Water spray quenching technology for wheel treads of industrial and mining locomotives, cranes and the like

A wheel tread, water spray quenching technology, applied in the direction of quenching agent, quenching device, manufacturing tools, etc., can solve the problems of large hardness gradient between the hardened layer and the core, peeling of the hardened layer and the core, and reduced service life of the workpiece. Achieve the effect of not easy to quench cracking, obvious delamination, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described on the basis of examples below:

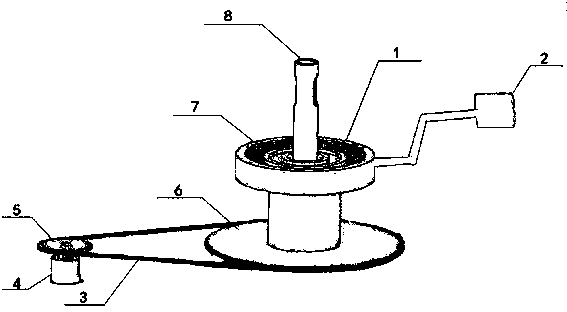

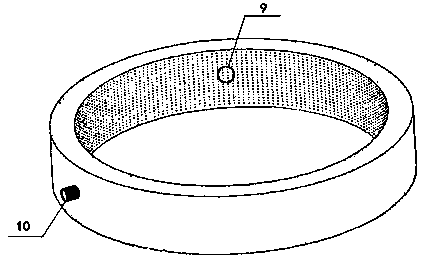

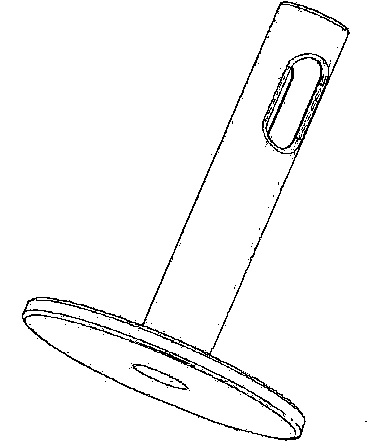

[0018] First of all, check whether there are cracks on the surface of the wheel, and those with cracks are not allowed to undergo heat treatment. Choose the appropriate water spray ring according to the size of the wheel, because several different water spray rings should be designed and manufactured according to the wheel size. The water spray ring is made of 2mm steel plate. Generally, the inner diameter of the water spray ring is 40mm-80mm larger than the outer diameter of the wheel. After the water ring is selected, first cold-install the wheel to test the position of the water spray. The distance between the water spray ring and the outer circle of the wheel should be the same. The water sprayed by the water ring should be below the upper rim. Check whether the water spray hole is sprayed. Put the wheels into the heat treatment furnace and preheat them at 600°C for 2-3 hours, then heat the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com