Through type continuous folded plate structure suitable for tail edge part of turbine blade

A technology of turbine blade and folded plate structure, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of large flow loss, low outlet turbulence, and difficulty in achieving uniform and stable inlet airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

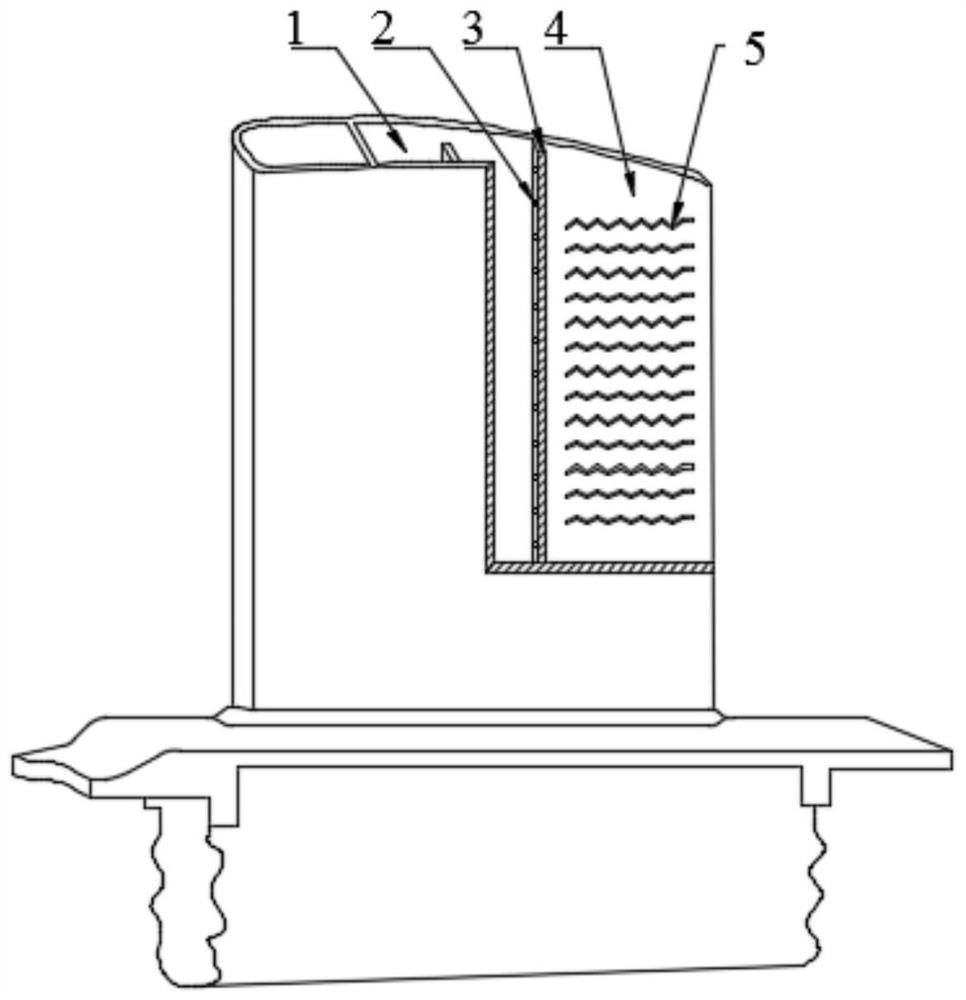

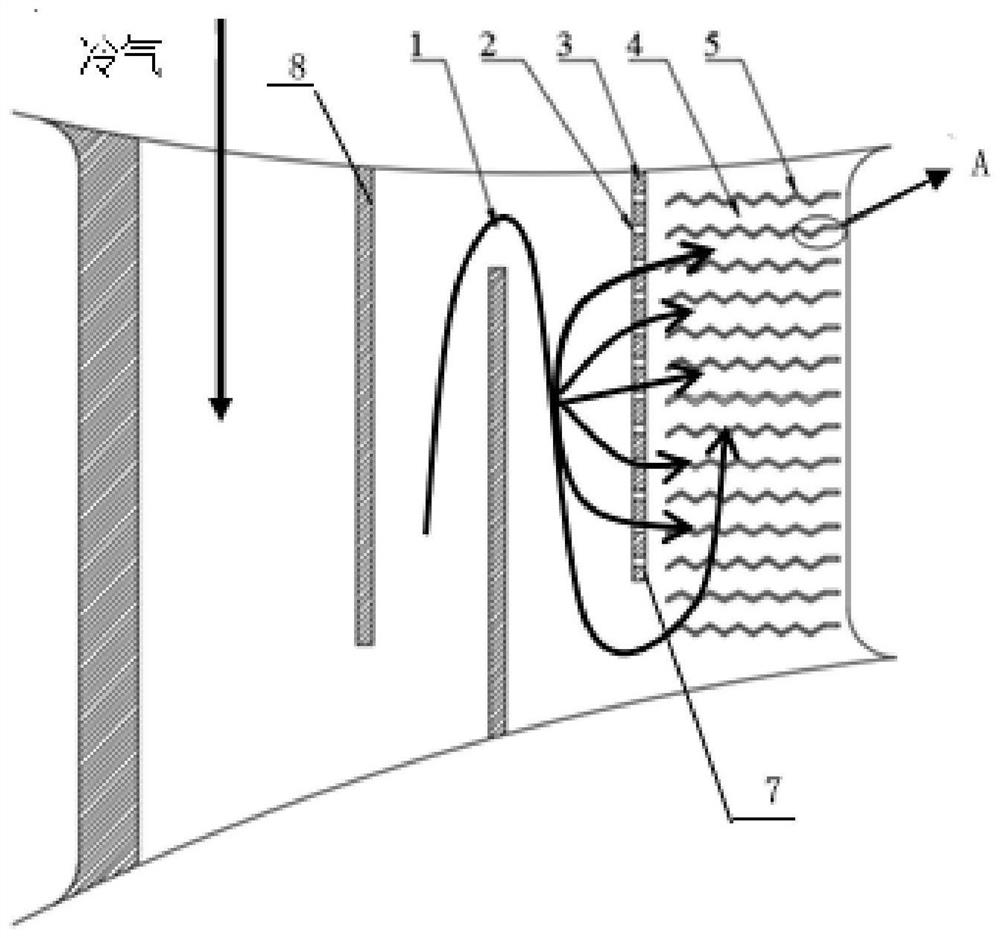

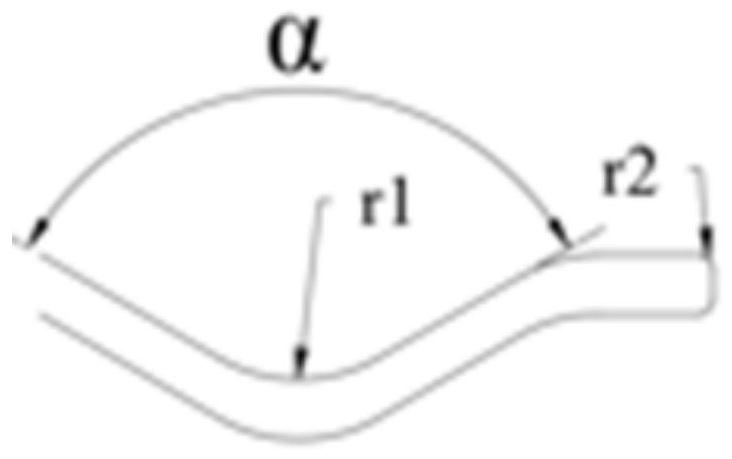

[0026] Such as Figures 1 to 3 As shown, a through-type continuous folded plate structure suitable for the trailing edge of the turbine blade of the present invention includes a U-shaped cooling channel 1 and a cooling cavity 4 for the trailing edge of the blade, and the U-shaped cooling channel is located at the end of the blade. The leading edge and the middle part, the blade trailing edge cooling cavity 4 is located at the blade trailing edge, and the U-shaped cooling channel position 1 is separated from the blade trailing edge cooling cavity 4 by a side wall surface 7, and the bottom of the side wall surface 7 is provided with an opening, which serves as At the outlet of the U-shaped cooling passage 1, a number of air holes 3 are opened in the side wall surface 7, and multiple rows of through-type continuous folded plates 5 are arranged in the cooling chamber 4 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com