Punching method and dedicated die for serialization porous complex inserting metal piece

A technology for inserting metal parts and metal parts, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem of poor consistency of the size and shape error of the parts, which affects the precision of the parts and the life, quality and forming accuracy of the mold Difficult to guarantee and other problems, to achieve the effects of less stress concentration, less uneven deformation, and improved working conditions of the mold

Active Publication Date: 2013-01-02

南通集智知识产权服务有限公司

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Purpose of the invention: The present invention provides a stamping method and a special die for serialized porous and complex metal parts. The accuracy is difficult to guarantee, the process is long, the efficiency is low, the cost is high, and it is easy to cause stress concentration in some parts of the part, which will affect the precision of the part and the problem of low mold life.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

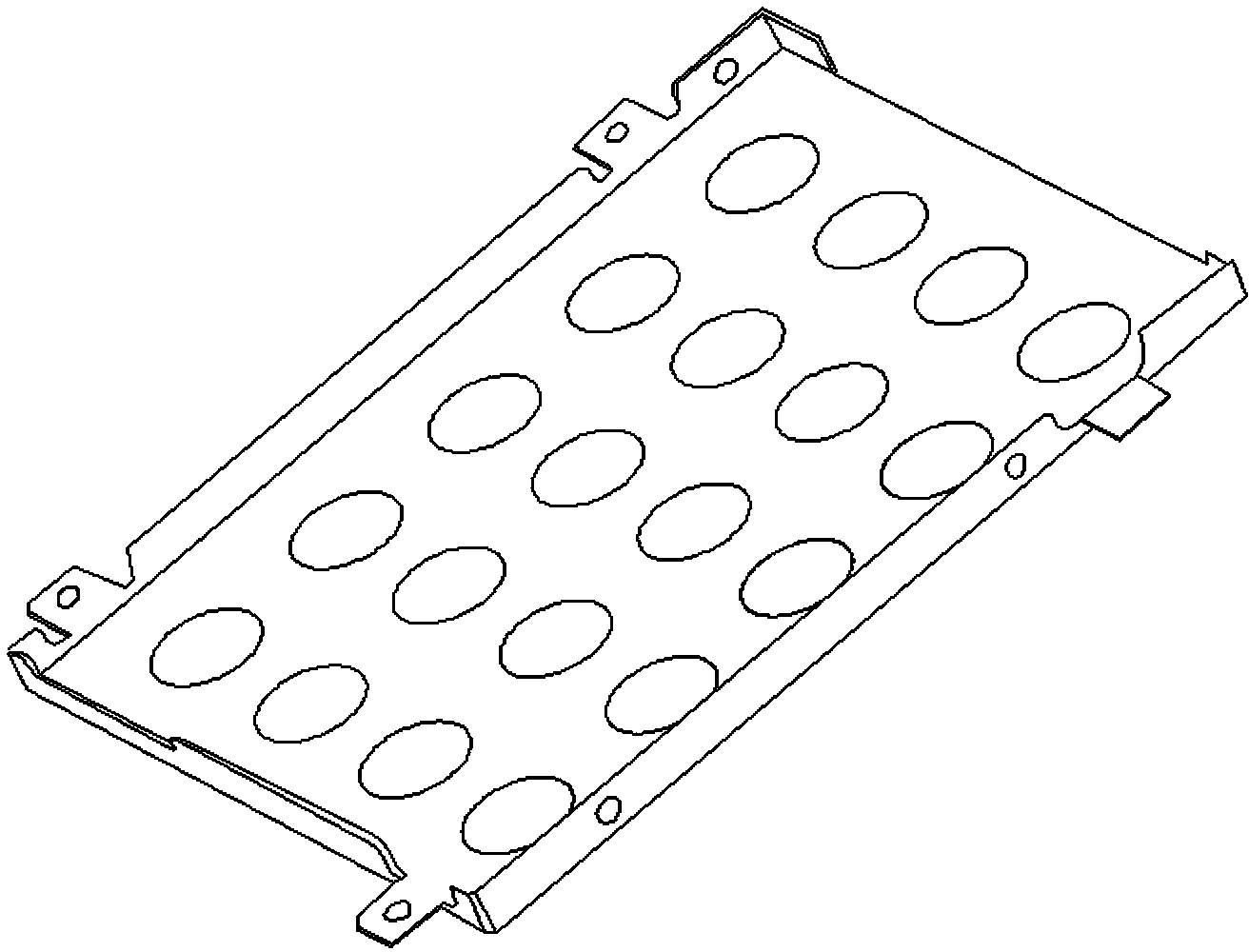

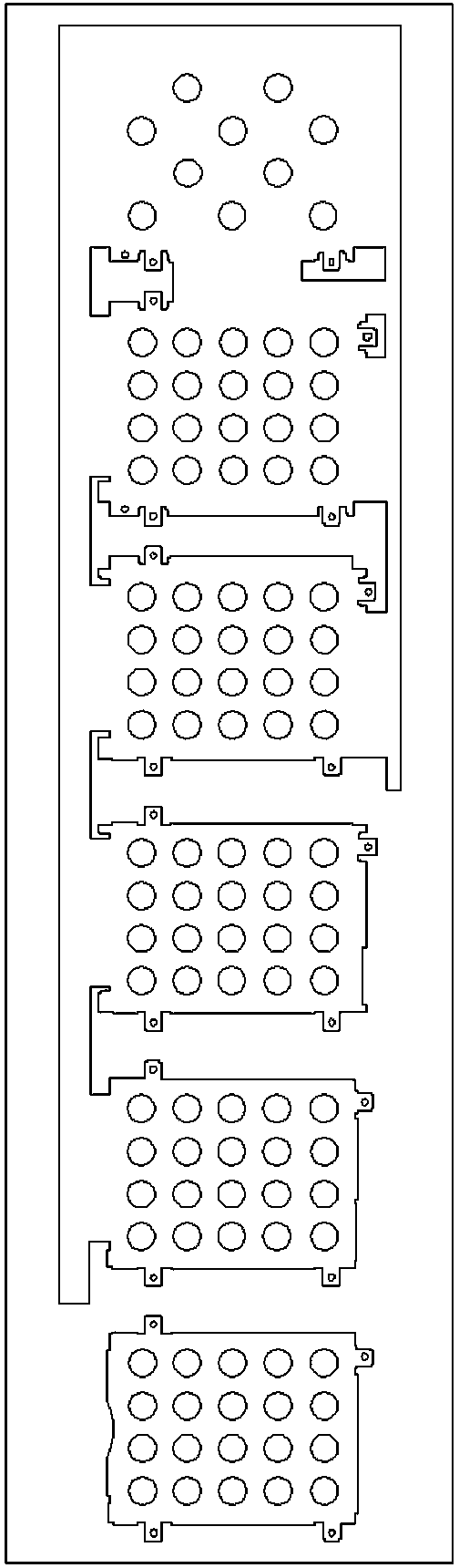

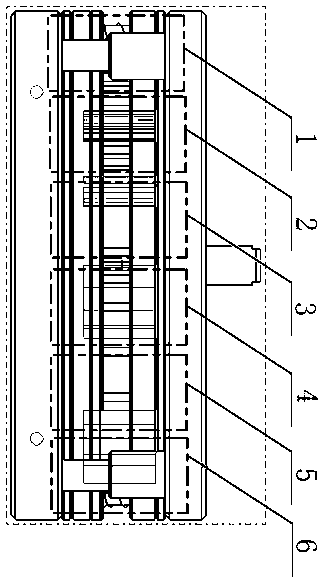

The invention provides a punching method for a serialization porous complex inserting metal piece. The punching method is characterized by including taking a metal piece substrate and placing the metal piece substrate under a blanking die of a first stage punching dispersion hole to disperse punching holes and positioning holes; moving the metal piece after punching hole dispersing to a second stage punching trimming die module, punching remaining hole sites and simultaneously, and punching two corresponding groups of sides without arc incisions on a lower stripe feeding direction and an incision side with an arc on one side; bending two punched symmetric lateral sides without arc incisions; punching a side opposite to the arc incision; bending punched sides with arc incisions; and cutting off connection portions of parts and stripes. According to the punching method and a dedicated die for the serialization porous complex inserting metal piece, adaptability of the die is increased, and further the production efficiency is improved and the service life of the die is prolonged.

Description

technical field [0001] The invention relates to the technical field of stamping dies for a series of porous and complex plug-in metal parts in electronic products, in particular to a high-precision modular progressive die integrating punching and bending. Background technique [0002] At present, for a class of serialized porous and complex plug-in metal parts in electronic products, three methods can be used traditionally: (1) Multiple sets of single-process dies punch out multiple holes, and then use a pair of single-process dies to shape the product. (2) According to the shape characteristics of the product, multiple sets of composite molds are used for step-by-step forming. (3) Using a multi-station progressive die, first punch out positioning holes and multiple holes, then partially blank, then form, and finally cut off to process the product. [0003] In the above (1) and (2) processes, the main disadvantages are: after the transfer of multiple molds, the consisten...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21D35/00B21D37/10

Inventor 王哲英马明旭王哲锋

Owner 南通集智知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com