A synchronous single-sided and double-sided digital inkjet printer and method of wrapping cloth

A digital inkjet, single-sided and double-sided technology, applied to typewriters, printing devices, printing, etc., can solve the problems of idle nozzles, low synchronization accuracy, and slow speed, and achieve the effect of increasing the diameter of the roller and facilitating alignment operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

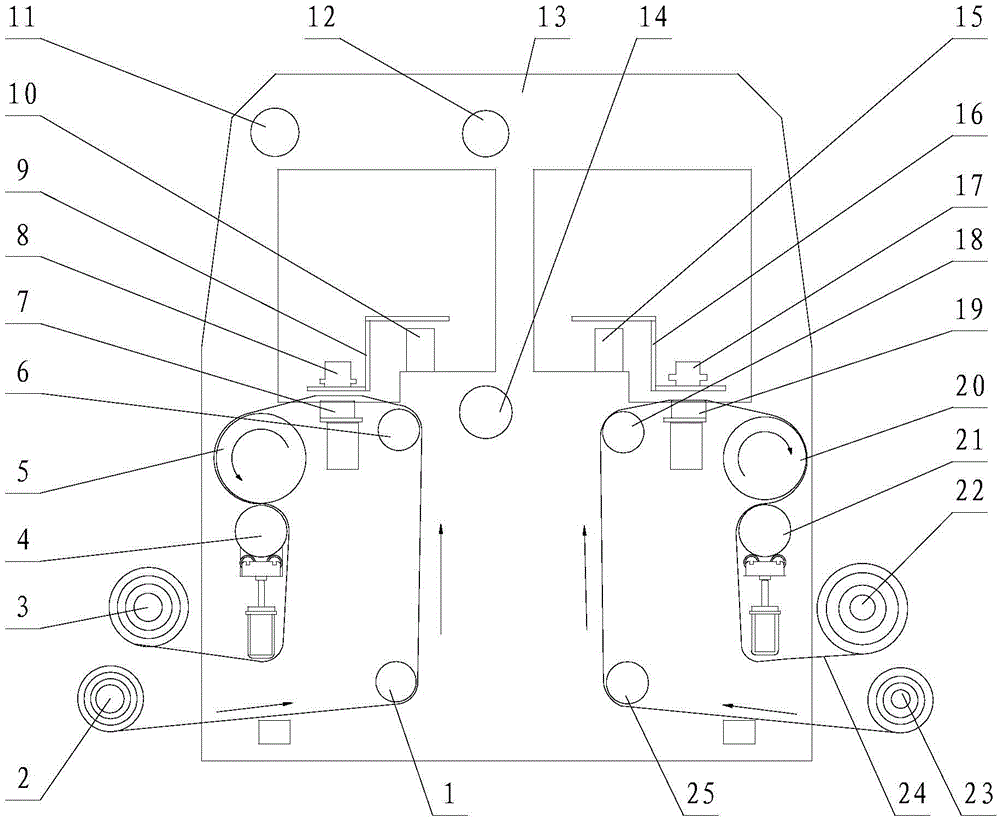

[0022] Embodiment 1 (single spray)

[0023] The digital inkjet printer of this embodiment can carry out single-sided inkjet printing on two canvases 24 simultaneously on one machine, forming a double-speed digital inkjet printer; double-speed is one machine, which can simultaneously perform two single-sided inkjet printing. Such as figure 1 As shown, the digital inkjet printer of the present embodiment comprises a frame, a cloth putting roller, a cloth receiving roller, a back spray dolly 9, a front spray dolly 16, a first driving roller 5 and a second driving roller 20, and the frame is composed of two side walls. Board 13 and the guide rail beam that is installed between two wall boards 13 are formed, and first, second driving roller 5,20 are arranged symmetrically, and are respectively rotated and installed on the wall board 13. The outer sides of the first driving roller 5 and the second driving roller 20 are equipped with two cloth rollers installed on the frame, and the...

Embodiment 2

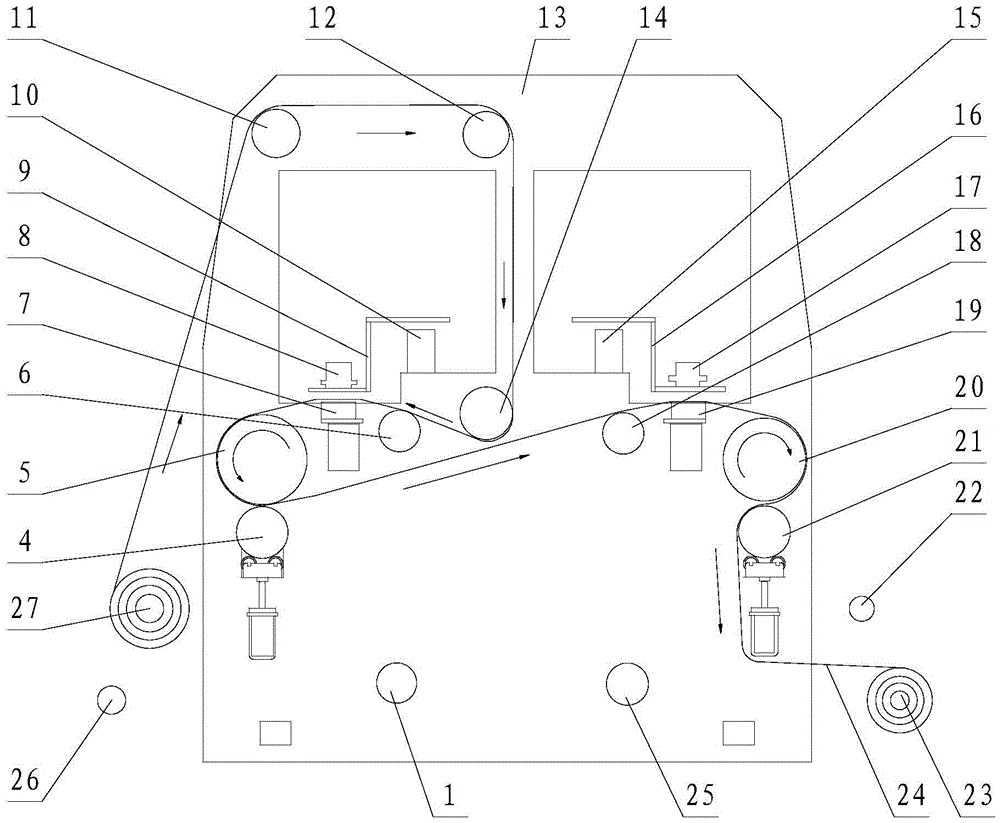

[0029] Embodiment 2 (double spray)

[0030] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that the two cloth rollers outside the first drive roller 5 in the first embodiment, one is the first cloth receiving roller 3 at the top, and the other is the first cloth roller 3 at the bottom. Cloth release roller 2, and the present embodiment uses the first cloth receiving roller 3 as a double spray cloth release roller 27 to carry out cloth release, the first cloth release roller 2 is still used as a single spray cloth release roller 26, does not participate in work in this embodiment ; Similarly, the two cloth rollers on the outside of the second driving roller 20 in the first embodiment, one is the second cloth receiving roller 22 positioned above, and the other is the second cloth releasing roller 23 positioned below, and the present embodiment will The second cloth receiving roller 22 is still used as the single-spray receiving ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com