Oxygen humidifying bottle

A technology of oxygen humidification and oxygen, which is applied in the field of medical equipment, can solve the problems of short contact time of distilled water, uncontrollable, unreachable humidification, etc., and achieve the effect of increasing the humidification effect, prolonging the journey and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

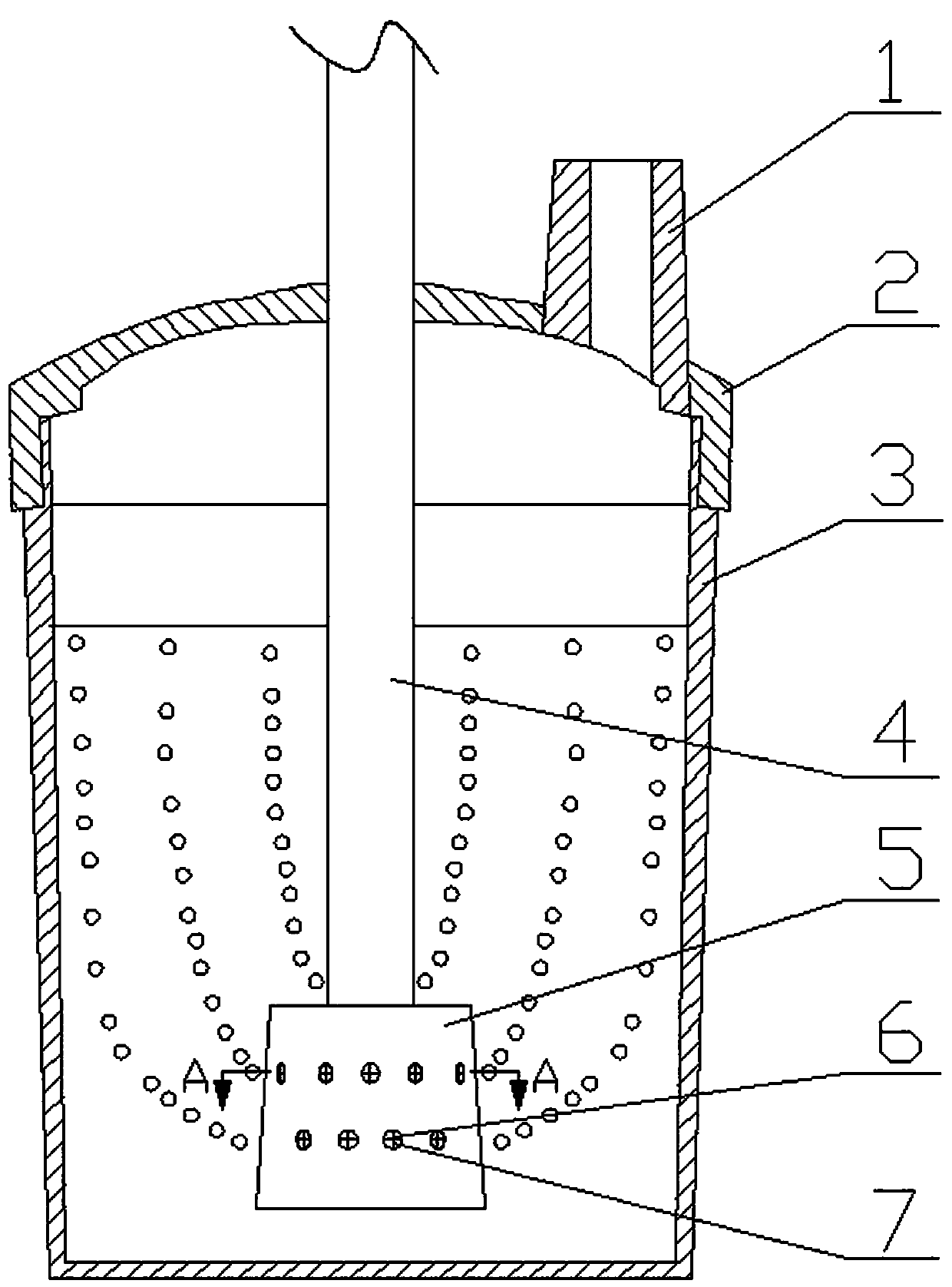

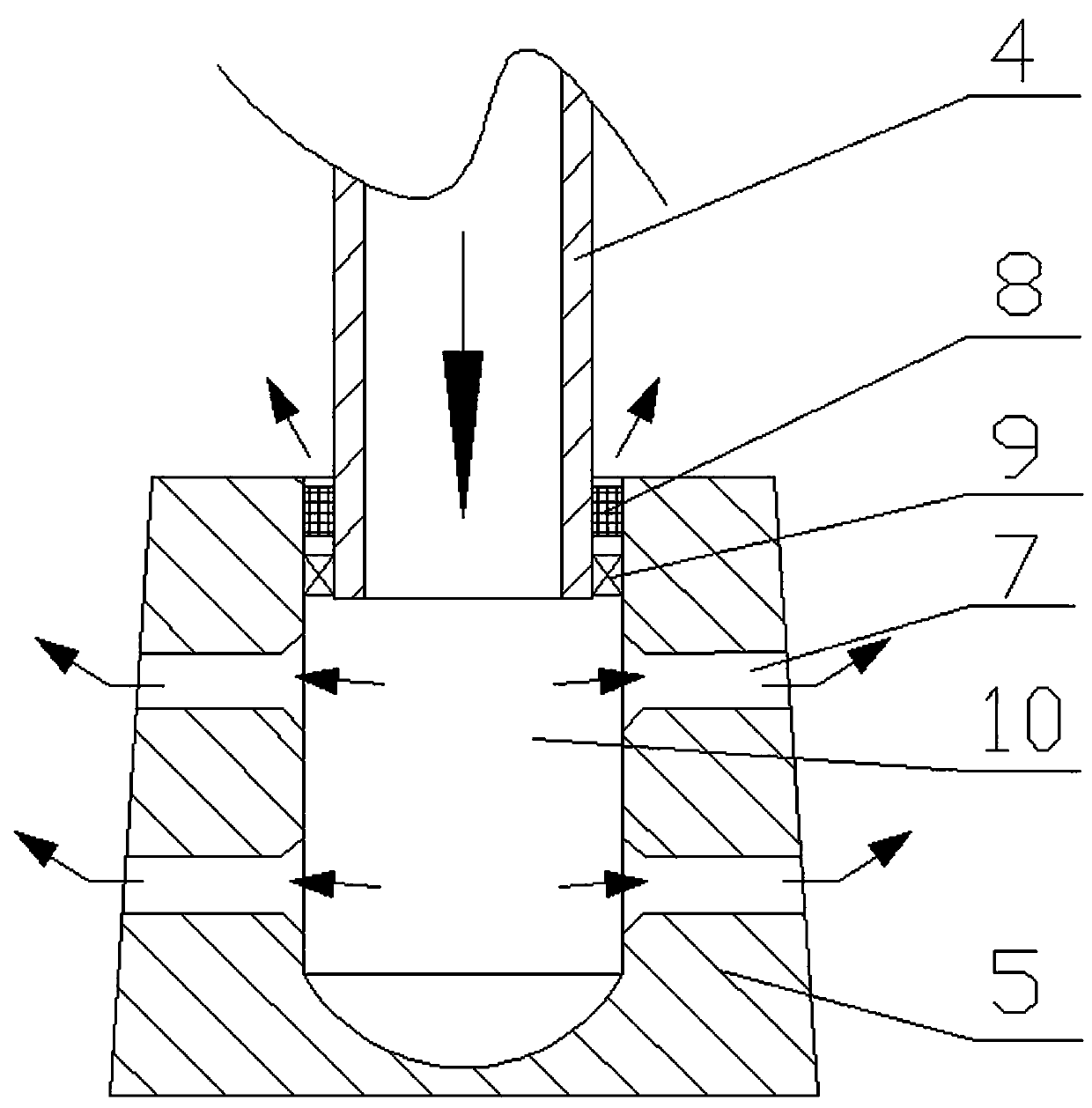

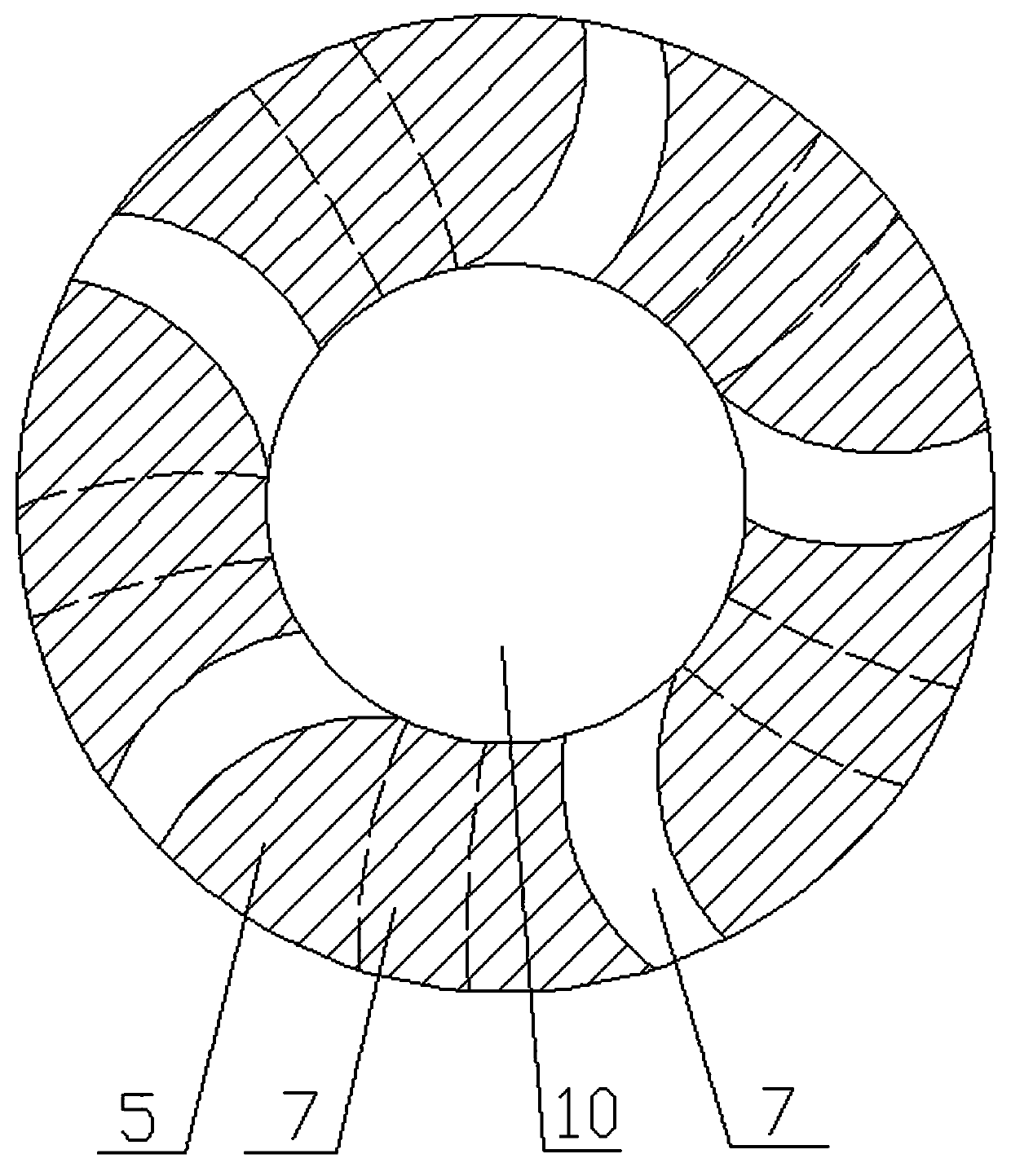

[0023] Such as figure 1 As shown, an oxygen humidification bottle of the present invention includes a bottle body 3 , a bottle cap 2 , and an oxygen inlet pipe 4 and an oxygen exhaust pipe 1 inserted in the bottle cap 2 . The bottle body 3 is filled with distilled water, and the lower end of the oxygen inlet pipe 4 is inserted in the distilled water and close to the bottom of the bottle body 3, so that the oxygen flowing through the oxygen inlet pipe 4 generates bubbles in the distilled water and fully contacts with the distilled water Afterwards, it escapes from the liquid surface of distilled water, and then is collected by the oxygen exhaust pipe 1 and then discharged from the bottle body 3 for inhalation by the patient.

[0024] Different from the humidification bottle in the prior art, the present invention is provided with an oxygen humidification mechanism at the lower end of the oxygen inlet pipe 4 . And the specific surface area of the bubbles and the travel time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com