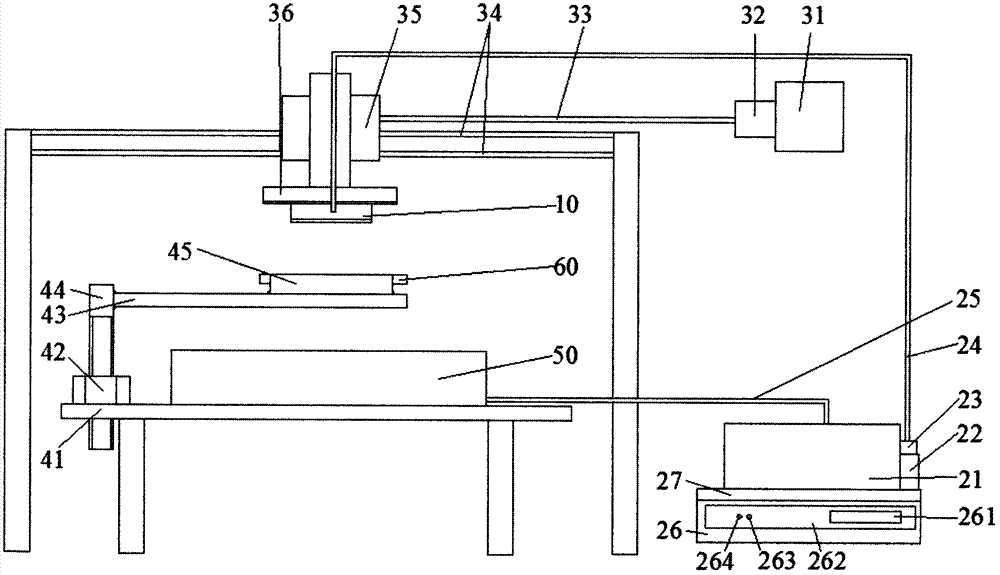

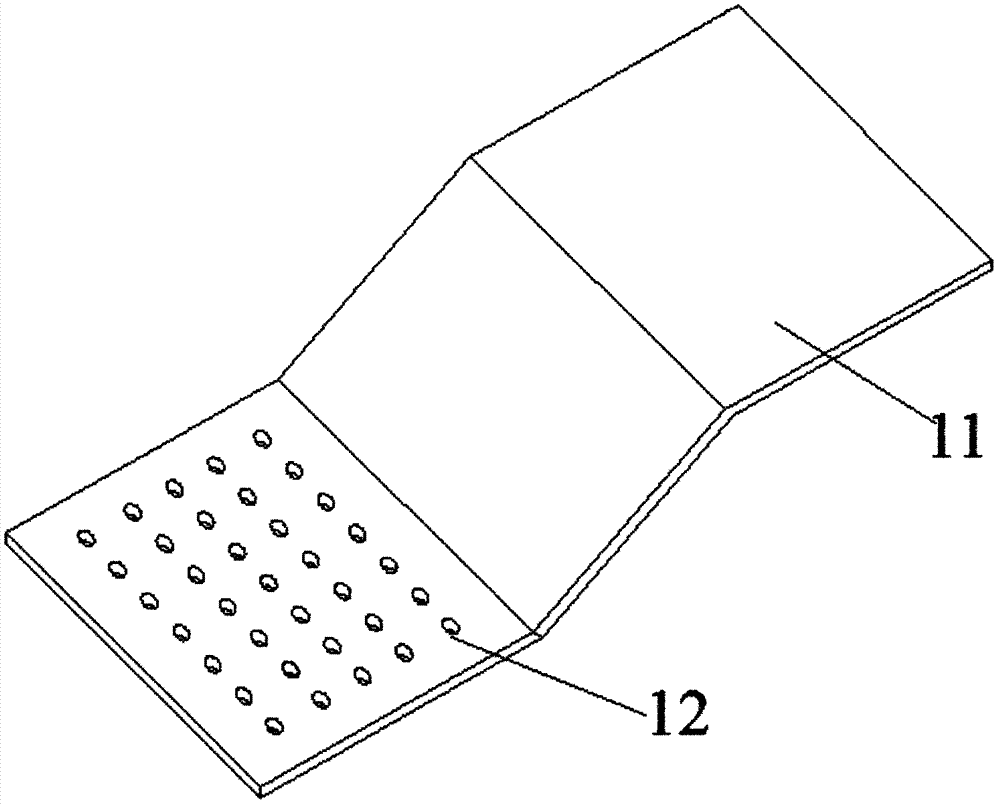

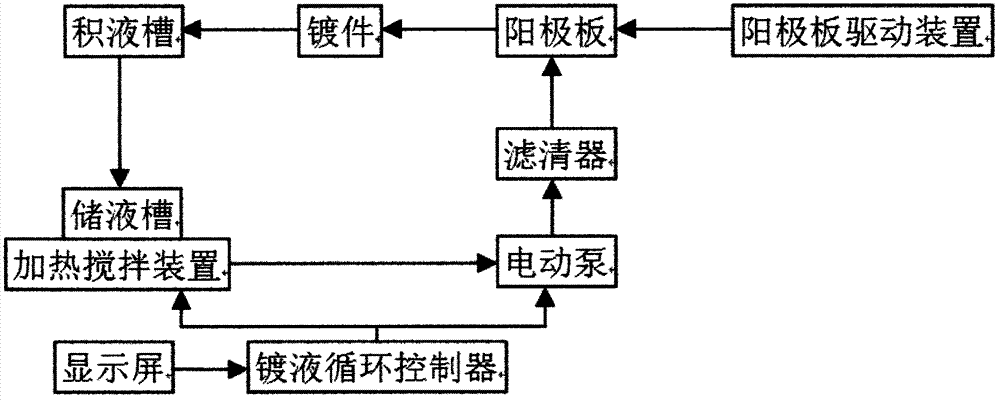

[0028] refer to Figure 1~3 , an embodiment of the present invention is a brush plating equipment for flat metal parts, mainly comprising:

[0029] The plated piece clamping device, the plated piece clamping device includes the liquid accumulation tank platform 41 for placing the liquid accumulation tank, the screw rod 44, the nut 42 connecting the liquid accumulation tank platform 41 and the screw rod 44, connected with the screw rod 44 The plated piece holding frame 43, and the plated piece clip 45 for holding the plated piece 60 fixed on the plated piece holding frame 43;

[0030] An anode plate driving device, the anode plate driving device includes a speed-regulating motor 31 for output power, a transmission mechanism 32 connected to the output shaft of the speed-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com