Electric power plant water diversion open ditch flow guide heat insulation device and design method thereof

A technology of heat insulation device and open channel, which is applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve the problems of output reduction, loss of economic benefits, influence on the design power of generator sets, etc., so as to reduce operating back pressure and improve Efficiency, effect of increasing annual power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

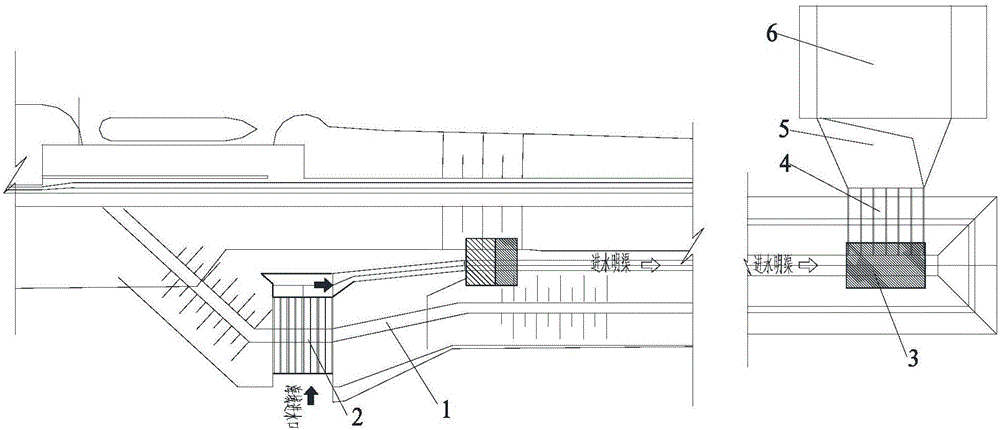

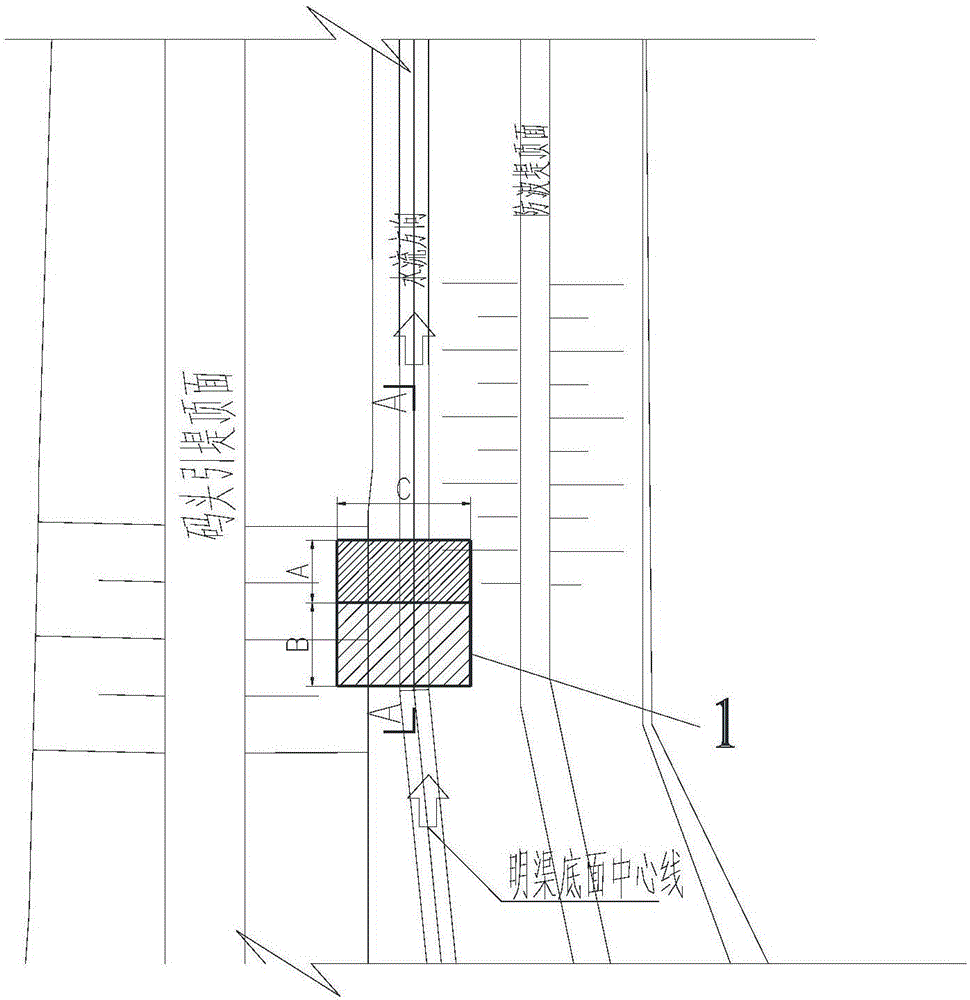

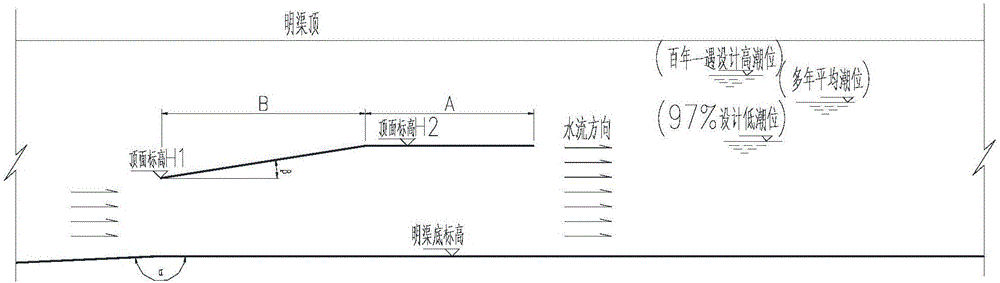

[0037] In this embodiment, by obtaining the design parameters of the current water diversion open channel, including the bottom slope turning angle, the design low tide height, the end surface parameters of the water diversion open channel, and the hydraulic gradient of the water diversion open channel; obtaining the design parameters of the current rectifying box culvert, including width and inner top elevation; Obtain the parameters of the current water area, such as the solar radiation temperature rise value per unit length of the water area; use fluid mechanics software to propose the specific structure of the diversion channel heat insulation device of the power plant described in this embodiment after a large number of optimization calculations. In this embodiment, the diversion heat insulation board is composed of a folded plate type deflector arranged at the entrance of the open channel (after the water diversion box culvert slope change section) and a flat plate type gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com