Steel checkerboard pressure welding machine

A pressure welding machine and steel grating technology, applied in welding power sources, welding equipment, resistance welding equipment, etc., can solve the problems of high failure rate, inability to produce large-sized steel gratings, and poor welding appearance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

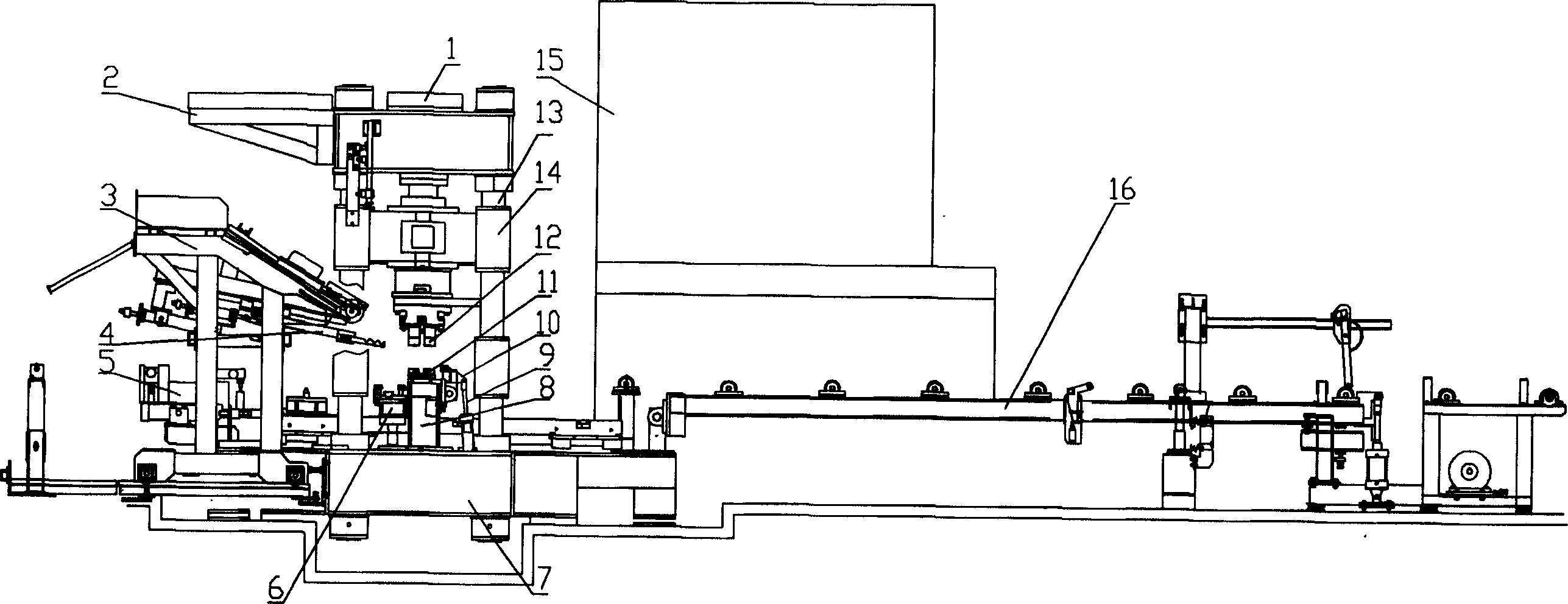

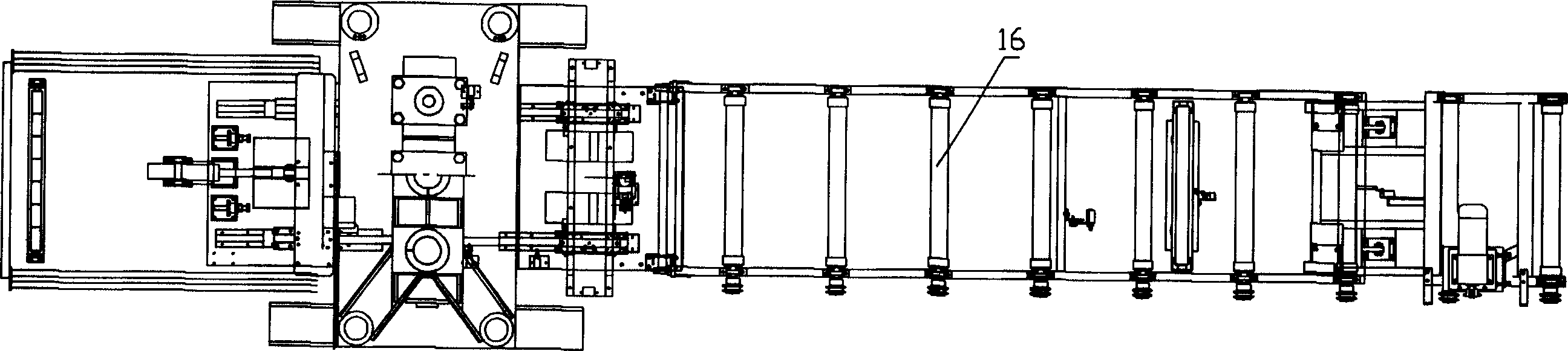

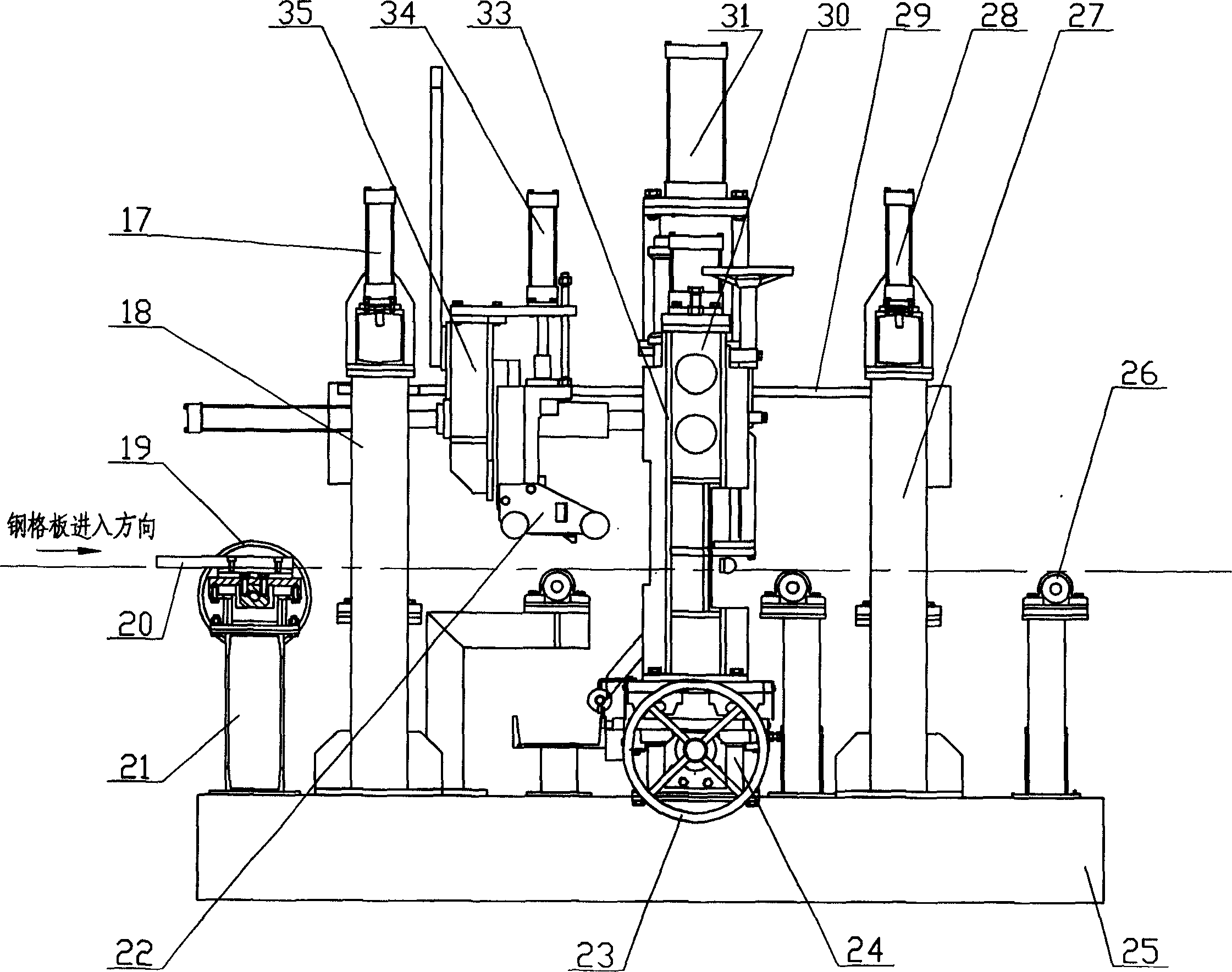

[0013] The present invention is made up of pressure welding machine 2, intermediate feeding roller table 16 and head cutting machine. Such as figure 1 , 2 As shown, a flat steel stepping trolley 5 and a flat steel fixture 6 are seated below the front end of the pressure welding machine base 7, and a twisted steel feeding trolley 3 and a twisted steel lifting mechanism 4 are fixed above the flat steel stepping trolley 5. The disc automatic positioning device can ensure the stepping accuracy of the flat steel. Fix the pallet 8 on the pressure welding machine base 7 at the rear end of the flat steel fixture 6, fix the receiving platform 11 on the pallet 8, and hinge through the four connecting rods 9 on the pressure welding machine base 7 close to the rear end of the receiving platform 11 , The flush baffle plate 10 controlled by the hydraulic cylinder. Above the receiving platform 11 is the positive and negative electrode row 12, the positive and negative electrode row 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com