Stamping method and special mold for serialized porous and complex plug-in metal parts

A technology for inserting metal parts and metal parts, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem of poor consistency of the size and shape errors of the parts, affecting the accuracy of the parts and the life of the mold, quality and forming accuracy Difficult to guarantee and other problems, to achieve the effect of less stress concentration, less uneven deformation, and improved mold working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0034] Detailed ways: Below in conjunction with accompanying drawing, the present invention is further described:

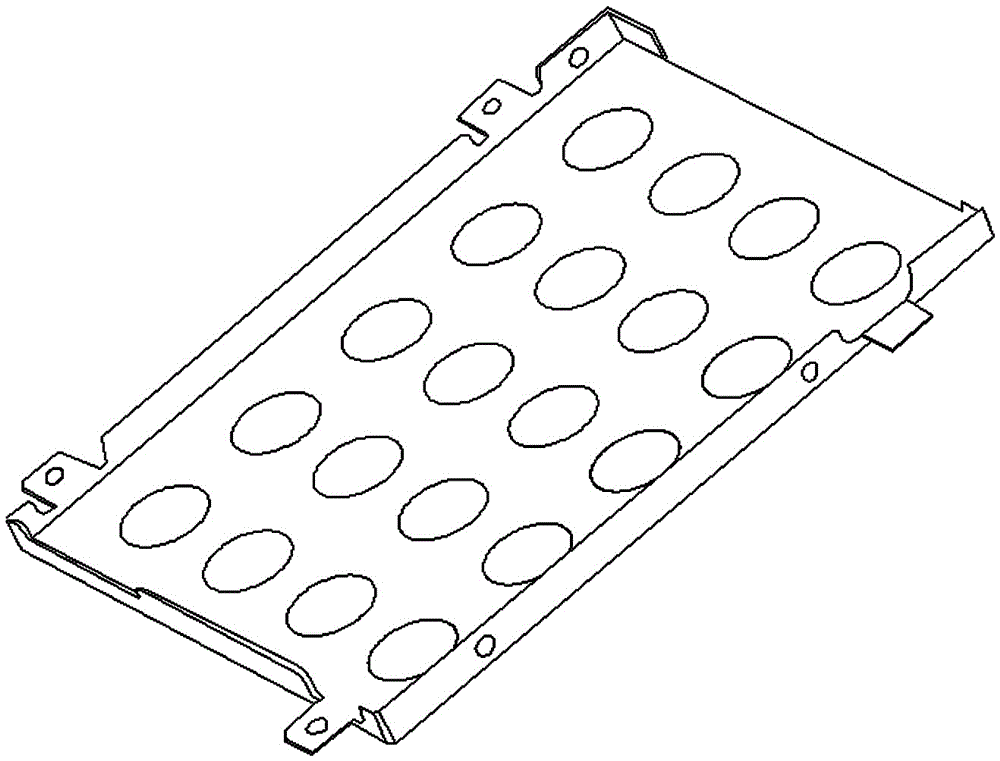

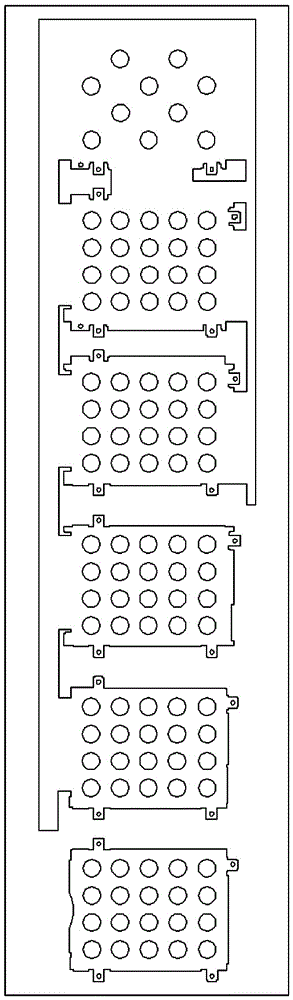

[0035] The invention provides a stamping method for serialized porous and complex plug-in metal parts, such as figure 2 As shown, combined with the process design plan and the shape and size requirements of the product, the layout process plan of the parts has been formulated. The process flow is: punching scattered holes and positioning holes ----- punching the remaining scattered holes and punching two arc-free The corresponding side of the square incision and the side with arc side notch--the opposite side of the curved two without arc-shaped notch---the opposite side of punching with arc-shaped notch--the arc-shaped notch after punching Bend the two sides and the opposite side ----- cut off the connecting part of the part and the strip.

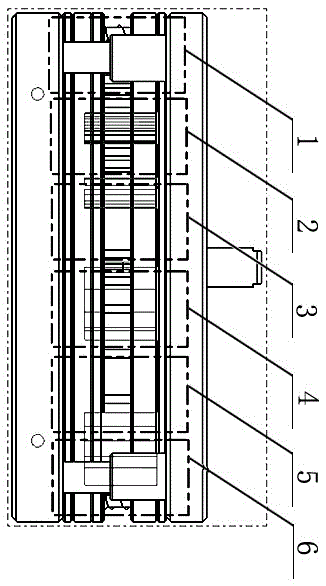

[0036] like image 3 Each of the shown stations is designed with an independent mold structure, and the mold includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com