Offset hole row and cylindrical hole row combined cooling structure for corrugated heat shield

A corrugated heat shield and cooling structure technology, applied in lighting and heating equipment, combustion methods, combustion chambers, etc., can solve problems such as the existence of optimized space and the configuration of air film holes that are not optimized, and achieve improved cooling efficiency. Cooling effect, effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

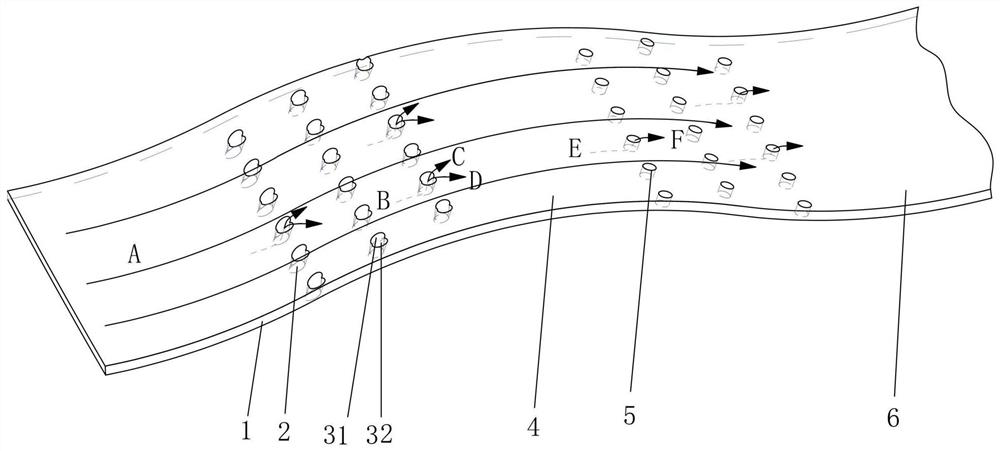

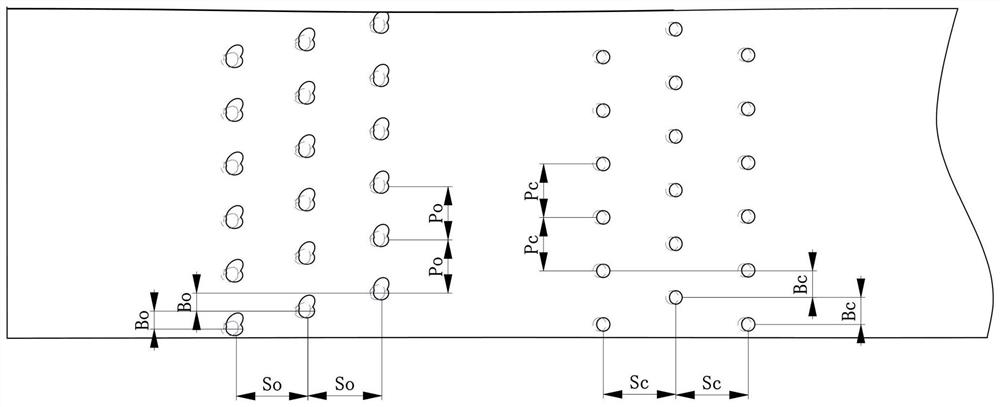

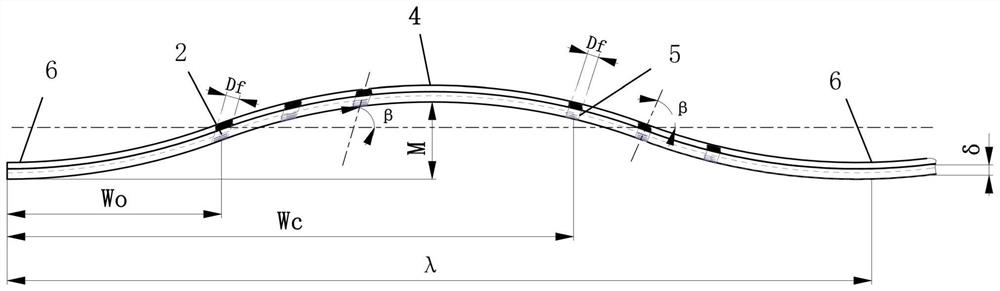

[0040] This embodiment is a combined cooling structure of offset air film hole rows and cylindrical hole rows on the corrugated heat shield. Two rows of offset air film hole rows 2 are arranged on the windward side of the corrugated heat shield, and four rows of cylindrical hole rows 5 are arranged on the leeward surface of the corrugated heat shield. The annular cold air passage surrounded by the heat shield cylinder and the outer combustion chamber cylinder supplies air. The offset air film hole in the offset air film hole row 2 is composed of a cylindrical air film hole and an offset rotating cylindrical hole. The cylindrical air film hole is a circular through hole, and the offset rotating cylindrical hole is The cylindrical air film holes are formed offset around the center of the hole on the side of the cold air channel; the offset air film hole row 2 is concentrated on the second half of the windward side, and there is a small offset distance between adjacent hole rows,...

Embodiment 2

[0045] This embodiment is a combined cooling structure of offset air film hole rows and cylindrical hole rows on the corrugated heat shield. Three rows of offset hole rows 2 are arranged on the windward side of the corrugated heat shield panel 1, and four rows of cylindrical hole rows 5 are arranged on the leeward side of the corrugated heat shield panel 1. Both the offset air film hole row and the cylindrical hole row are made of corrugated The annular cold air passage surrounded by the heat shield plate and the outer combustion chamber cylinder supplies air. The offset air film hole in the offset air film hole row 2 is composed of a cylindrical air film hole and an offset rotating cylindrical hole. The cylindrical air film hole is a circular through hole, and the offset rotating cylindrical hole is The cylindrical air film holes are formed offset around the center of the orifice on the side of the cold air passage; the offset air film hole rows are concentrated in the rear h...

Embodiment 3

[0050] This embodiment is a combined cooling structure of offset air film hole rows and cylindrical hole rows on the corrugated heat shield. Three rows of offset hole rows 2 are arranged on the windward side of the corrugated heat shield panel, and five rows of cylindrical hole rows 5 are arranged on the leeward side of the corrugated heat shield panel. The annular cold air channel surrounded by the cylinder supplies air. The offset air film hole in the offset air film hole row 2 is composed of a cylindrical air film hole and an offset rotating cylindrical hole. The cylindrical air film hole is a circular through hole, and the offset rotating cylindrical hole is The cylindrical air film holes are formed offset around the center of the hole on the side of the cold air channel; the offset air film hole row 2 is concentrated on the second half of the windward side, and there is a small offset distance between adjacent hole rows, and the cylindrical hole row Concentrated in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com