Patents

Literature

42results about How to "Reduce the effect of temperature rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

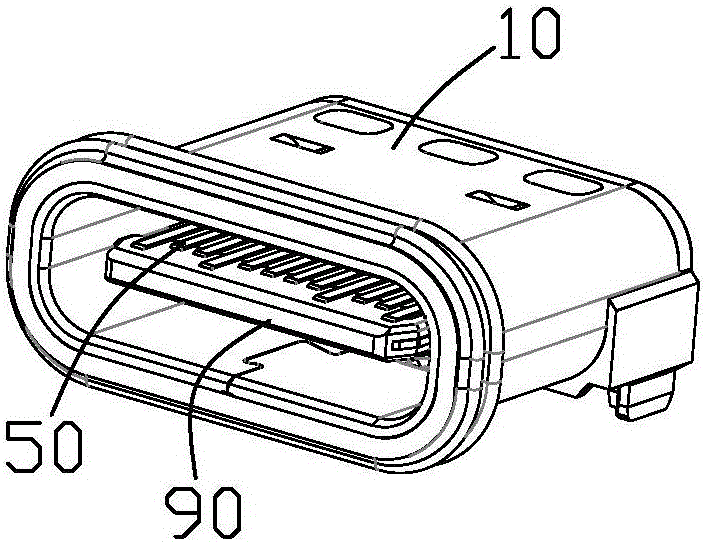

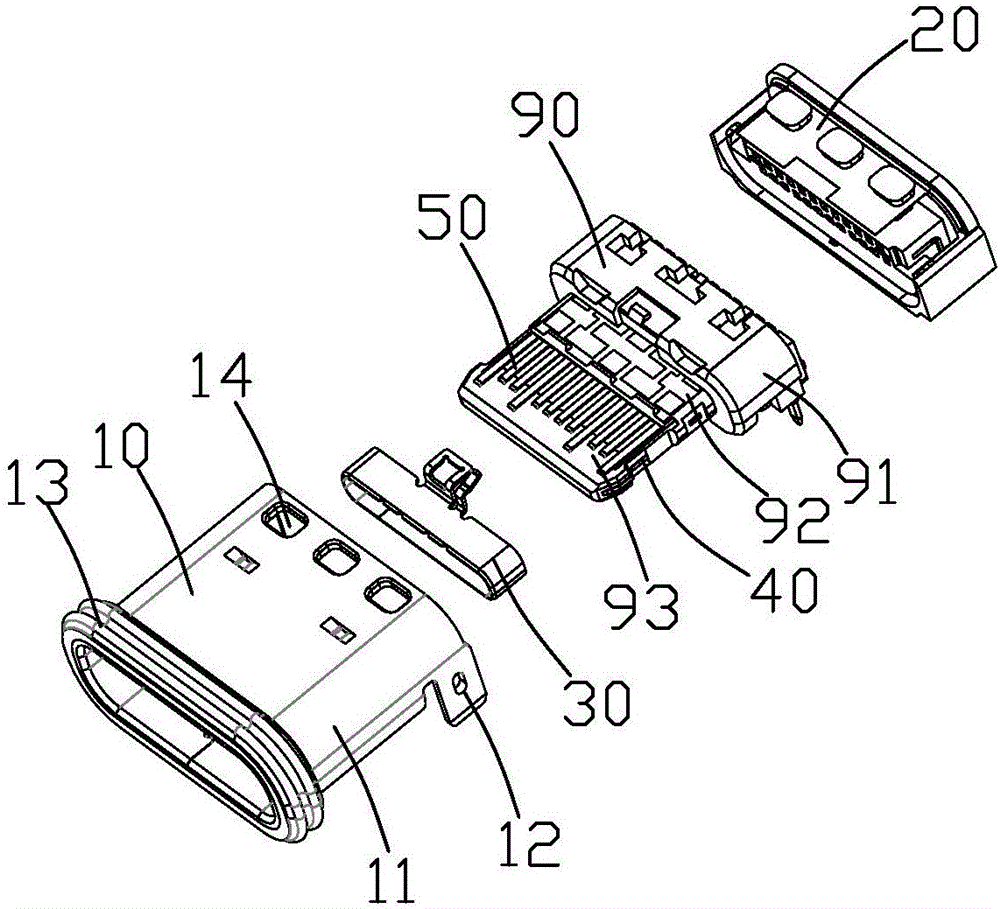

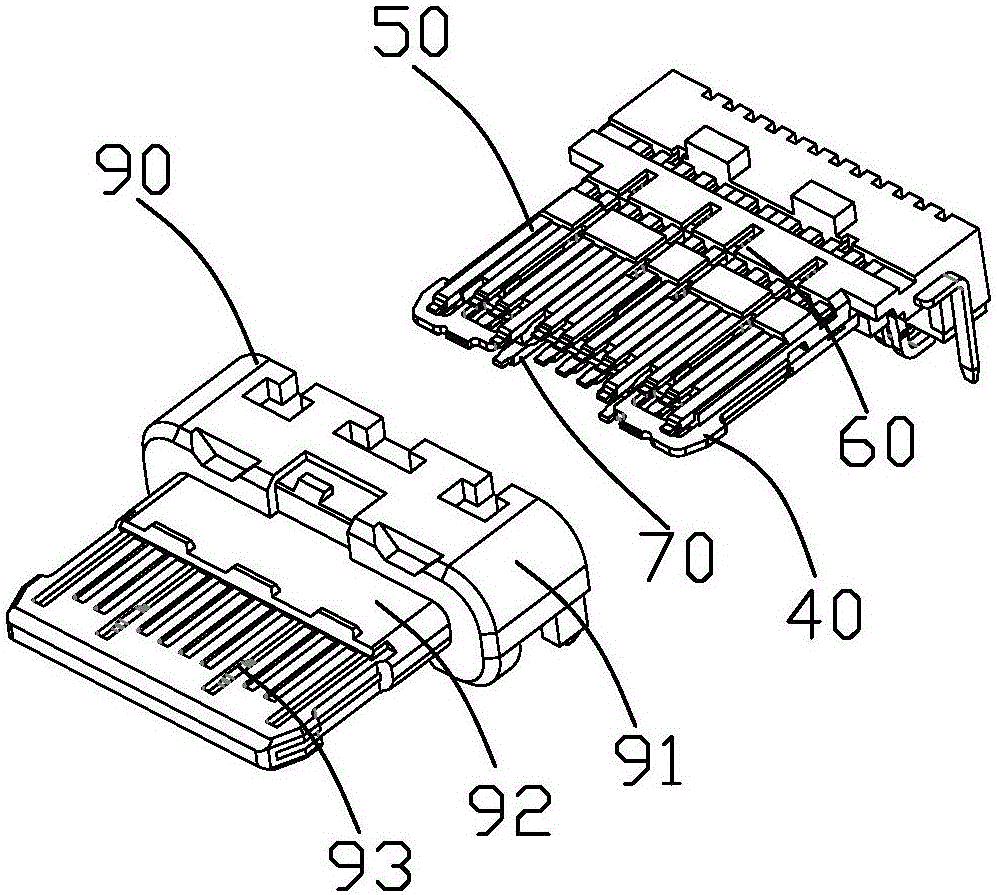

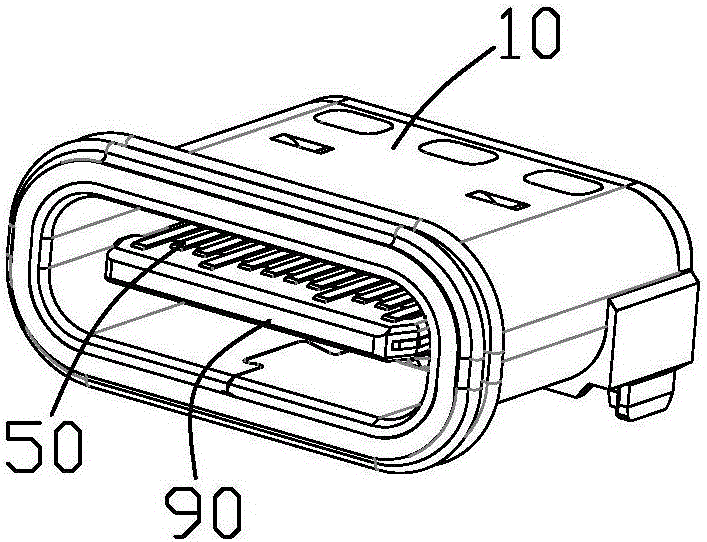

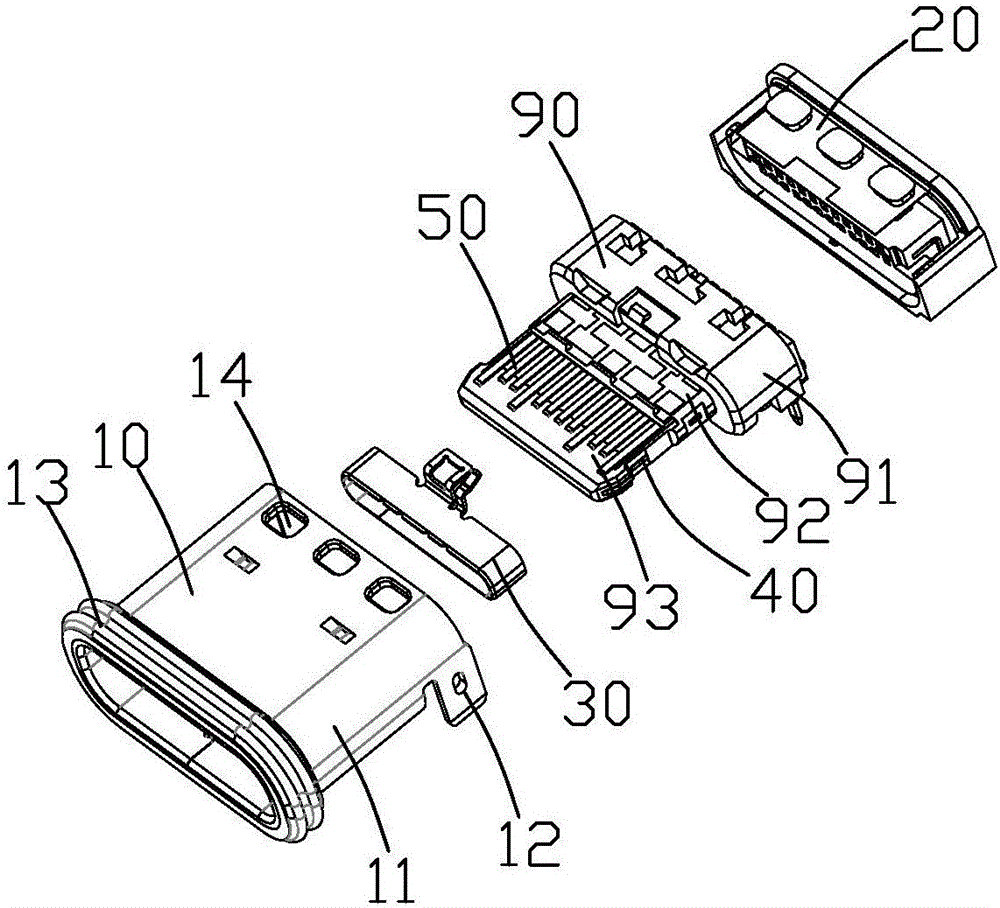

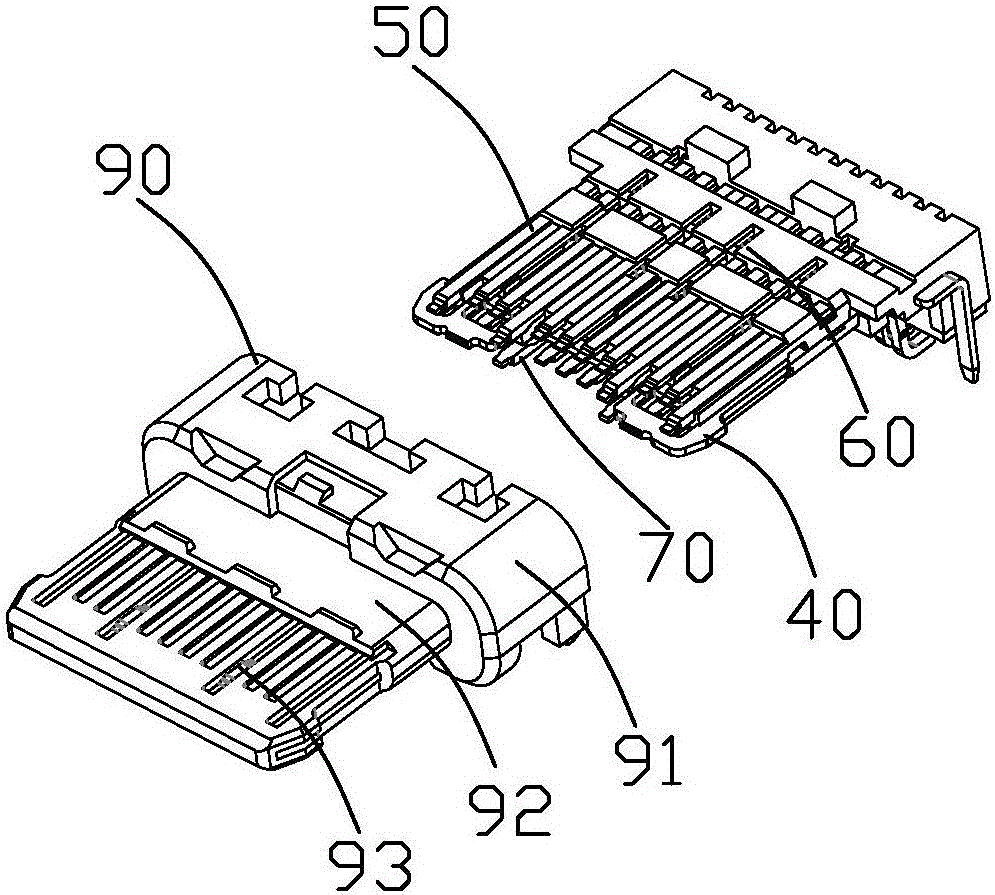

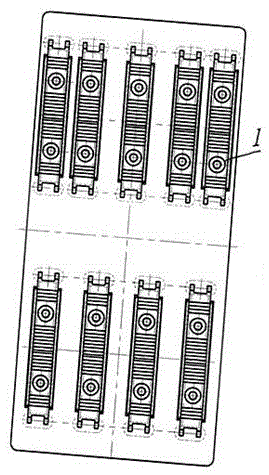

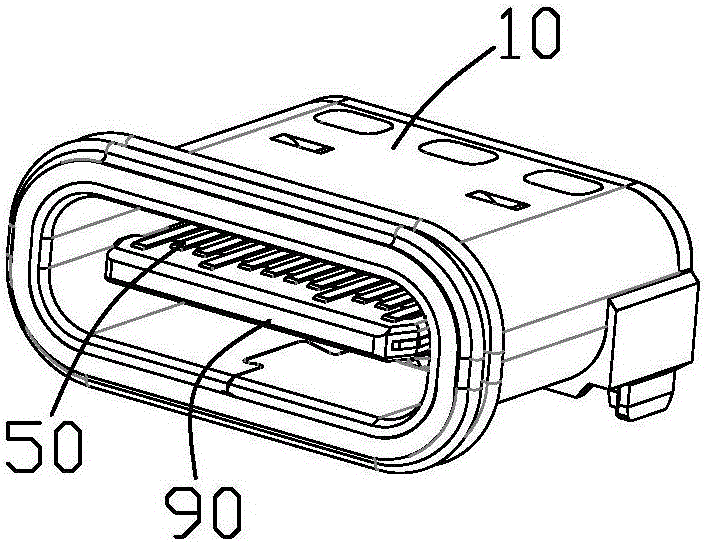

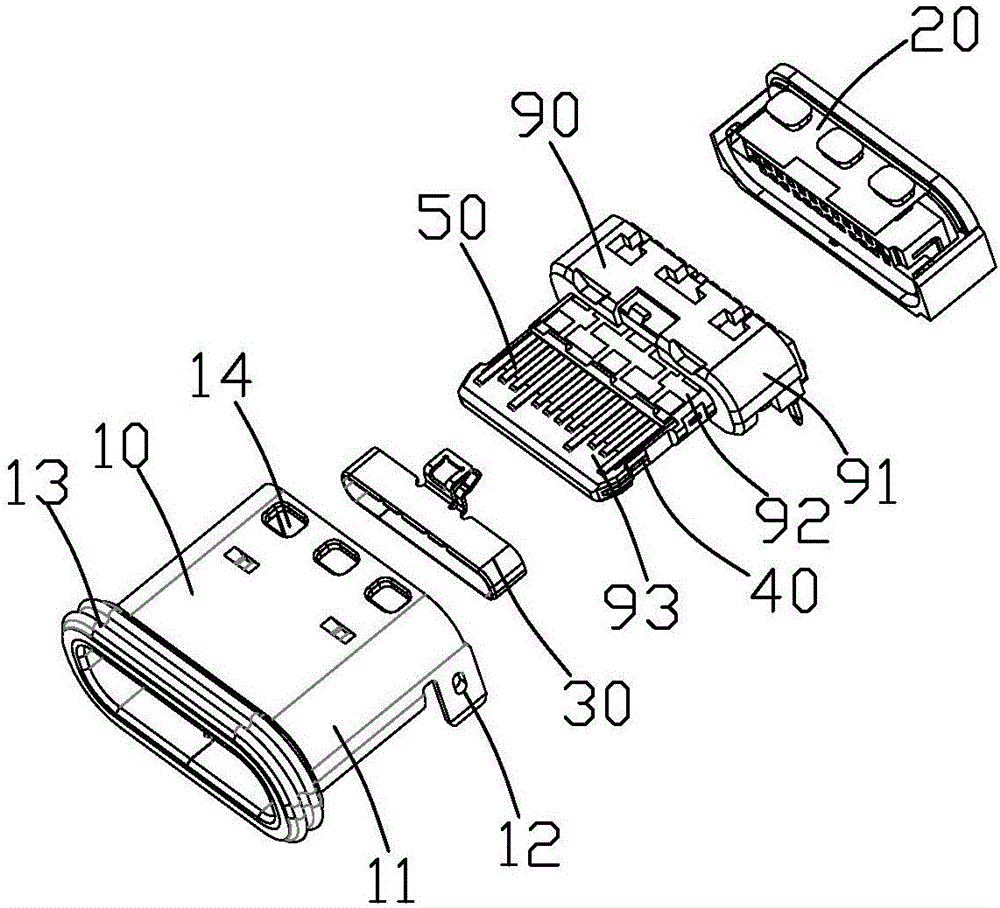

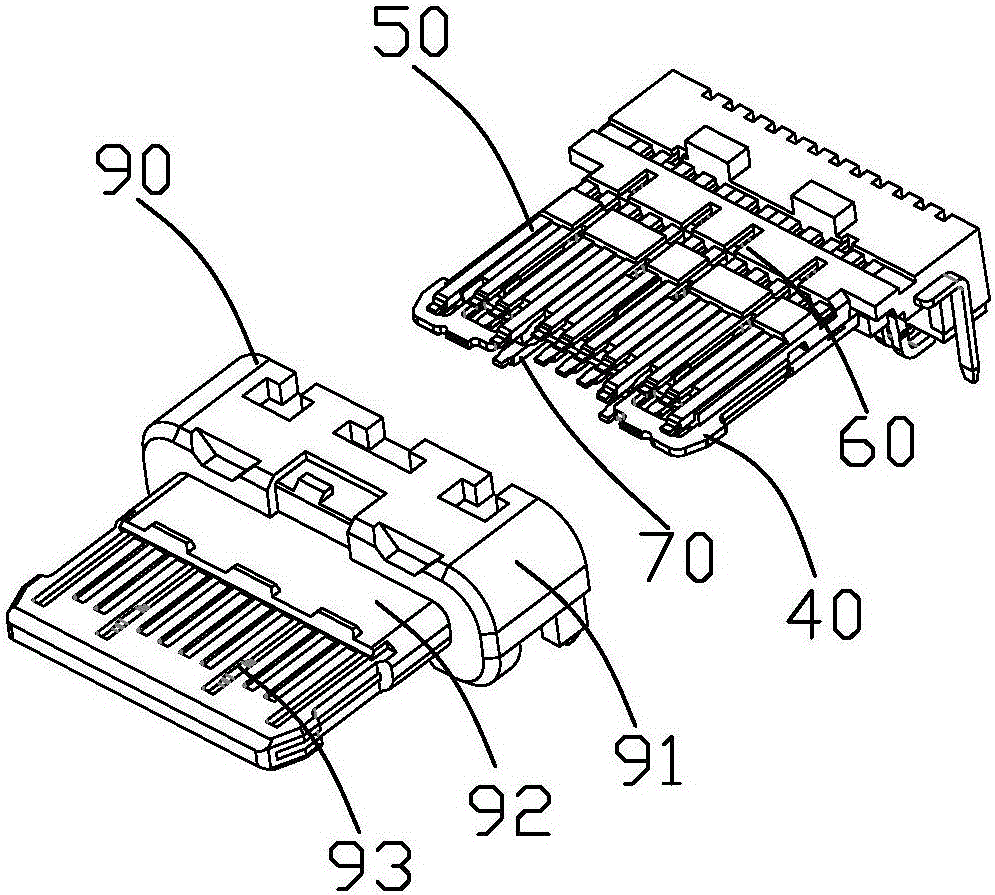

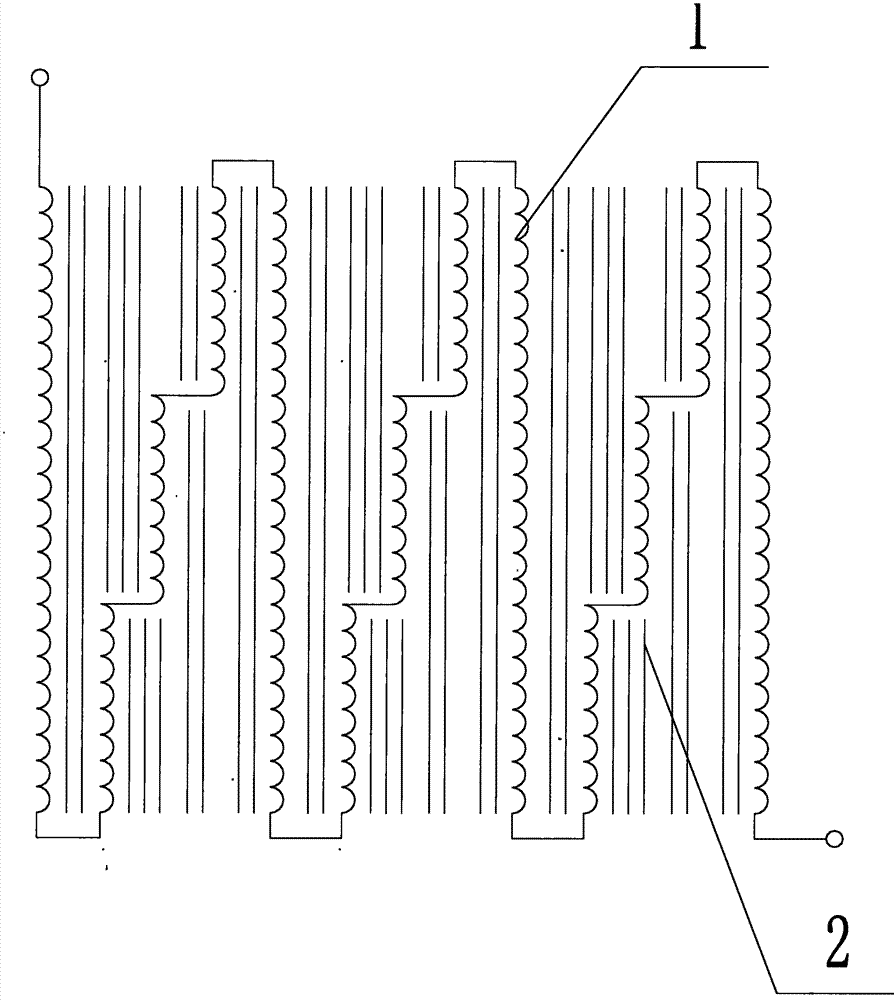

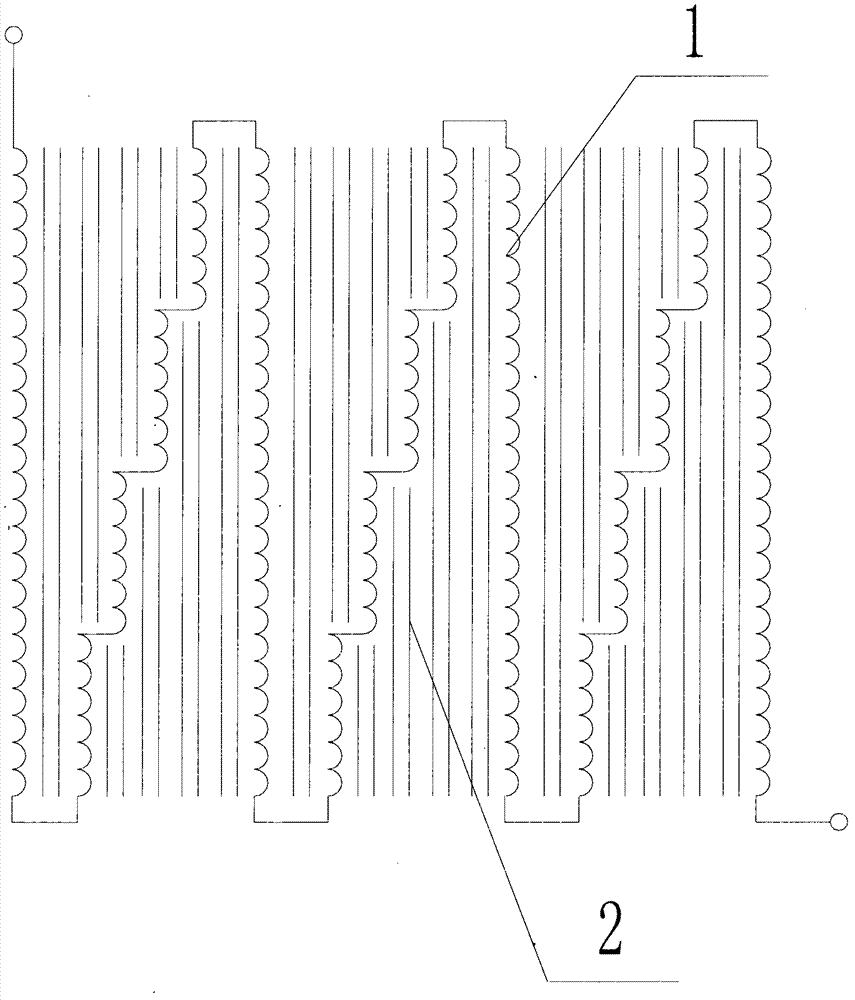

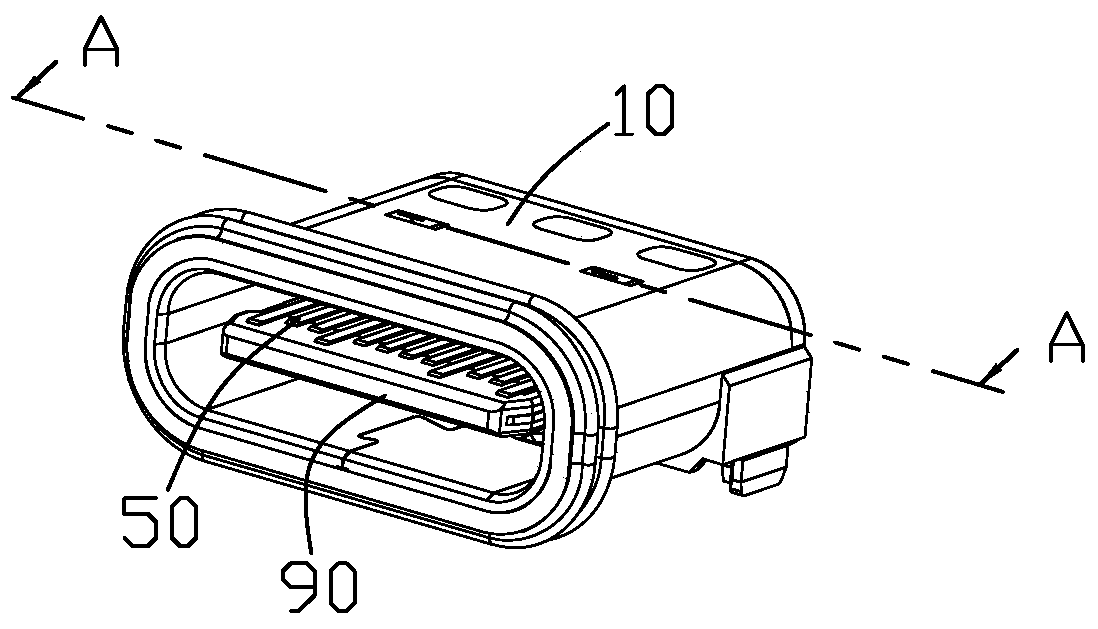

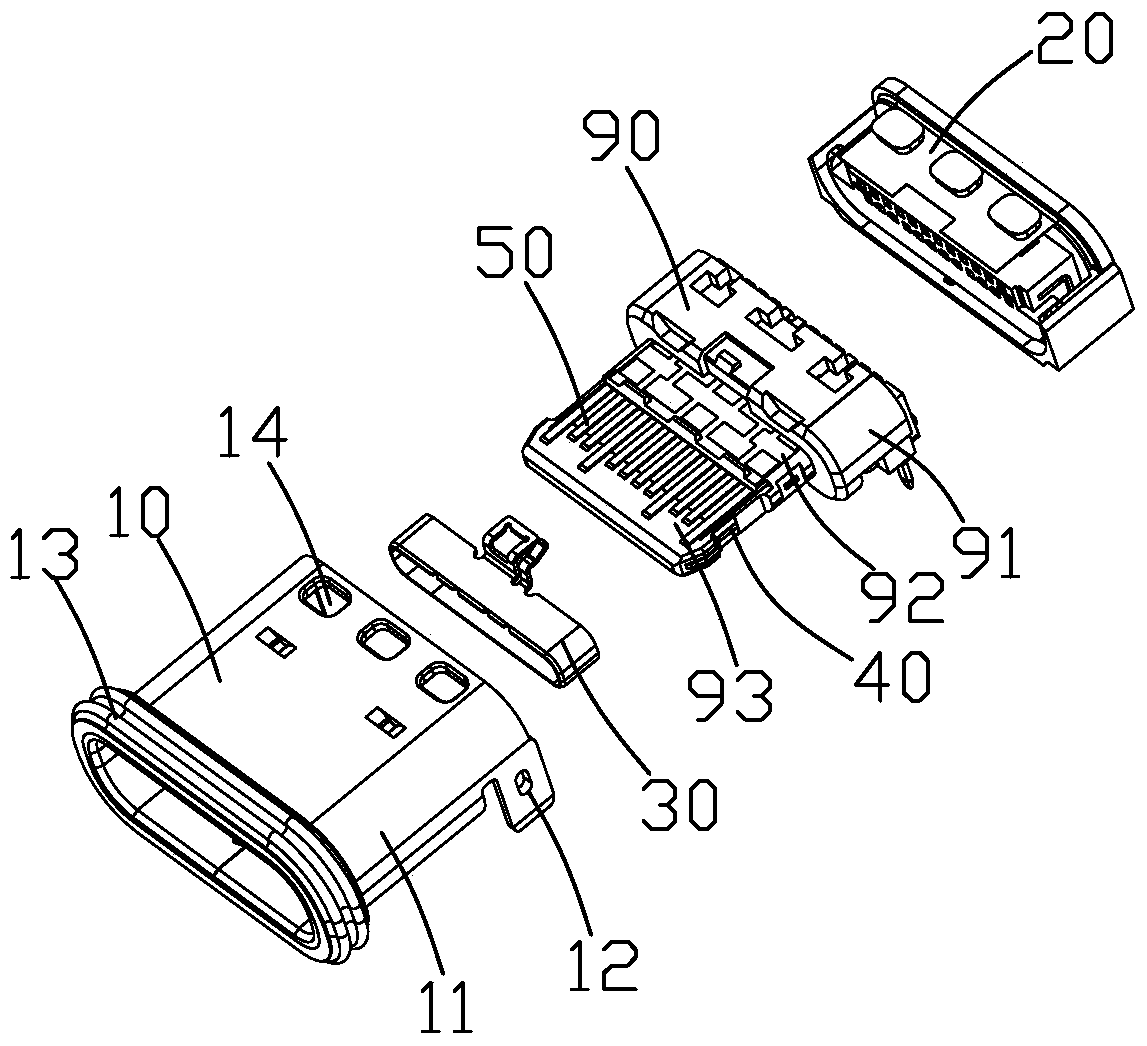

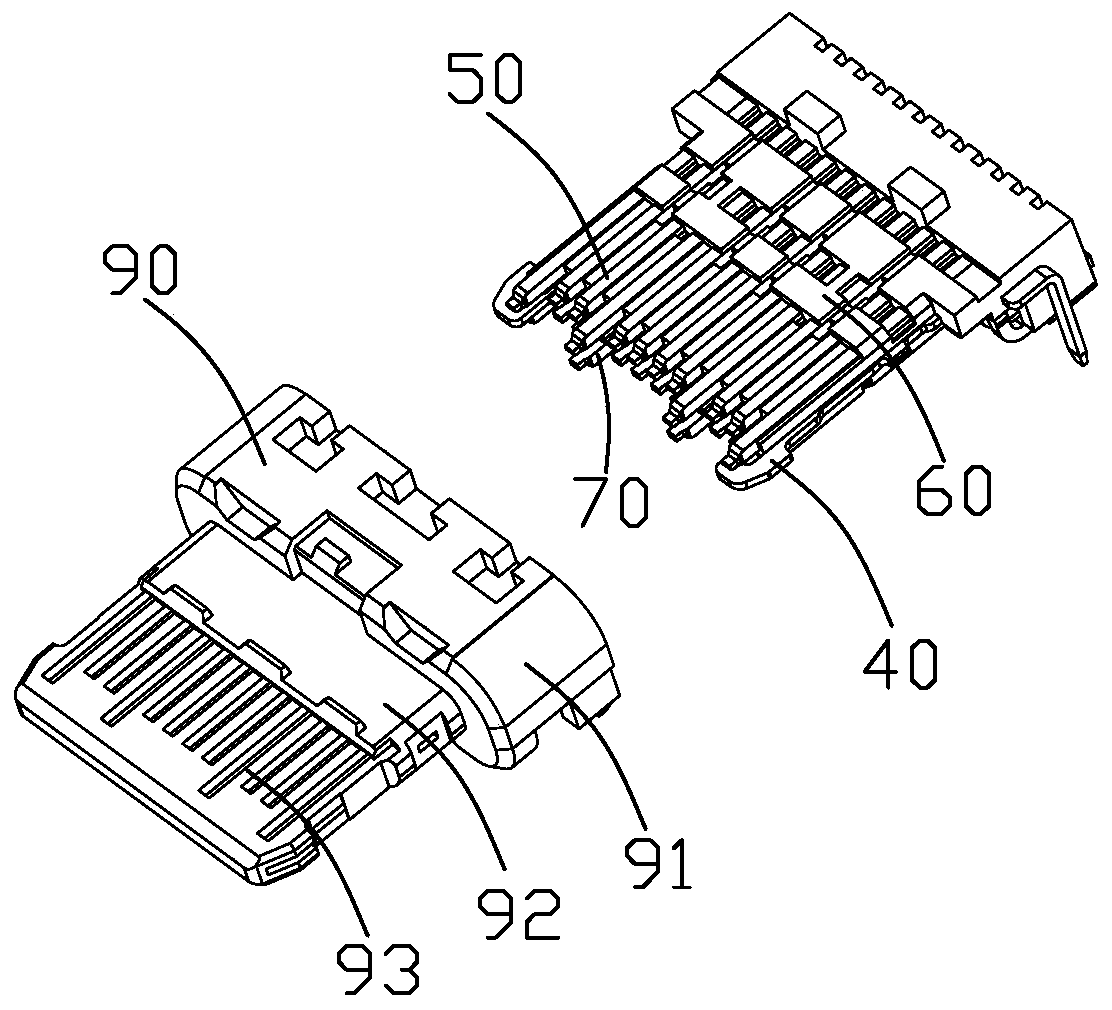

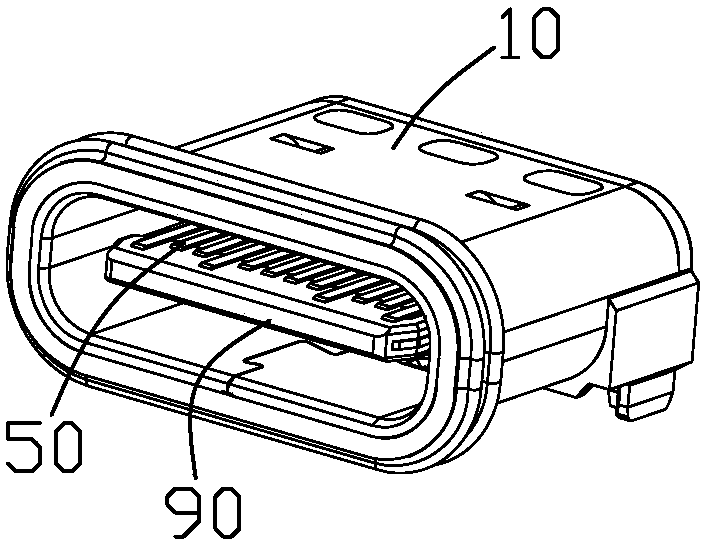

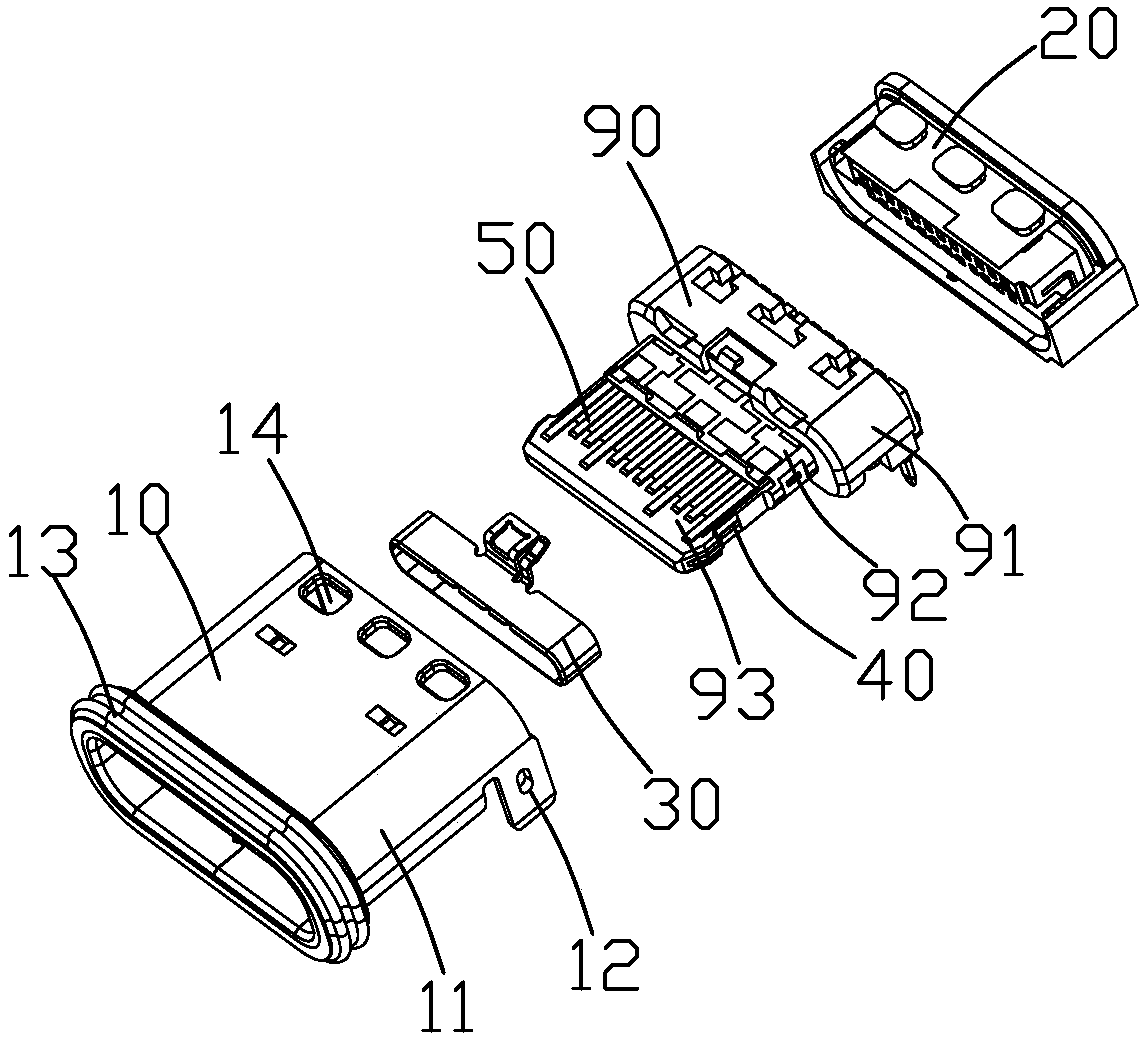

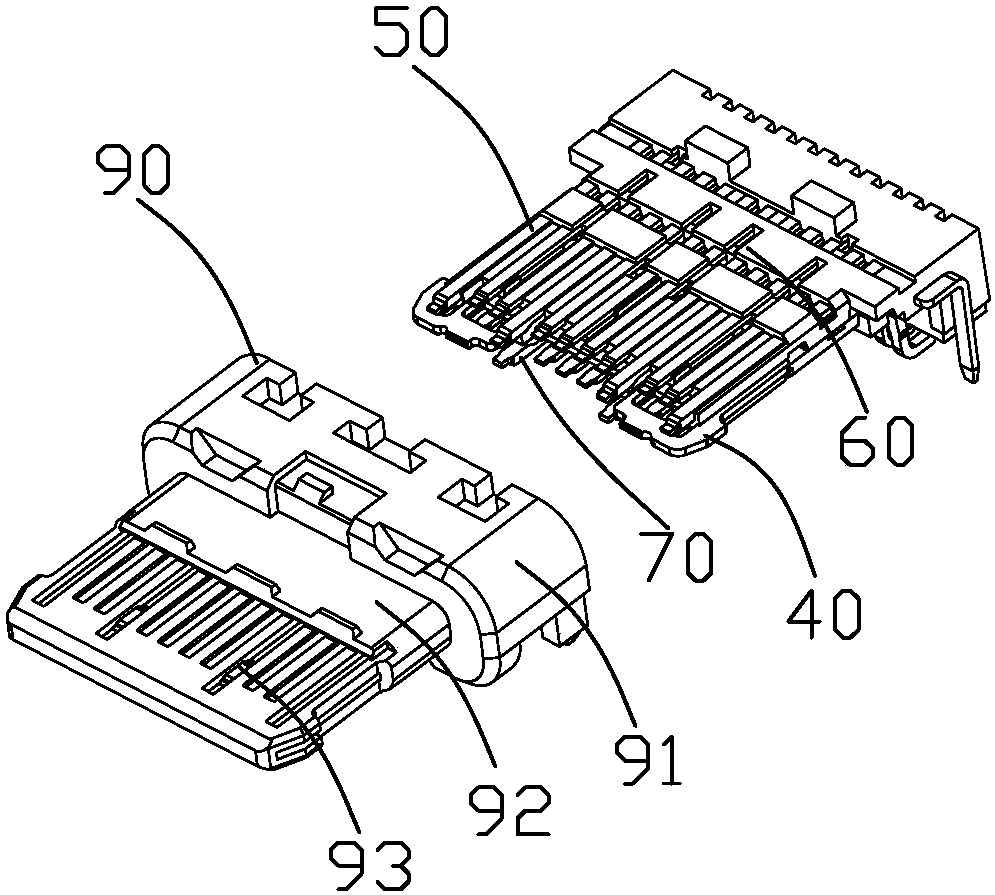

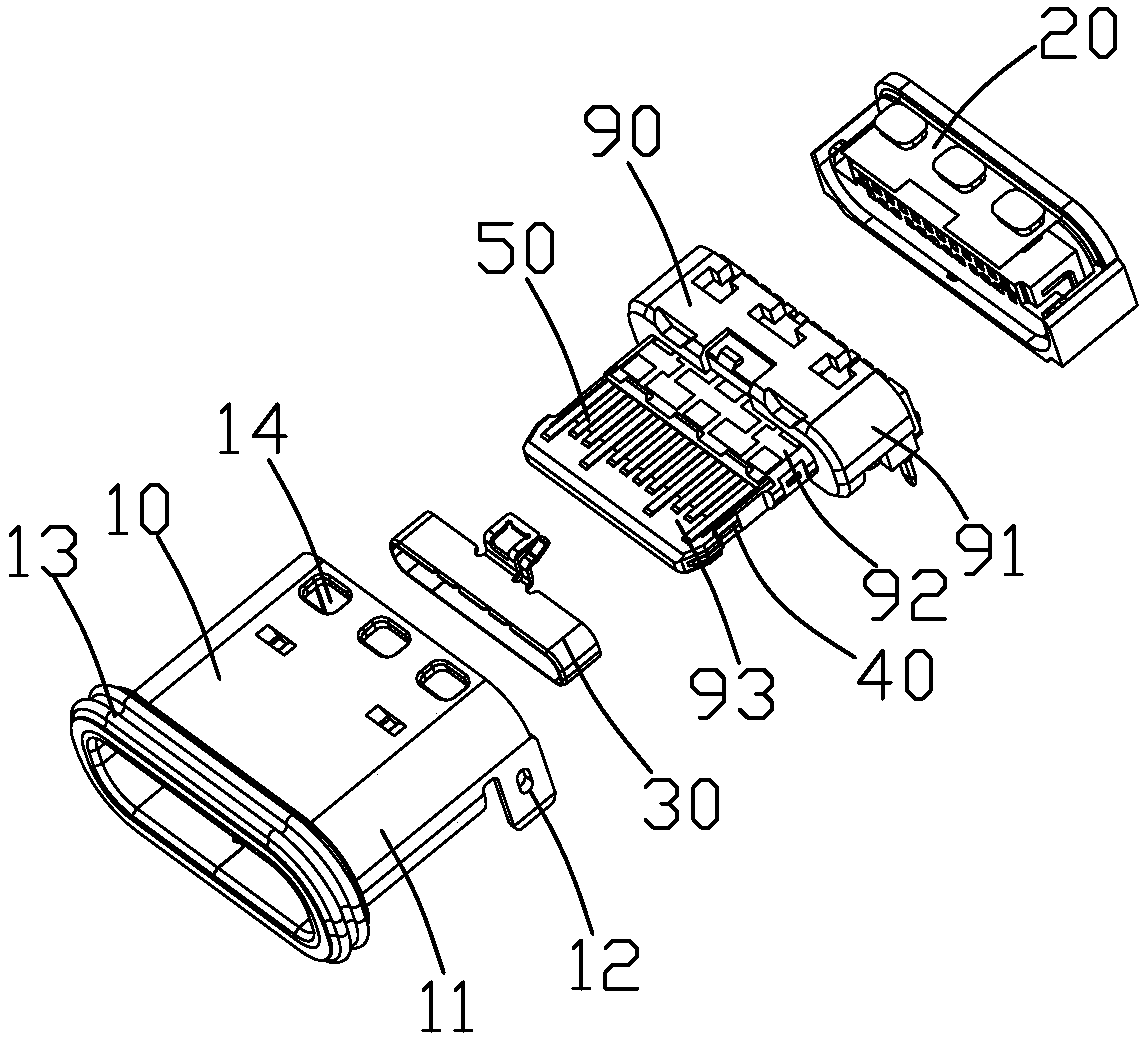

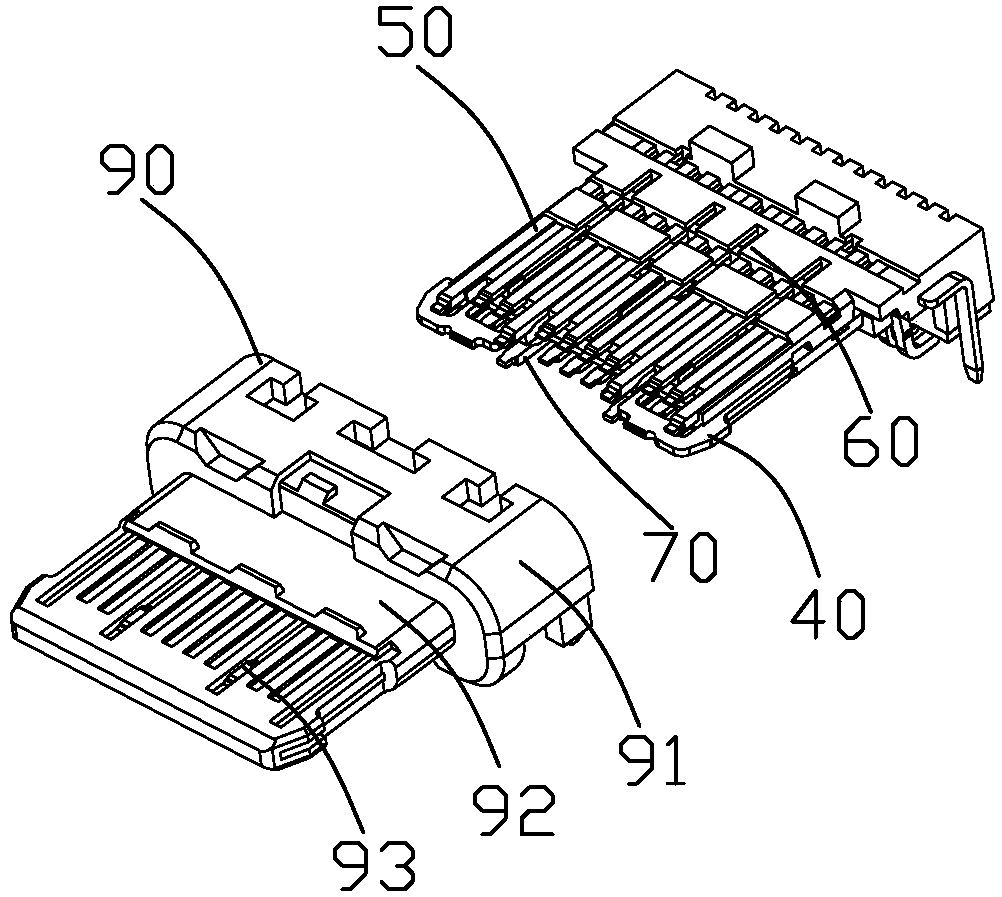

High-current USB Type C socket and manufacturing method thereof

ActiveCN106025638ALower impedanceEnhanced current flowSecuring/insulating coupling contact membersCoupling contact membersUSBHigh current

The invention relates to a high-current Type C socket, which comprises a metal medium plate, a first terminal group, a second terminal group and an insulating body, wherein the metal medium plate is provided with a main body portion, the first terminal group and the second terminal group are respectively located at the upper side and the lower side of the metal medium plate in a symmetrical manner, and the first terminal group, the second terminal group and the metal medium plate are molded into an integral whole by the insulating body. The first terminal group and the second terminal group respectively comprise two first grounding terminals, two second grounding terminals, a plurality of first signal terminals, two first power supply terminals, a plurality of second signal terminals and two second power supply terminals, wherein the two first grounding terminals and the two second grounding terminals are located at the outmost side, the plurality of first signal terminals and the two first power supply terminals are located between the two first grounding terminals, the plurality of second signal terminals and the two second power supply terminals are located between the two second grounding terminals, the thickness of the first power supply terminals and the second power supply terminals is greater than the thickness of the first signal terminals and the second signal terminals, and the main body portion of the metal medium plate is provided with strip-shaped holes at the positions corresponding to the first power supply terminals and the second power supply terminals. The high-current USB Type C socket can effectively support high-current charging.

Owner:SHENZHEN EVERWIN PRECISION TECH

Large-current USB Type C type socket and manufacturing method thereof

ActiveCN106252932AAvoid short circuit problemsLower impedanceContact member manufacturingContact member assembly/disassemblyUSB

Provided is a large-current USB Type C type socket, which comprises a metal middle plate provided with a main body portion; a first terminal group and a second terminal group, which are symmetrically arranged at the upper and lower sides of the metal middle plate; and an insulation body for enabling the first and second terminal groups to be integrated with the metal middle plate. The first terminal group comprises two outermost first grounding terminals, a plurality of first signal terminals, which are arranged between the two first grounding terminals, and two first power terminals; and a second terminal group comprises two outermost second grounding terminals, a plurality of second signal terminals, which are arranged between the two second grounding terminals, and two second power terminals. The thickness of the first power terminal and the thickness of the second power terminal are larger than the thickness of the first signal terminal and the thickness of the second signal terminal respectively; the main body portion of the metal middle plate is provided with strip holes in the positions corresponding to the first power terminals and the second power terminals respectively. The large-current USB Type C type socket can effectively support large-current charging.

Owner:SHENZHEN EVERWIN PRECISION TECH

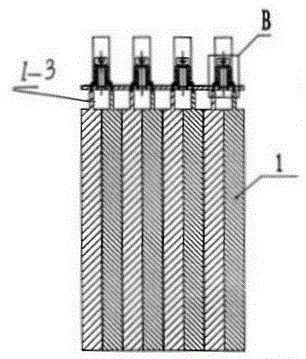

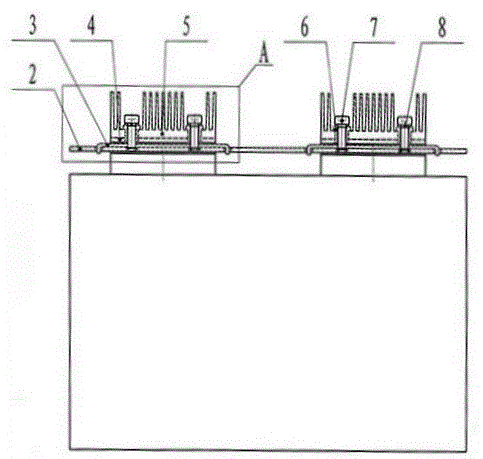

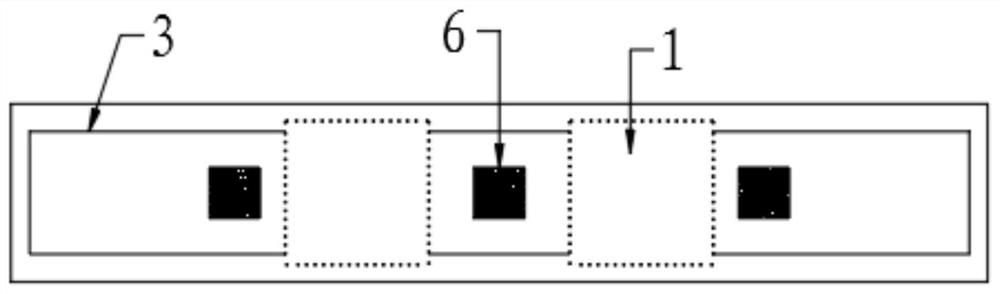

Heat dissipation structure of flexible package lithium ion battery pack

InactiveCN105680118AReduce the effect of temperature riseReduce volumeSecondary cellsBatteriesEngineeringHeat sink

The invention discloses a heat dissipation structure of a flexible package lithium ion battery pack. The heat dissipation structure comprises a lithium ion battery positive tab and a lithium ion battery negative tab, wherein a U-shaped long hole is respectively formed in the flexible package lithium ion battery positive tab and the flexible package lithium ion battery negative tab; a PCB fixed plate is arranged above the U-shaped long holes; a fixed supporting plate is provided with a fixed claw which is firmly combined with the PCB fixed plate to form a rigid flat supporting surface; a circular hole for assembling a heat conduction silicone strip is formed in the flat supporting surface of the PCB fixed plate; a cooling fin is arranged on the heat conduction silicone strip; and assembling holes formed in the fixed supporting plate, the heat conduction silicone plate and the cooling fin are concentric, and the fixed supporting plate, the heat conduction silicone plate and the cooling fin are compressed by utilizing screws by virtue of an insulation sleeve and a spring gasket installed on the insulation sleeve so as to be fixed to the positive and negative tabs of a battery cell. The heat dissipation structure of the flexible package lithium ion battery pack is small in size and light in weight; and the aluminum cooling fin can take away a given amount of heat produced by the battery, and thus a good effect of lowering the temperature of the battery pack is achieved.

Owner:河南环宇赛尔新能源科技有限公司

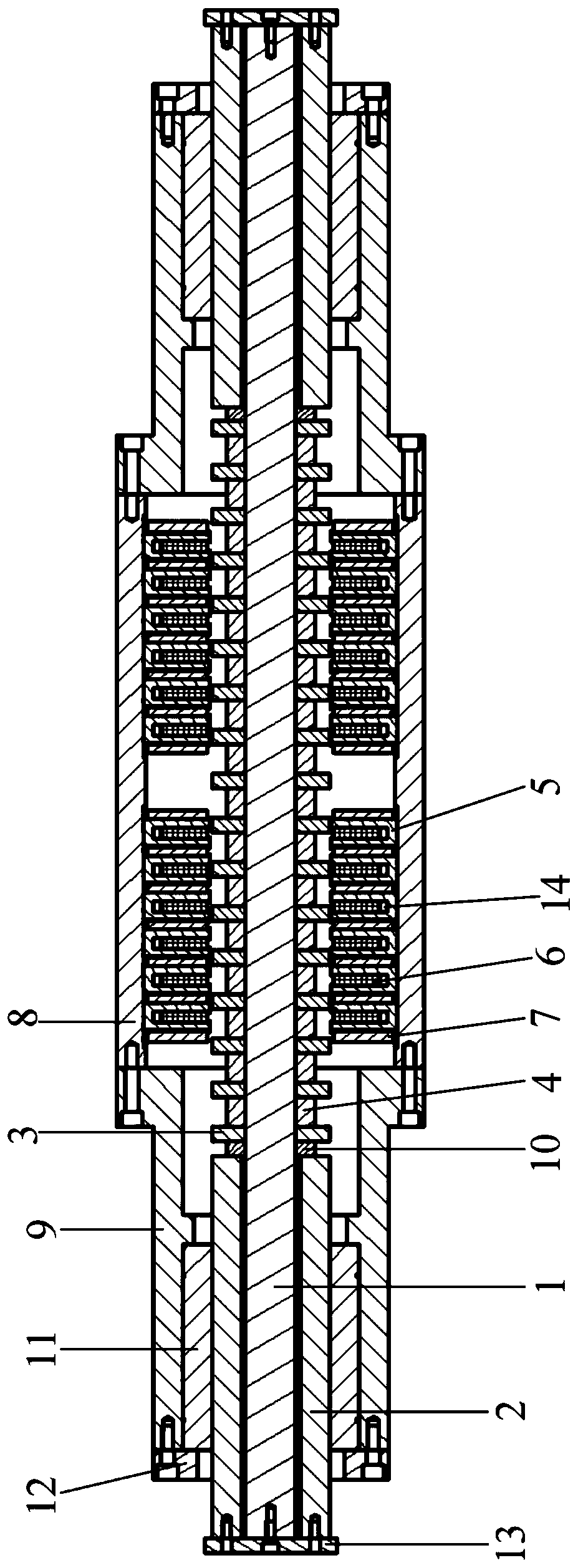

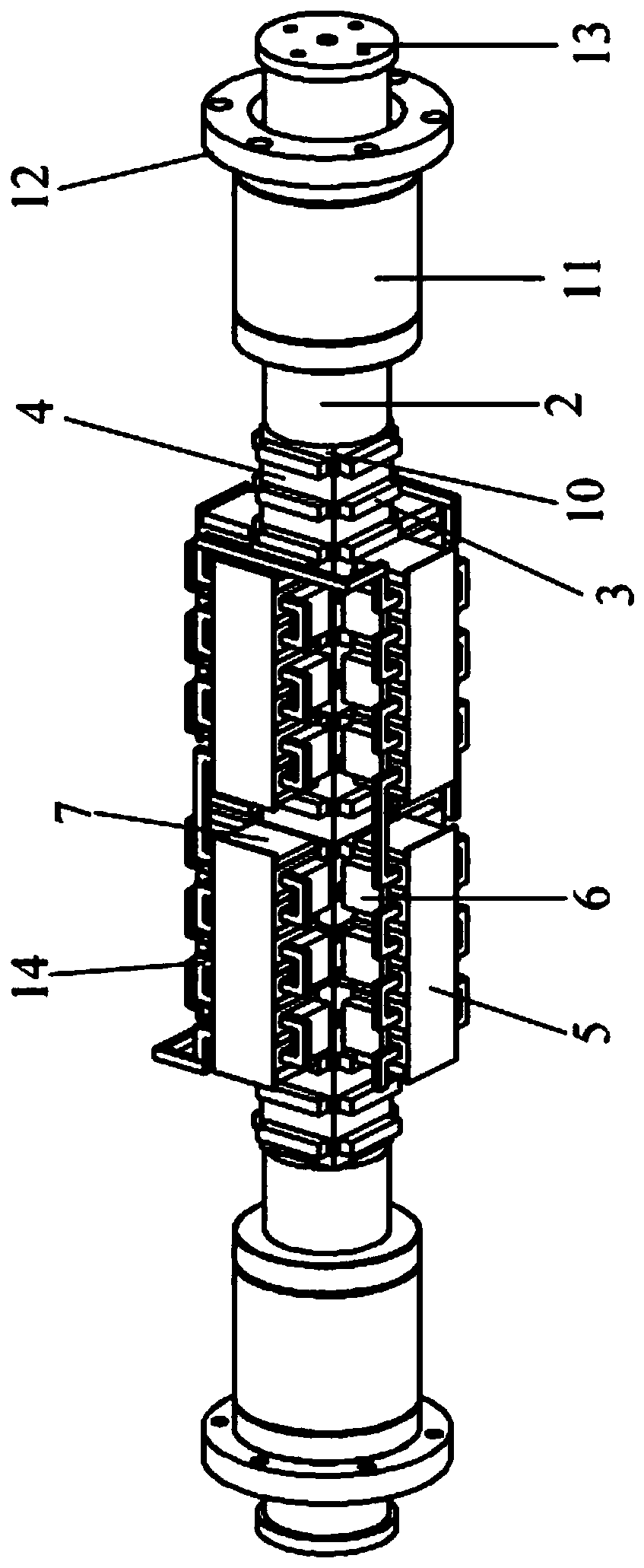

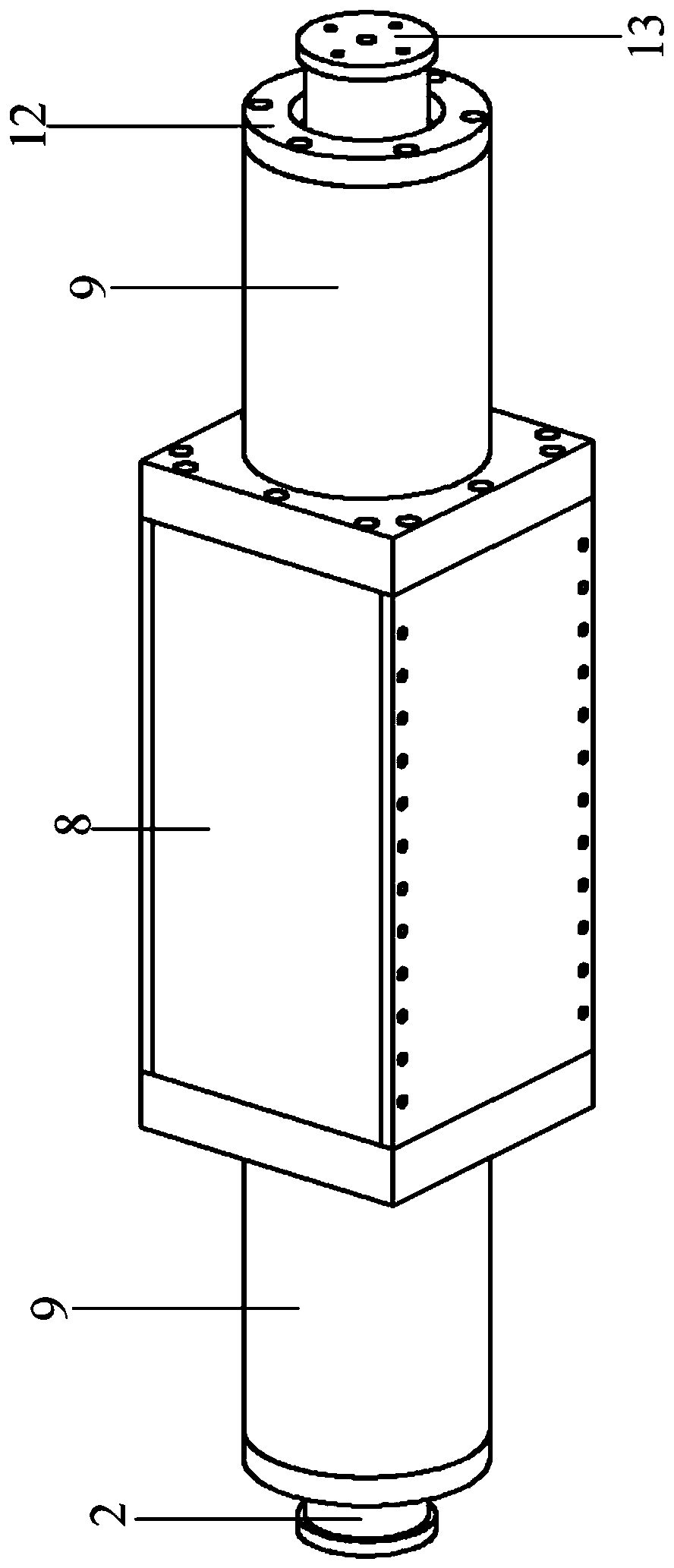

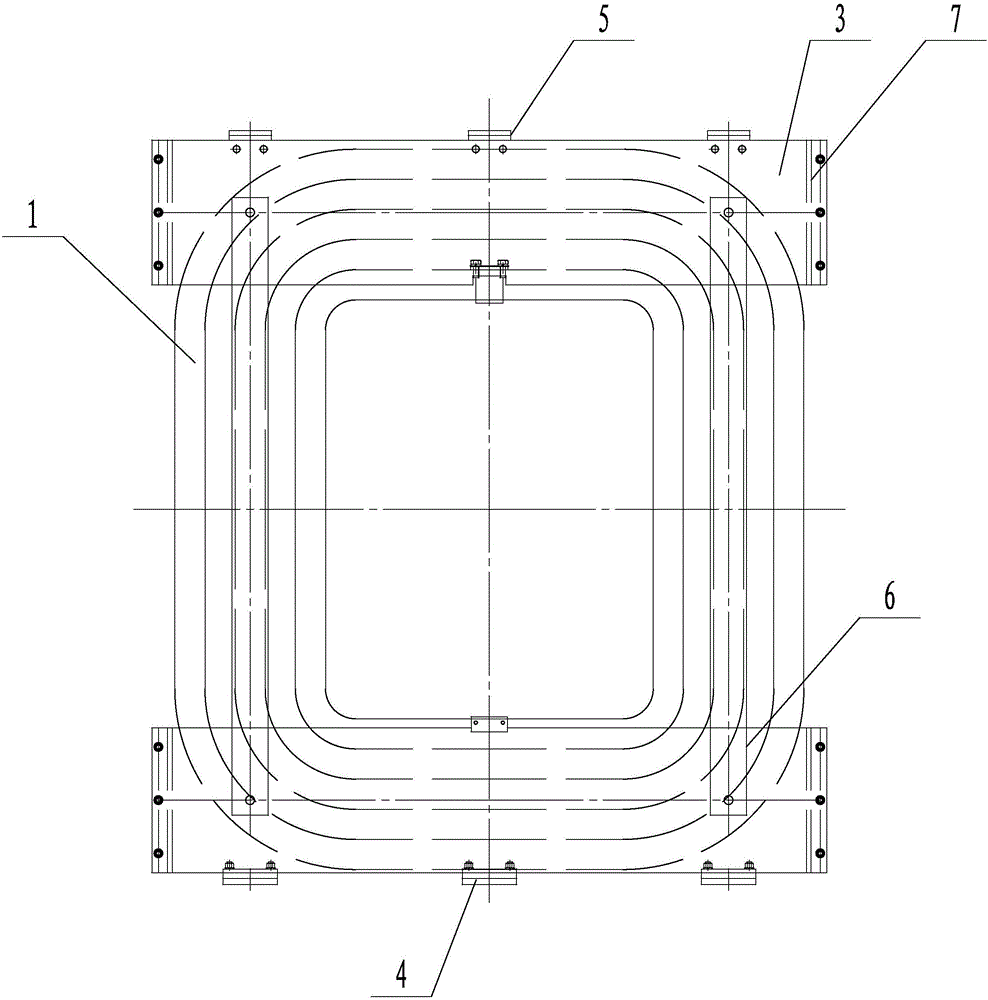

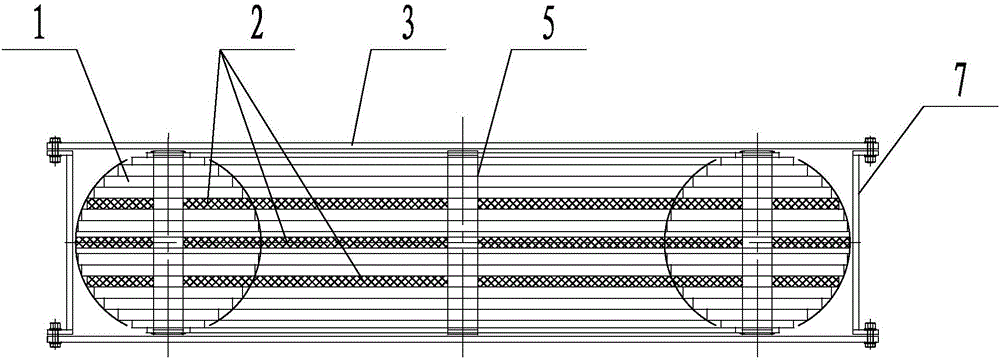

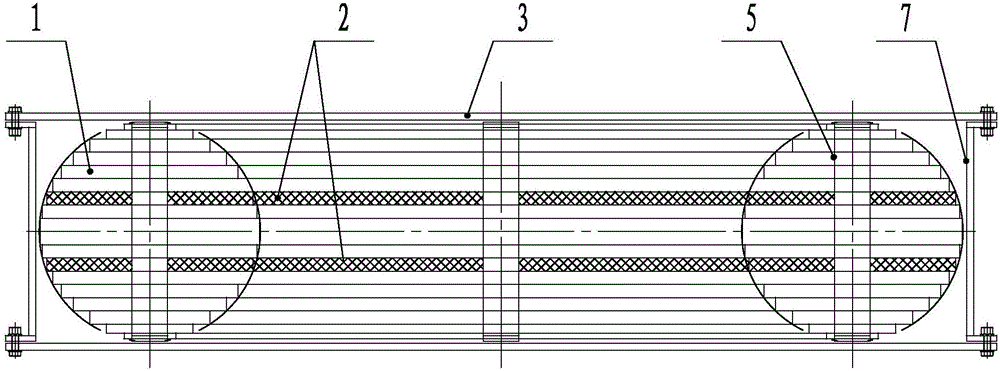

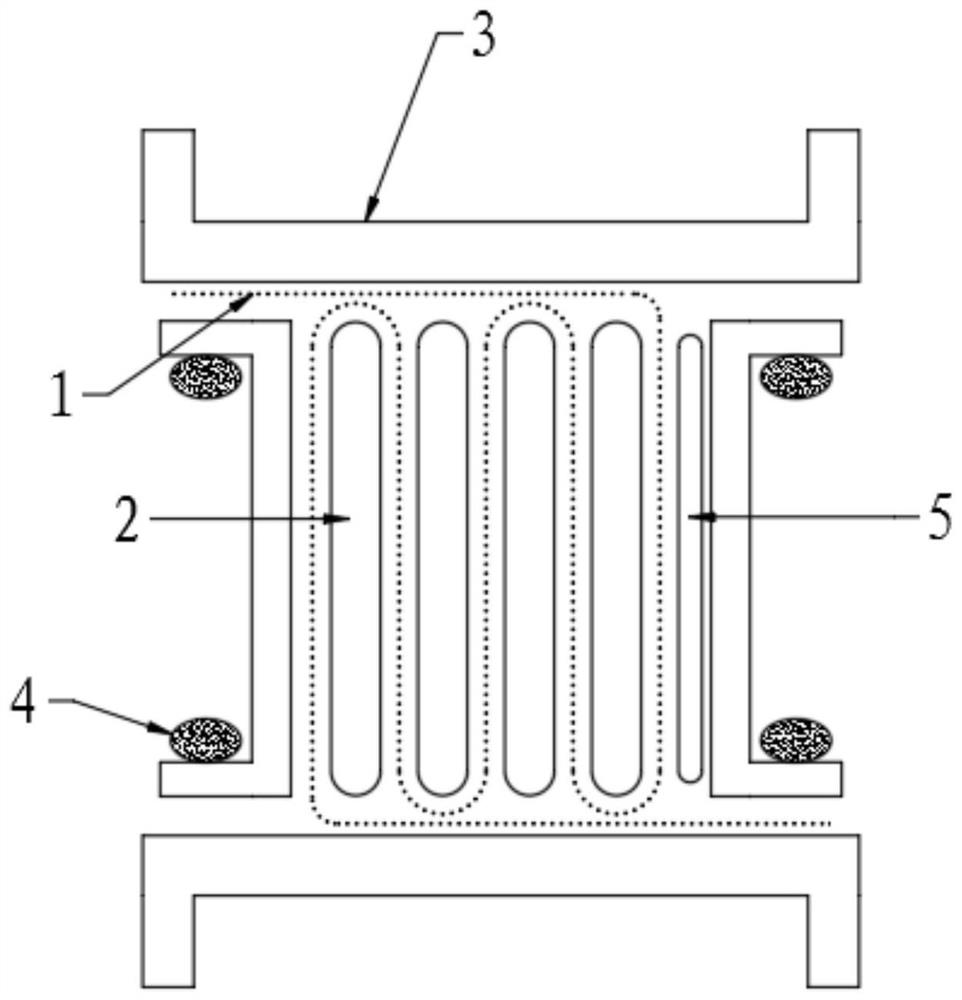

Primary permanent magnet linear motor actuator

InactiveCN109787448AReduce the effect of temperature riseImprove power densityMagnetic circuit stationary partsCooling/ventillation arrangementPrimary permanentDrive shaft

The invention discloses a primary permanent magnet linear motor actuator. The primary permanent magnet linear motor actuator comprises a driving shaft, a secondary mover convex tooth block, a secondary mover channel block, primary stator iron cores, an armature winding and a permanent magnet body, wherein a secondary mover of a primary permanent magnet linear motor is arranged on a driving shaft and consists of the secondary mover convex tooth block and the secondary mover channel block arranged in the axial direction of the driving shaft at intervals; four primary stators of the primary permanent magnet linear motor are separately and symmetrically arranged on the outer side of the driving shaft; each of the primary stator comprises two primary stator iron cores; each of the primary stator iron cores is provided with a plurality of stator channels; each of the stator channel comprises a large stator channel and a small stator channel; and the large stator channels and the small statorchannels are arranged at intervals. Through creative proposal of a four-sided tubular structure, the pushing force density and the power density of the actuator can be improved, so that the driving shaft of the actuator has a simple structure and is high in robustness; and through arrangement of a built-in water cooling pipeline, the heating effect is reduced.

Owner:XIDIAN UNIV

Large-current USB Type C socket

ActiveCN106252933AAvoid short circuit problemsLower impedanceCoupling contact membersCoupling protective earth/shielding arrangementsUSB

A large-current USB Type C socket comprises a metal medium plate which is provided with a body part, a first terminal group and a second terminal group which are respectively arranged at the upper and lower sides of the metal medium plate and are symmetrical, and an insulating body which integrally molds the first and second terminal groups and the metal medium plate. The first and second terminal groups comprise two first grounding terminals and two second grounding terminals at the outmost side, a plurality of first signal terminals and two first power terminals between the two first grounding terminals, and a plurality of second signal terminals and two second power terminals between the two second grounding terminals, wherein the first and second power terminals are thicker than the first and second signal terminals. The metal medium plate is provided with strip holes in positions corresponding to the first and second power terminals. The large-current USB Type C socket of the application can effectively support large-current charging.

Owner:SHENZHEN EVERWIN PRECISION TECH

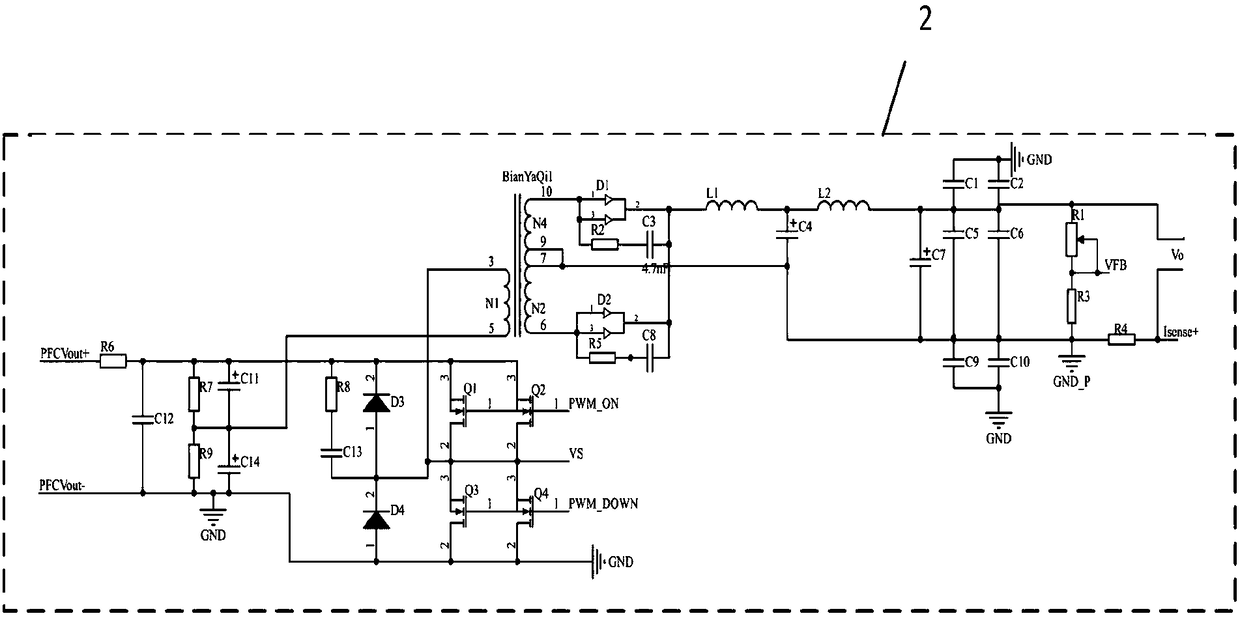

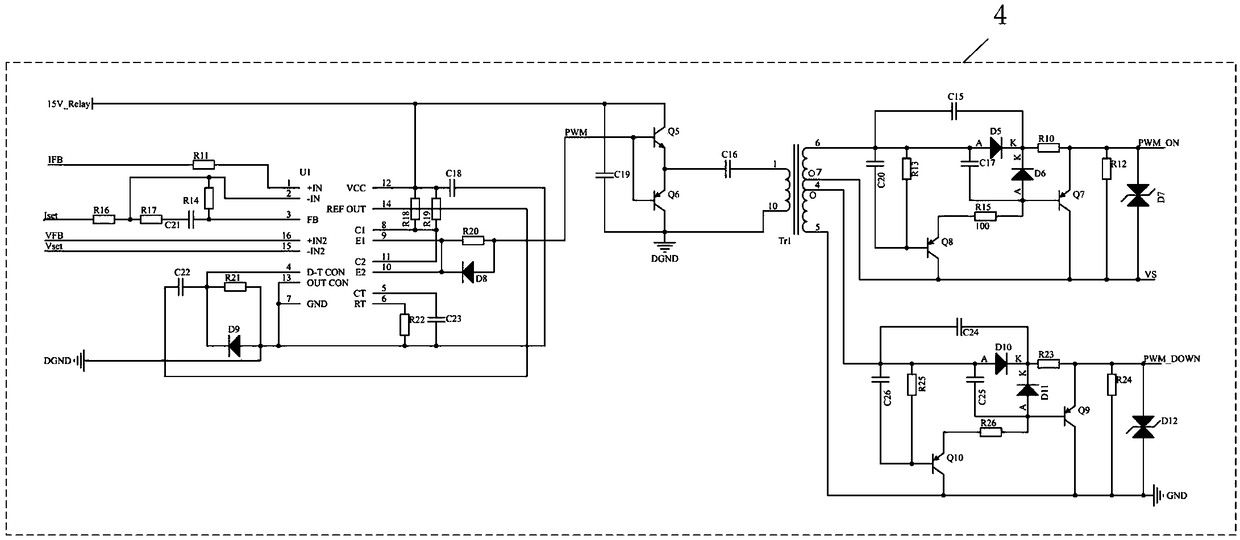

High-precision laser remote sensing numerical control power supply circuit

ActiveCN108123624AEasy to adjust controlReliable PWM waveEfficient power electronics conversionAc-dc conversionNumerical controlTransformer

The invention discloses a high-precision laser remote sensing numerical control power supply circuit, which comprises a BOOST PFC module, a chip isolation power supply module, a main circuit step-downmodule, an MOS driving module, a control module and a sampling module. Optimization and improvement are performed on a secondary driving MOS circuit of transformer isolation drive, so that the designof the transformer isolation driving circuit module can achieve low power consumption and no negative voltage and has a driving waveform with a fast rising edge and falling edge. When the system adopts a high switch operating frequency of 100KHz, the transformer isolation driving circuit module can still obtain a high driving MOS capability and acquire an effect of low temperature rise. The circuit adopts a full-isolation circuit design, the damages for a laser are effectively reduced when the power supply breaks down, a wide operating range is outputted, the disturbance of sampled signals iseffectively reduced, safe isolation between high voltage of a main circuit and low power supply voltage of a chip is achieved, the chip is effectively protected, and the miniaturization of the wholemachine is realized.

Owner:BEIJING UNIV OF TECH

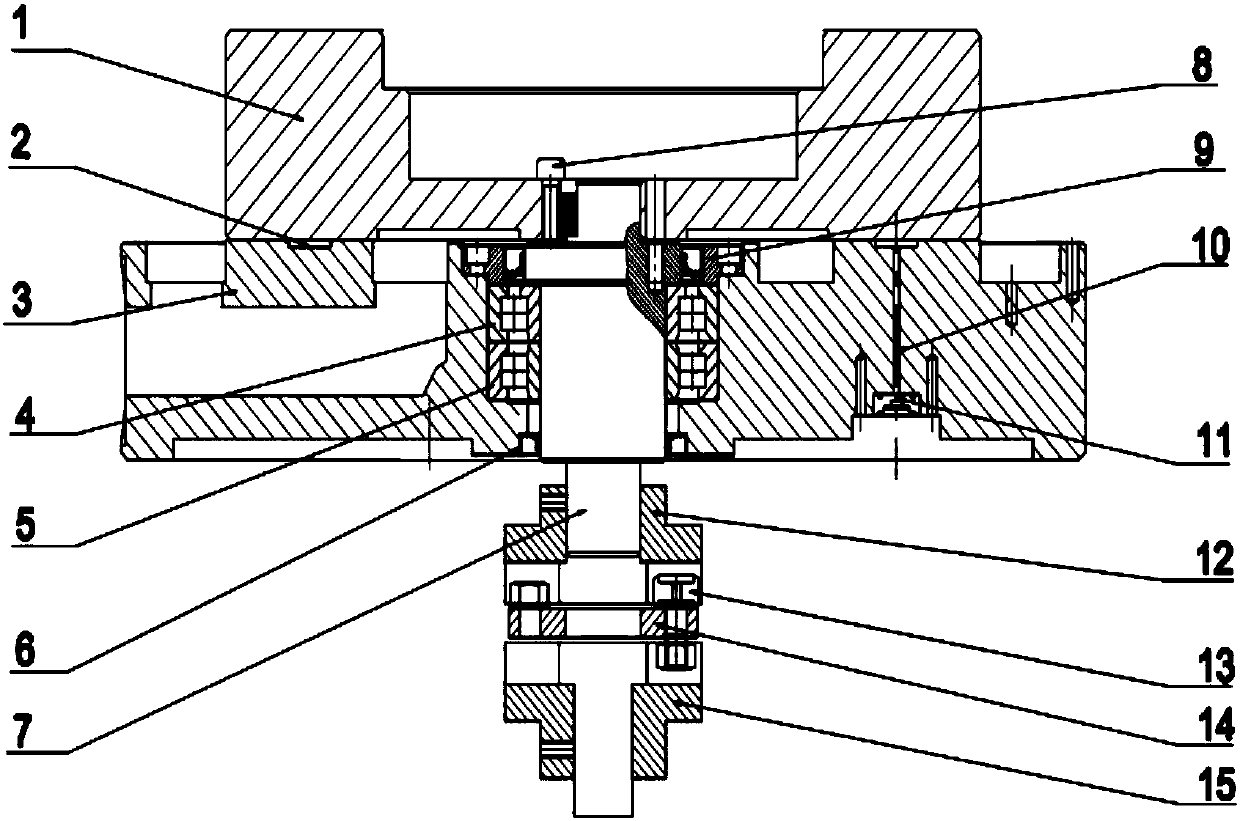

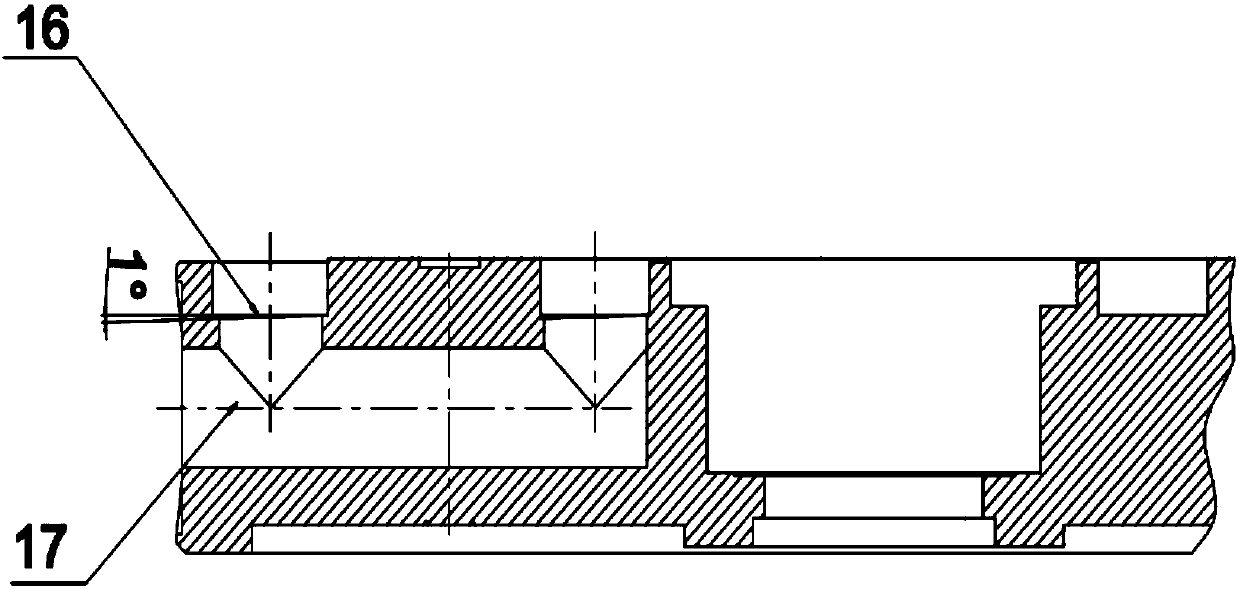

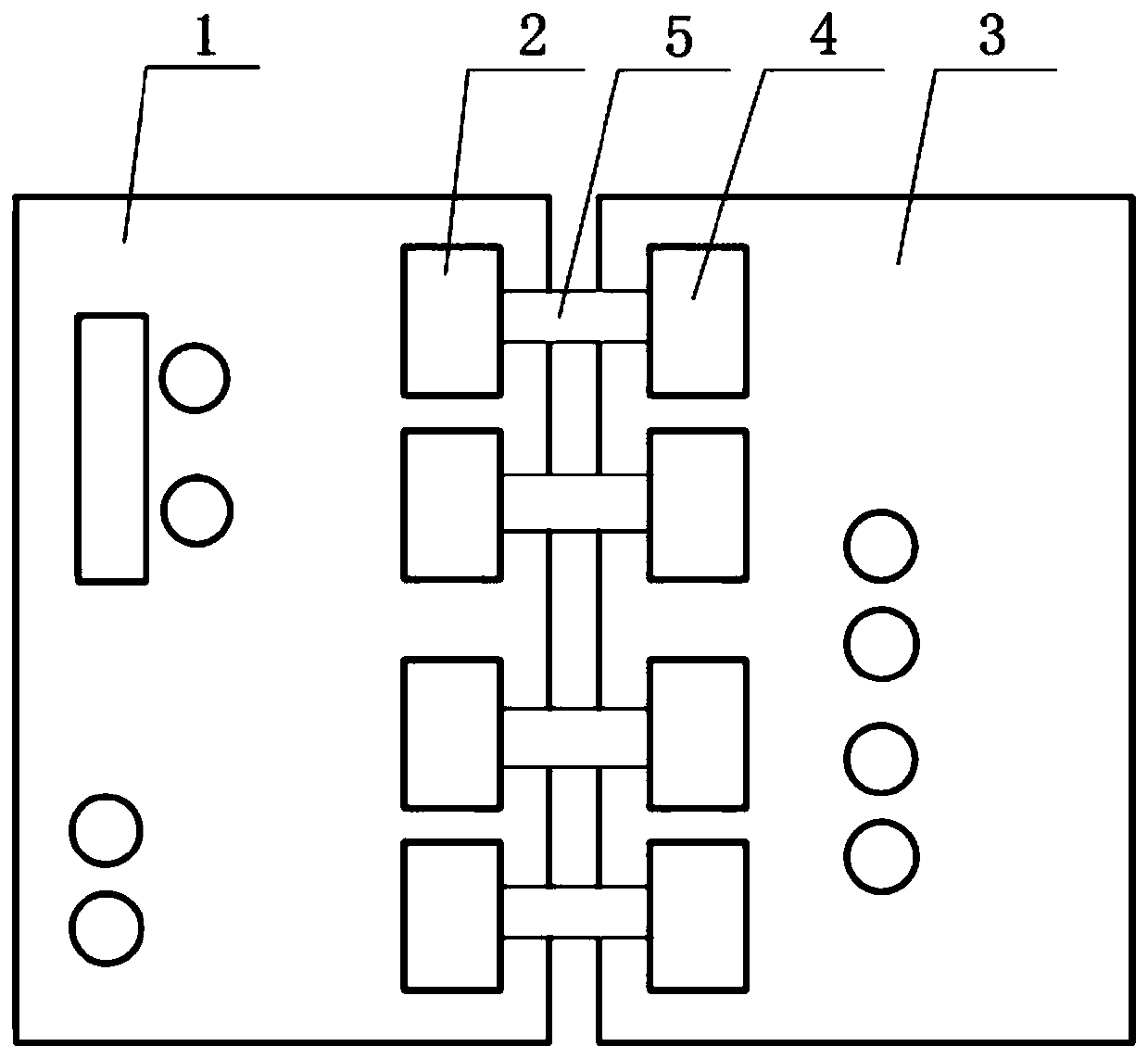

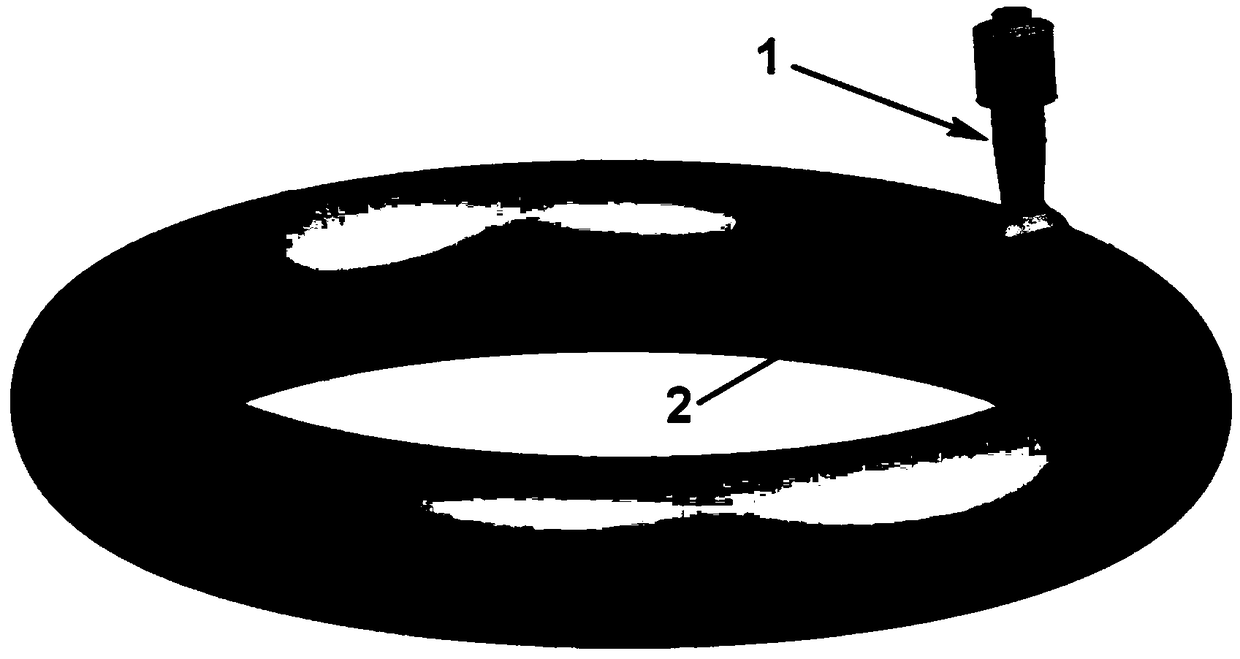

Novel hydrostatic pressure thrust bearing device

ActiveCN110230642AEliminate misalignment errorsGuaranteed rotation accuracyLiquid cushion bearingsCouplingThrust bearing

The invention belongs to the field of bearings, and particularly discloses a novel hydrostatic pressure thrust bearing device. The novel hydrostatic pressure thrust bearing device comprises a rotary workbench, a thrust bearing and a main shaft mechanism, wherein the rotary workbench is horizontally arranged on the upper surface of the thrust bearing and fixedly connected with a main shaft; the thrust bearing is provided with an annular oil cavity, an oil return groove, an oil supply hole which is in communication with the annular oil cavity, and an oil return hole which is in communication with the oil return groove; the main shaft mechanism comprises the main shaft and a cross rolling coupling; the main shaft penetrates the thrust bearing and is matched with the thrust bearing through twoparallel cylindrical roller bearings; the upper end of the main shaft is connected with the rotary workbench, and the lower end of the main shaft is connected with the cross rolling coupling; the cross rolling coupling comprises an upper transmission seat, a lower transmission seat and a transmission disc positioned between the upper transmission seat and the lower transmission seat; and the transmission disc is in sliding fit with the upper transmission seat and the lower transmission seat through four roller cam guide apparatuses which are distributed on the upper surface and the lower surface of the transmission disc in a cross manner. The novel hydrostatic pressure thrust bearing device has the advantages of being high in rotation precision, small in friction coefficient and good in stability.

Owner:HUAZHONG UNIV OF SCI & TECH

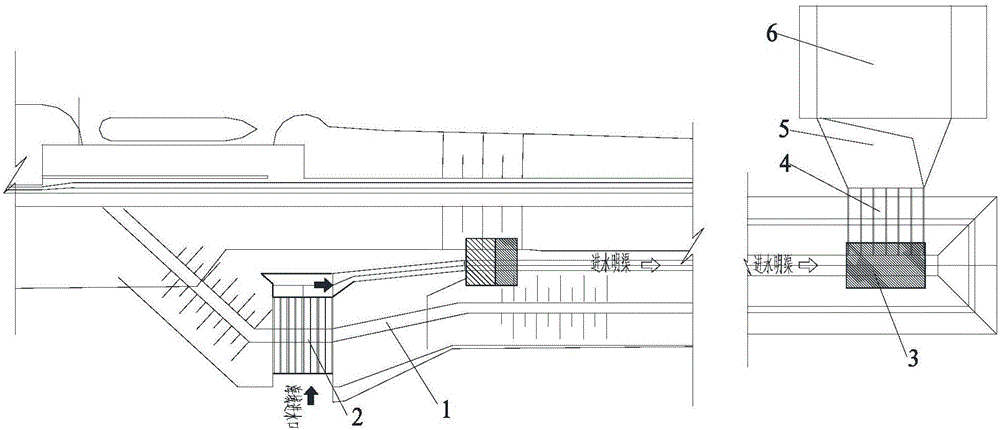

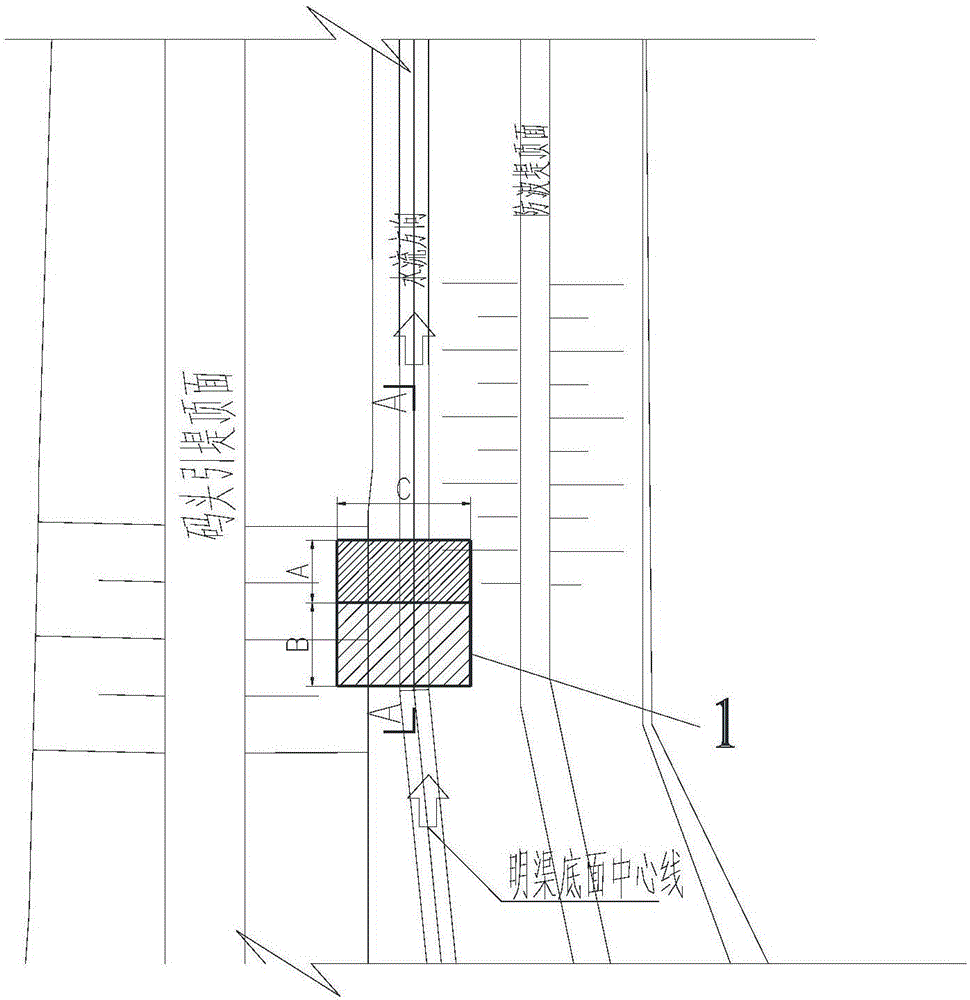

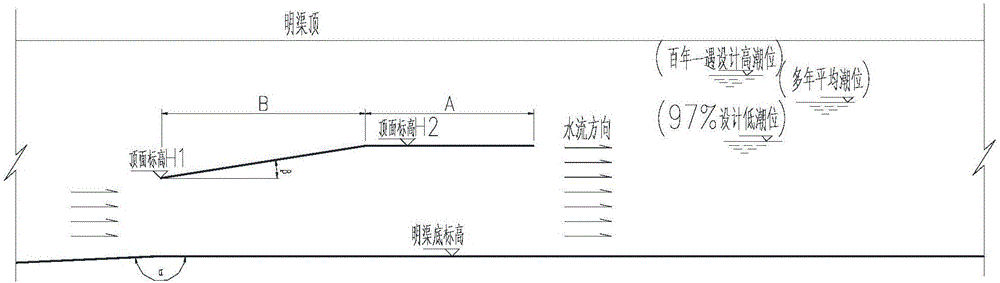

Electric power plant water diversion open ditch flow guide heat insulation device and design method thereof

ActiveCN106227980AObvious stratificationWater flow rate is smallGeometric CADDesign optimisation/simulationEconomic benefitsEngineering

The invention discloses an electric power plant water diversion open ditch flow guide heat insulation device and a design method thereof. The device comprises a folded plate type flow guide plate and a flat plate type flow guide plate, wherein the folded plate type flow guide plate comprises a first inclined plate and a first flat plate; one end of the first inclined plate is arranged at an entrance position of an open ditch; the other end of the first inclined plate is connected with the first flat plate; the side edge of the first inclined plate and the side edge of the first flat plate are fixed on the side wall of the water diversion open ditch; the flat plate type flow guide plate is arranged in a connecting position of an exit of the open ditch and a water inlet rectifier box, and comprises a second flat plate; the side edge of the second flat plate is fixed on the side wall of the water diversion open ditch. According to the design method provided by the invention, the design parameters of the current water diversion open ditch and rectifier box culvert and the like is obtained; hydromechanics software is used for building the open ditch flow state of the device provided by the invention; the value calculation optimization is further performed to achieve the goal. The electric power plant water diversion open ditch flow guide heat insulation device and the design method have the advantages that the temperature rise influence of sun radiation on the water body in the water diversion open ditch conveying process can be effectively reduced; the cooling water taking temperature of an electric power plant is reduced; the efficiency of a power generating set is improved; high economic benefits and application popularization values are realized.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

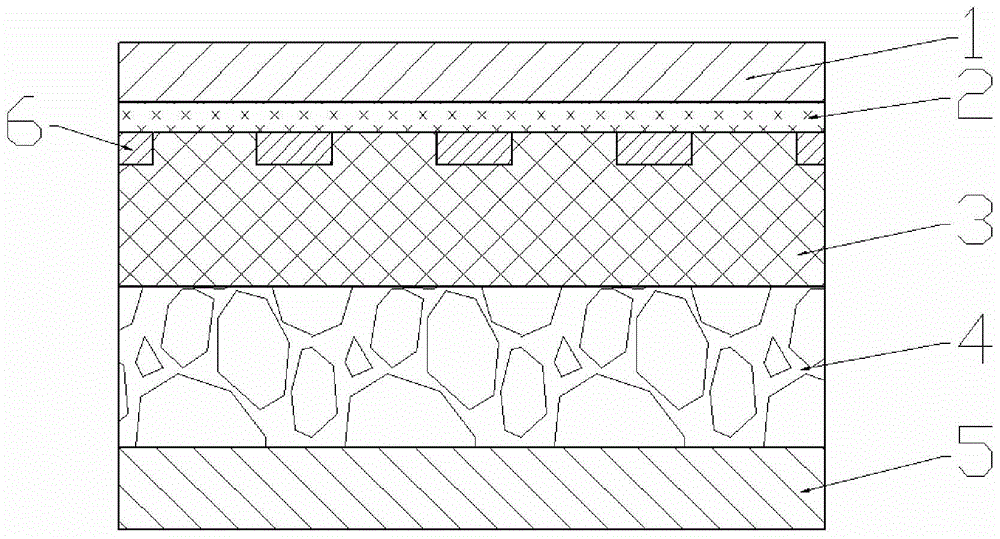

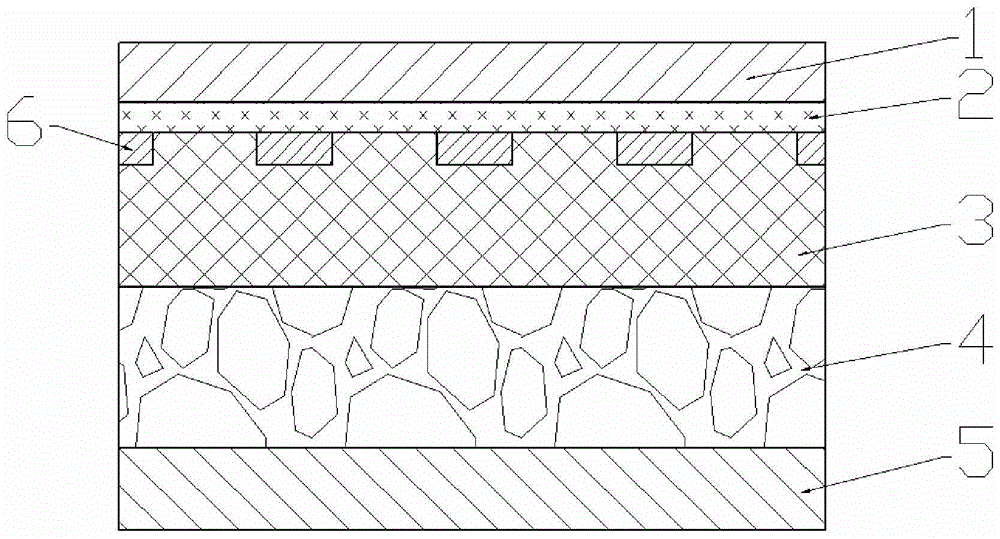

Anti-slip and anti-wear PVC composite floor with high-transmittance surface structure

ActiveCN104947914AHigh light transmittanceImprove toughnessSynthetic resin layered productsCoatingsFiberCarbon fibers

The invention discloses an anti-slip and anti-wear PVC composite floor with a high-transmittance surface structure. The PVC composite floor includes a PVC panel and a bottom glue layer, wherein a waterproof insulating layer is arranged between the PVC panel and the bottom glue layer; the upper surface of the PVC panel is covered with a high-density anti-wear layer; the upper surface of the high-density anti-wear layer is coated with a high-transmittance surface layer; grooves are formed in the upper surface of the PVC panel; carbon fiber strips are arranged in the grooves. The PVC composite floor designed by the invention is firm and durable, simple in laying, anti-slip and anti-wear, and long in service life.

Owner:JIANGSU RUISHENG NEW MATERIALS CO LTD

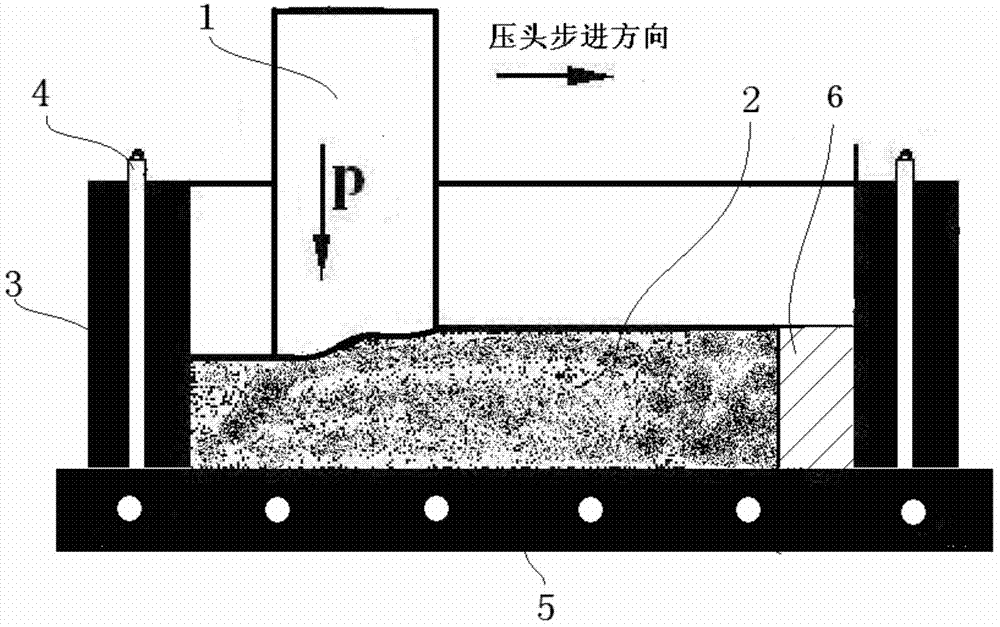

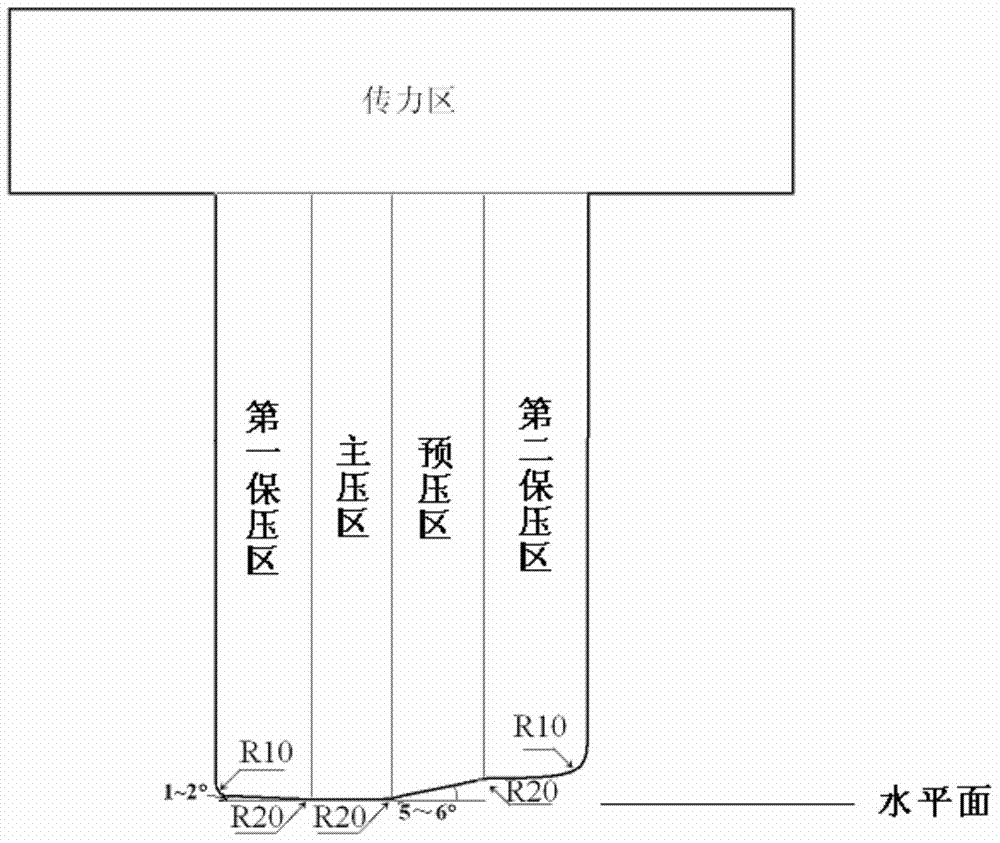

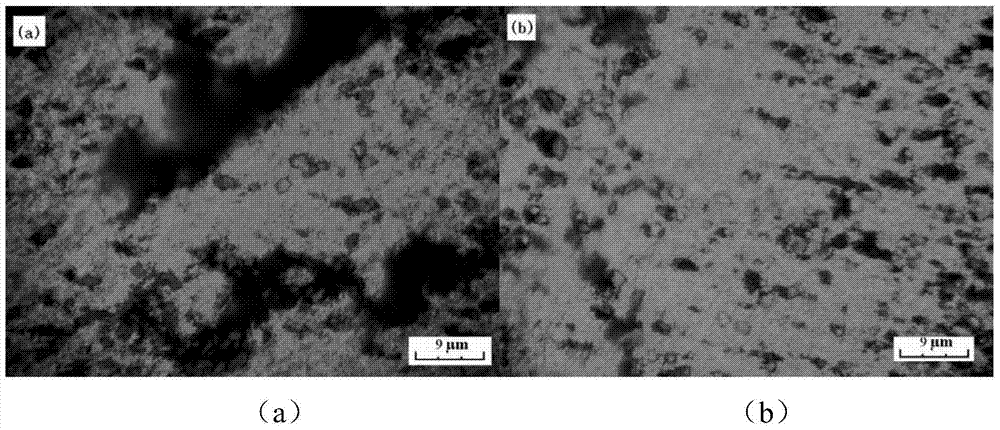

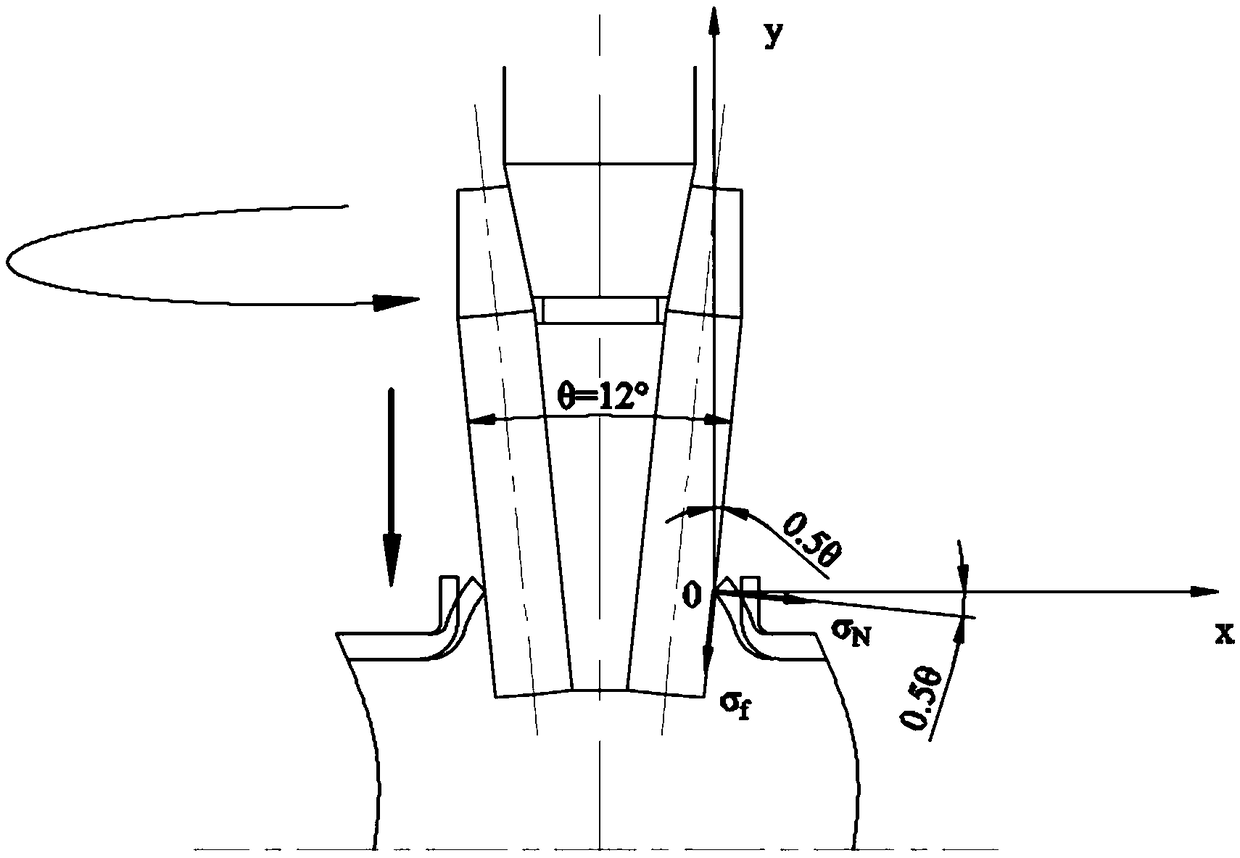

Pressing head and device for achieving densification of spray deposition porous panel and application thereof

Owner:HUAIHAI INST OF TECH

Energy-saving gas stove

InactiveCN103939951AHigh thermal efficiencyReduce lossesDomestic stoves or rangesLighting and heating apparatusConservation energyProcess engineering

The invention discloses an energy-saving gas stove, which comprises a burner, a gas stove panel, a bracket and an energy saving ring. The energy-saving gas stove is characterized in that the burner is arranged in a burner installing hole formed in the gas stove panel; a bracket for supporting cookware is mounted above the gas stove panel; the annular energy saving ring is arranged at the inner ring of the bracket; the height of the energy saving ring is less than that of the bracket, so that the cookware can be smoothly placed on or taken out of the bracket; a certain space is remained between the energy saving ring and the bottom surface of a wok, so that the gas can be sufficiently combusted. According to the energy-saving gas stove, a ring body with annular structure is made of thermal resistant and insulating material, so that the heat energy loss caused by heat radiation of the gas stove flame and heat dissipation of air convection is greatly reduced, the heat efficiency is remarkably increased and the energy is saved.

Owner:CHENGDU ZHONGCHENG TECH

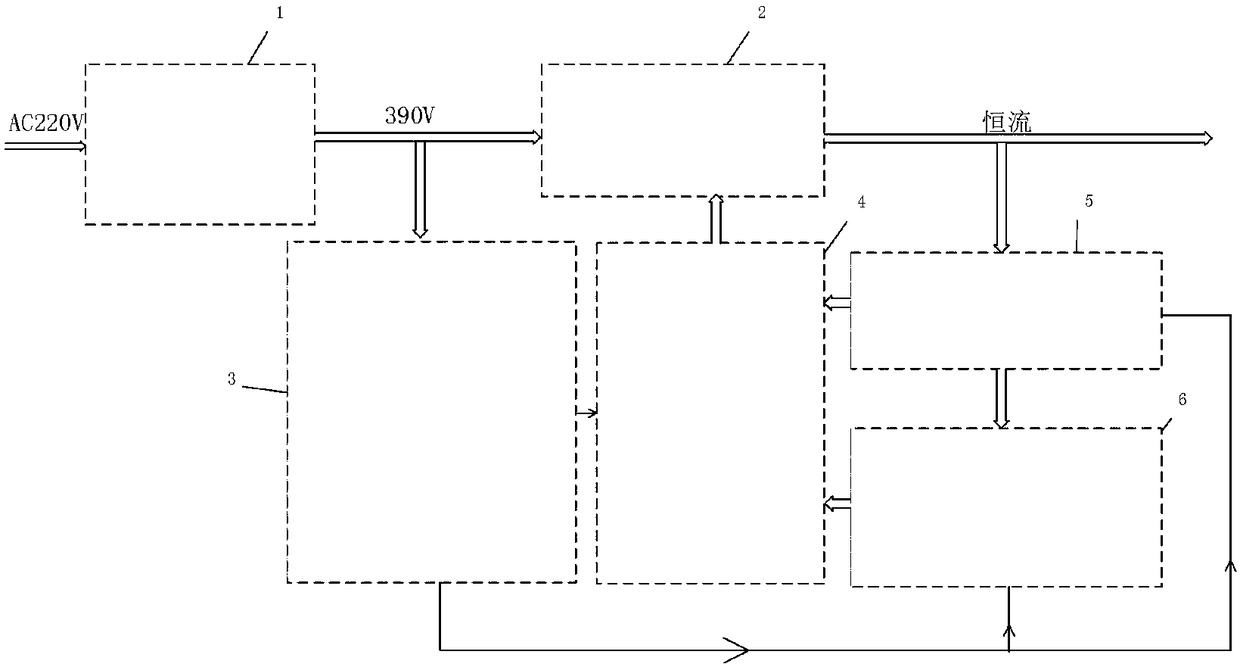

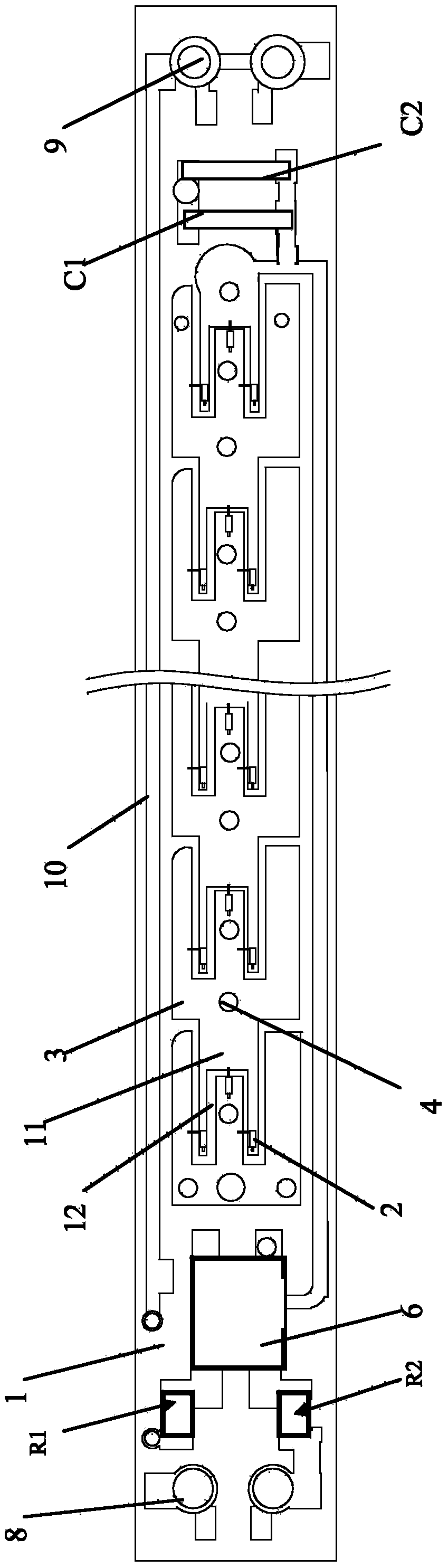

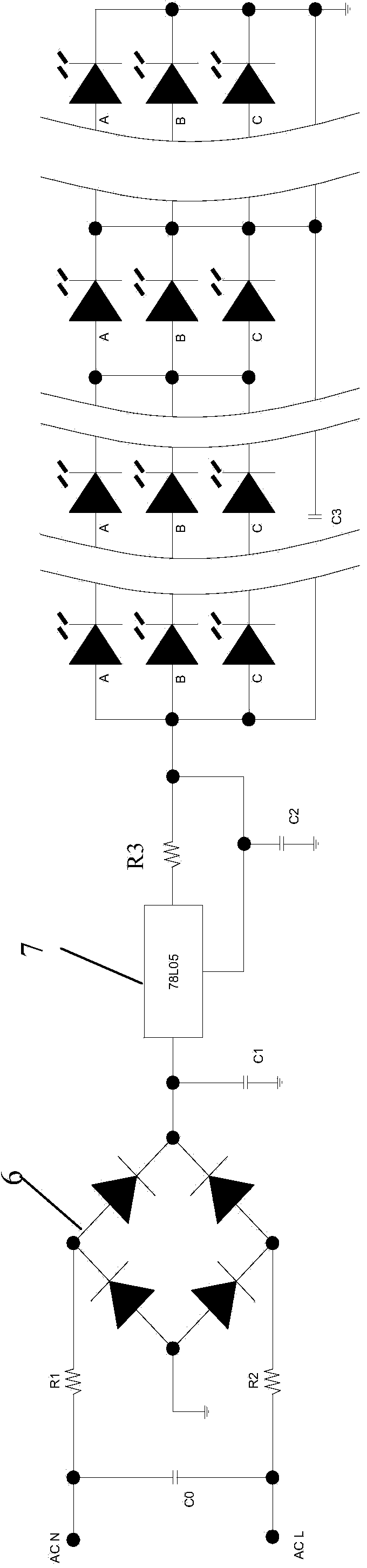

High-voltage constant-current drive circuit and LED light source with same

InactiveCN103517523AEasy size adjustmentSelf working current is smallPoint-like light sourceElectric circuit arrangementsEngineeringAlternating current

The invention discloses a high-voltage constant-current drive circuit which comprises a rectifier module and a constant-current module. The constant-current module is a stabilized voltage supply regulator, the input end of the stabilized voltage supply regulator is connected with the positive electrode output of the constant-current module, and the output end of the stabilized voltage supply regulator is connected with a high-impedance load. The GND end of the stabilized voltage supply regulator is connected with a feedback resistor in series and then is connected with the output end of the stabilized voltage supply regulator. The negative electrode of an LED chip is connected with the negative electrode output of the rectifier module or is connected with the ground. Meanwhile, the invention further discloses an LED light source with the circuit. The stabilized voltage supply regulator is creatively used as a constant current controller, and controls the rectified alternating currents directly in a constant-current mode and then supplies the currents to the high-impedance load. The magnitude of the output constant currents of the output can be conveniently regulated through changing of the feedback resistor, the structure is concise, cost is low, and market competitiveness is effectively improved.

Owner:TIANJIN JINMA PHOTOELECTRIC

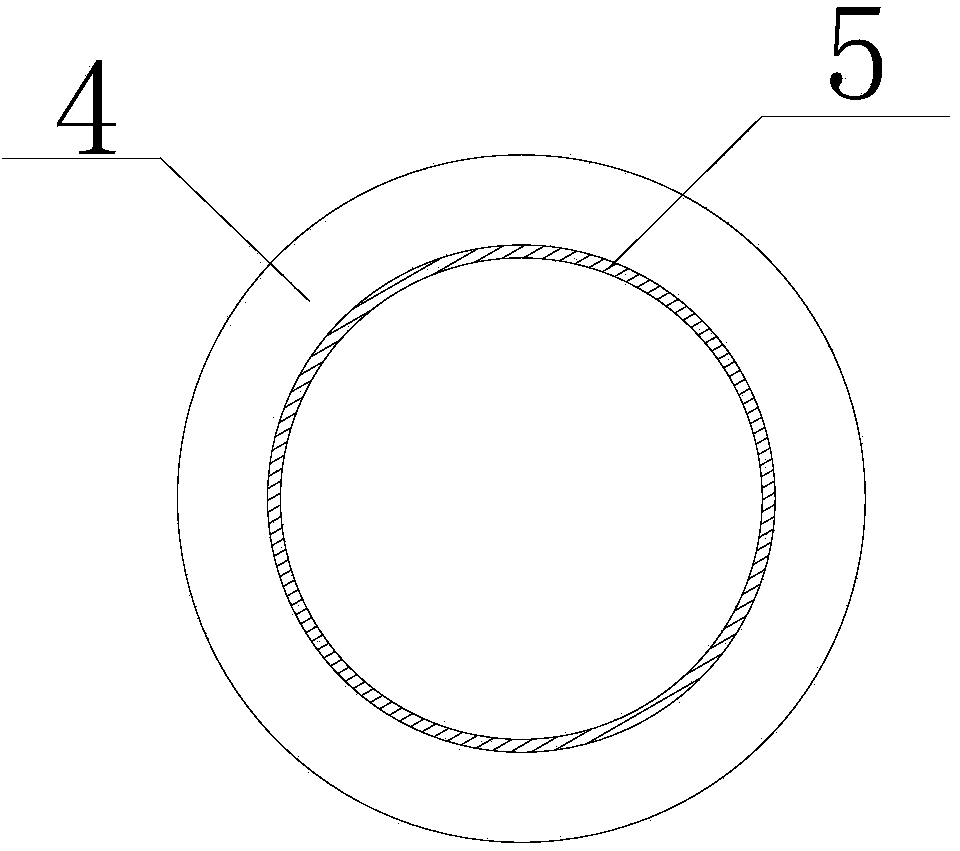

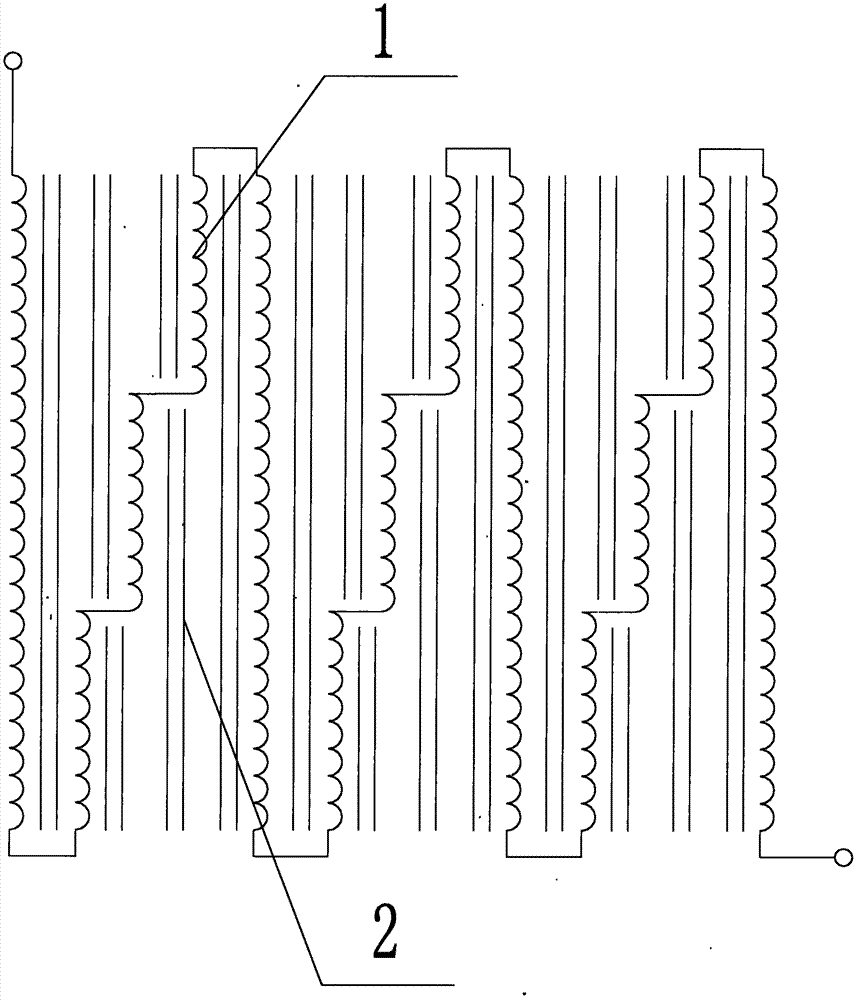

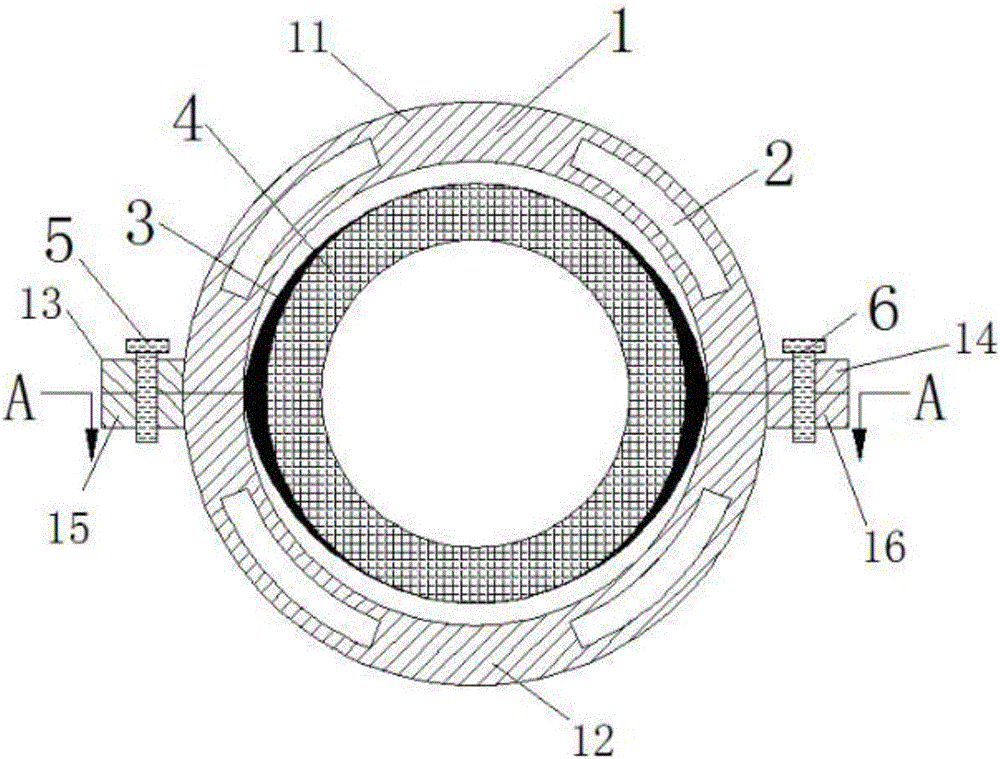

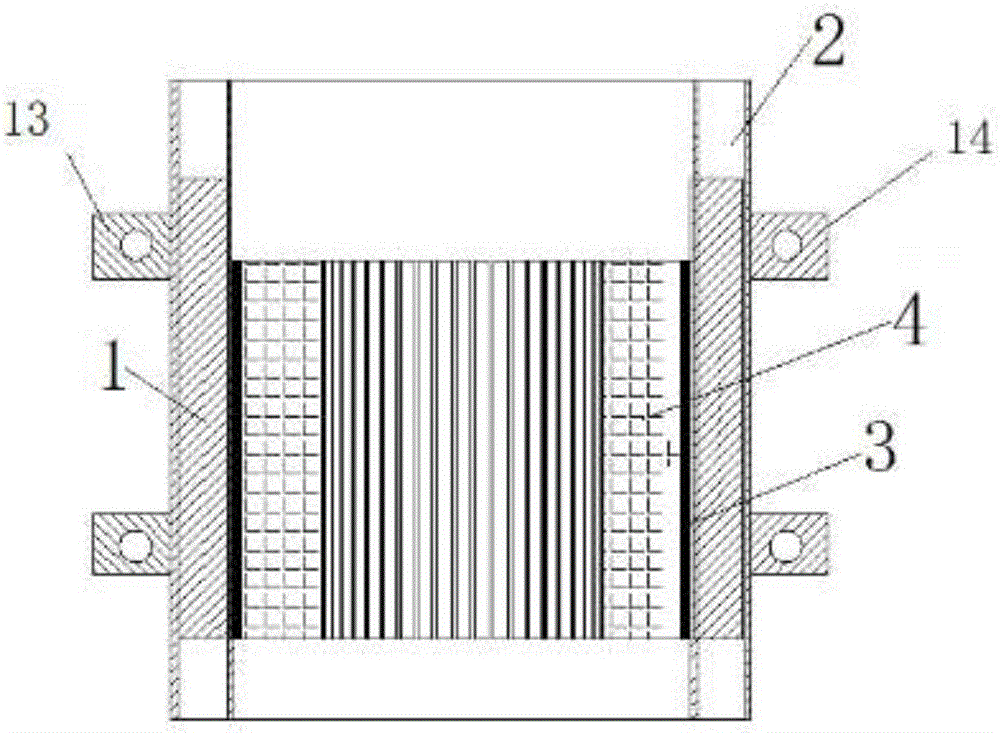

Iron core structure of reel iron core transformer

InactiveCN106449045AReduce the effect of temperature riseReduce manufacturing difficultyTransformers/inductances coolingTransformers/inductances magnetic coresTransformerCooling effect

The invention relates to an iron core structure of a reel iron core transformer. At present, when the diameter of an iron core is greater than 640mm, more oil channels need to be placed, and vertical oil channels are required in necessary, so that a complex structure and non-ideal heat dissipation are caused. The iron core structure provided by the invention comprises an iron core body which is formed by multiple layers of closed reel iron core laminated sheets in a laminated manner, and iron core oil channels formed in the iron core body; the iron core structure is characterized in that multiple iron core oil channel layers are arranged on the iron core body in the laminating direction; the iron core body is divided by the iron core oil channel layers into iron core sub bodies which are not in contact mutually; each iron core sub body is formed by multiple closed reel iron core laminated sheets in a laminated manner; and each iron core oil channel layer consists of multiple iron core coil channels in the same layer. According to the technical scheme, the multiple iron core coil channel layers are adopted to replace the closed reel iron core laminating sheets in the located layer, and the reel iron core is divided into multiple iron core sub bodies in the laminating direction, so that it is ensured that enough heat dissipation medium can enter the interior of the iron core, and a cooling effect can be played quickly and efficiently.

Owner:WOLONG ELECTRIC YINCHUAN TRANSFORMER

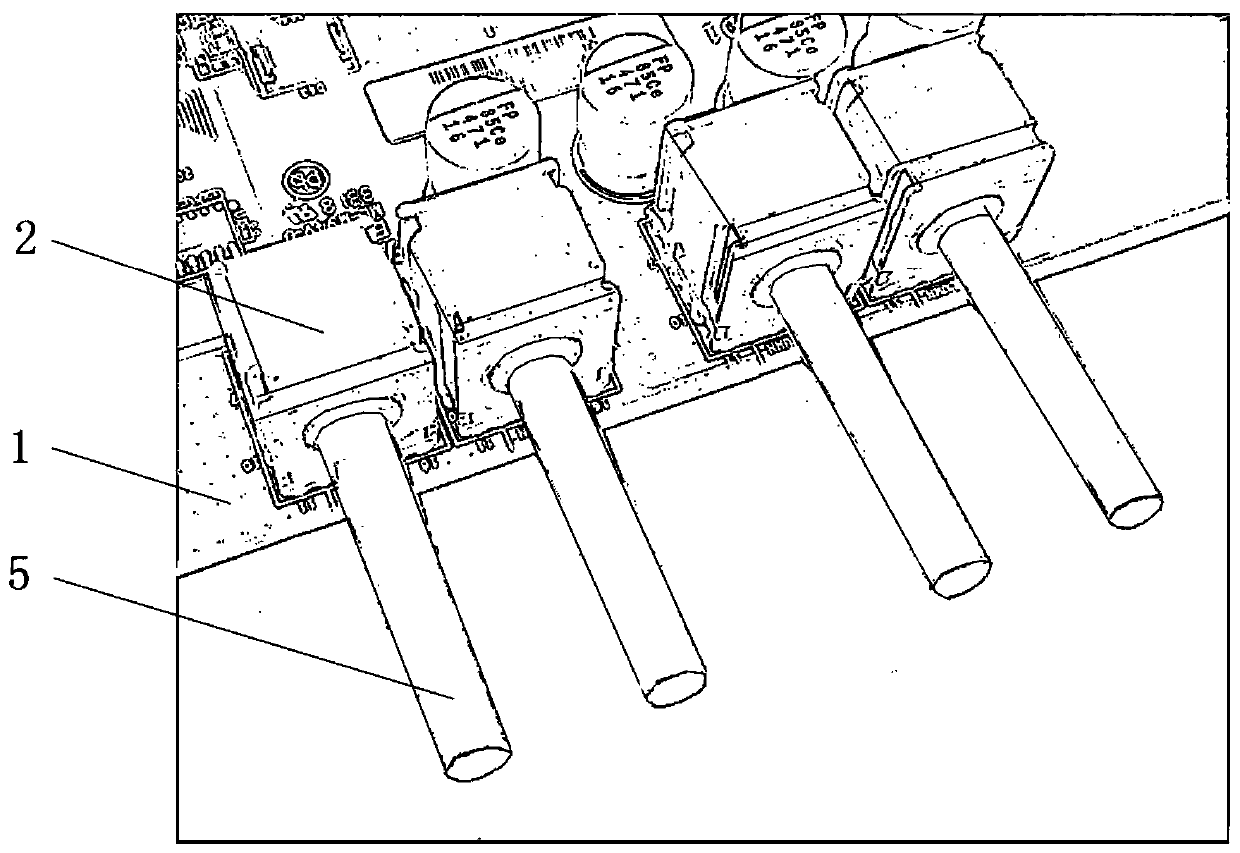

Server and high-current-resistant power supply terminal structure thereof

PendingCN109935986AIncrease the cross-sectional areaImprove the transmission performance of high current resistance power supplySecuring/insulating coupling contact membersCoupling contact membersCarrying capacityEngineering

The invention discloses a large-current-resistant power supply terminal structure of a server. The structure comprises a power supply board card, a plurality of male end terminals arranged on the power supply board card, a power receiving board card, and a plurality of female end terminals arranged on the power receiving board card. Each male end terminal is provided with a conductive column, andeach male end terminal is detachably connected with the corresponding female end terminal through the corresponding conductive column. Thus, each male end terminal and each female end terminal which correspond to each other are detachably connected through the corresponding single conductive column, so the disassembly and assembly are facilitated, the sectional area of each single conductive column can be made larger, and the current carrying capacity is higher. Meanwhile, the conductive columns are respectively distributed on the male end terminals, so the structure is dispersed and independent, the distribution density is low, the influence of temperature rise is small, and the adverse influence of sealing of the plastic shell is avoided. Therefore, the large-current-resistant power supply transmission performance of a server power supply system can be improved, and the temperature rise heat dissipation limitation is broken through. The invention also discloses the server which has the above beneficial effects.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

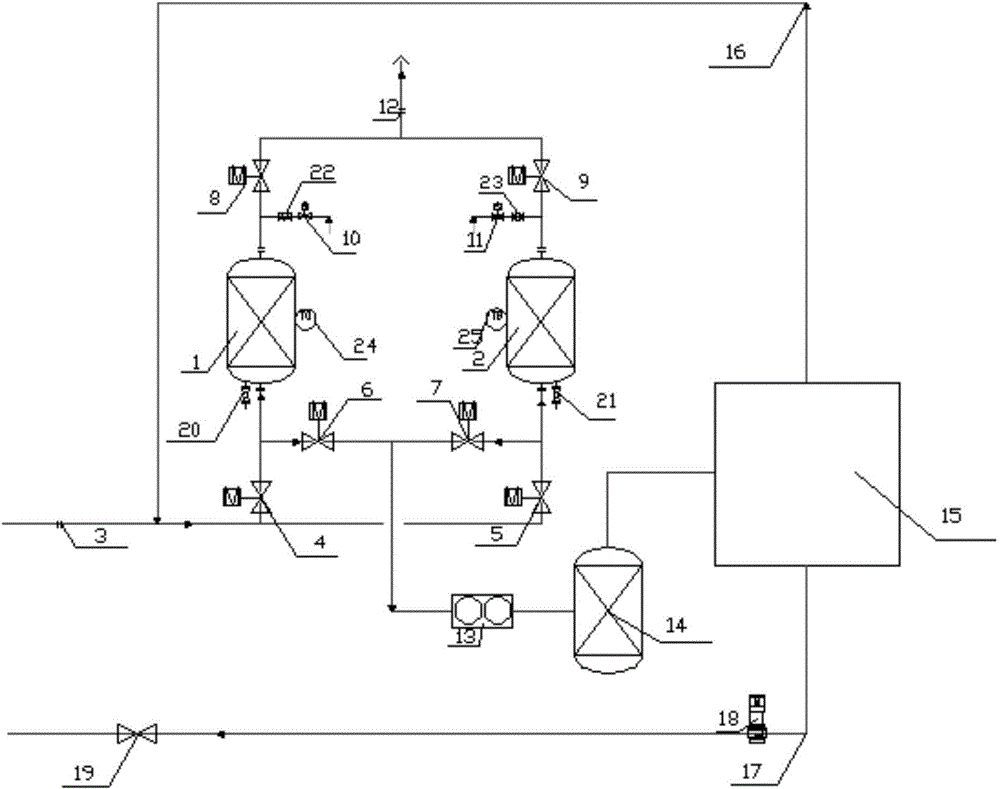

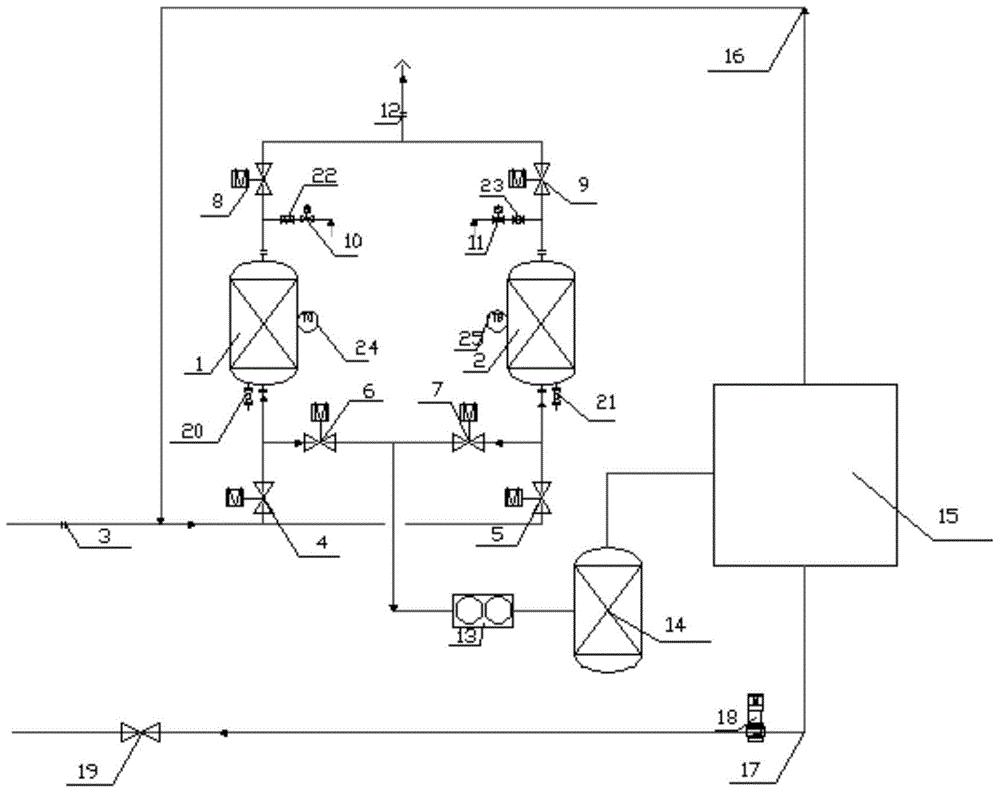

Passivation device of 'adsorption method' oil-gas recovery system

ActiveCN104436984AReduced adsorption activityImprove securityDispersed particle separationBuffer tankSorbent

The invention relates to a passivation device of an 'adsorption method' oil-gas recovery system to mainly solve the problem that the temperature is greatly raised in the prior art. According to the technical scheme of the invention, the passivation device of the 'adsorption method' oil-gas recovery system, provided by the invention, comprises at least two adsorption tanks, a vacuum pump, a condensing unit and a buffer tank, wherein a gas inlet pipeline, a passivation gas and inert gas inlet pipeline and a vacuumizing pipeline are arranged at the bottom of each adsorption tank respectively; outlet pipelines at the top of each adsorption tank are converged into a gas discharge pipeline; one end of the vacuumizing pipeline is connected with an inlet of the vacuum pump; an outlet of the vacuum pump is connected with the buffer tank; an outlet of the buffer tank is connected with an inlet of the condensing unit; a secondary return air pipeline arranged on the condensing unit is connected with a passivation gas inlet pipeline at the bottom of each adsorption tank; and a condensate conveying pipeline is also arranged at the lower part of the condensing unit. By adopting the technical scheme, the problem is well solved, and the passivation device can be used for passivation of an adsorbent of the oil-gas recovery system.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

Interlayer insulating placement structure for oil-immersed transformer

InactiveCN104779041ACompact structureReduce the amount usedTransformers/inductances coils/windings/connectionsMechanical engineeringTransformer windings

The invention relates to an interlayer insulating placement structure for an oil-immersed transformer. The interlayer insulating placement structure comprises transformer winding coils and cable paper, wherein at least three transformer winding coils are connected in series and are respectively distributed in parallel; a part between the transformer winding coils positioned on two sides of the structure is divided into at least three sections of structures with the same length; the transformer winding coils of all the sections are connected in series; all the transformer winding coils are separated by the cable paper; at least two pieces of cable paper are arranged. According to the interlayer insulating placement structure disclosed by the invention, the structure is compact; the use quantity of insulation paper is effectively reduced while operation performance of the transformer is guaranteed, so that on one hand, the effects of saving raw materials and reducing the cost of the transformer are realized, and on the other hand, the structure of the transformer is also effectively simplified, the size and dead weight are reduced, the temperature rise effect of the transformer during operation is reduced, the heat dissipating performance of the transformer is enhanced, and eventually the aim of improving the performance of the transformer is achieved.

Owner:华夏恒业智能电气有限公司

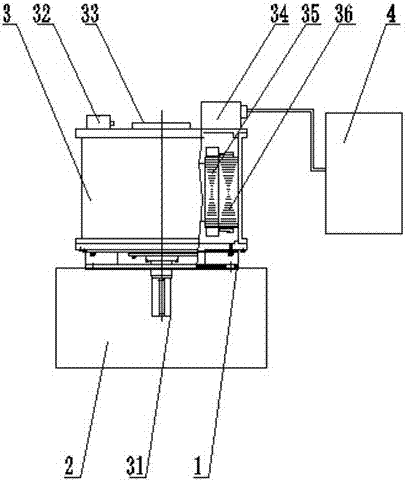

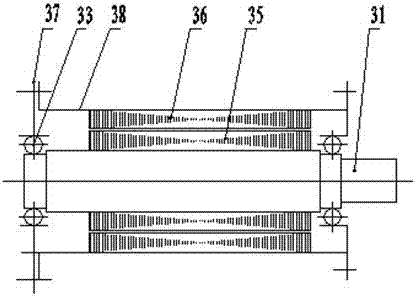

Segment type motor stator housing based on mechanical model and assembling design method thereof

PendingCN106655585ASimplify the assembly processImprove thermal performanceManufacturing dynamo-electric machinesSupports/enclosures/casingsHousing designEngineering

The invention relates to a segment type motor stator housing based on a mechanical model and an assembling design method thereof, thus solving the problems that an existing shrinkage fit technology has inconveniences in stator and housing installations; one end of the left half housing is provided with a bolt fixed seat A, the other end is provided with a bolt fixed seat B, and A and B are in mirror arrangement; one end of the right half housing is provided with a bolt fixed seat C, the other end is provided with a bolt fixed seat D, and C and D are in mirror arrangement; the left and right half housings are matched so as to clamp the outer side of the stator, and are in mirror arraignment; a left bolt is arranged on the bolt fixed seats A and C; a right bolt is arranged on the bolt fixed seats B and D. The segment type motor housing design is realized; the bolts can fix and mount the left and right half housings, thus greatly simplifying the motor stator housing assembling process.

Owner:HEFEI JUYI POWER SYST CO LTD

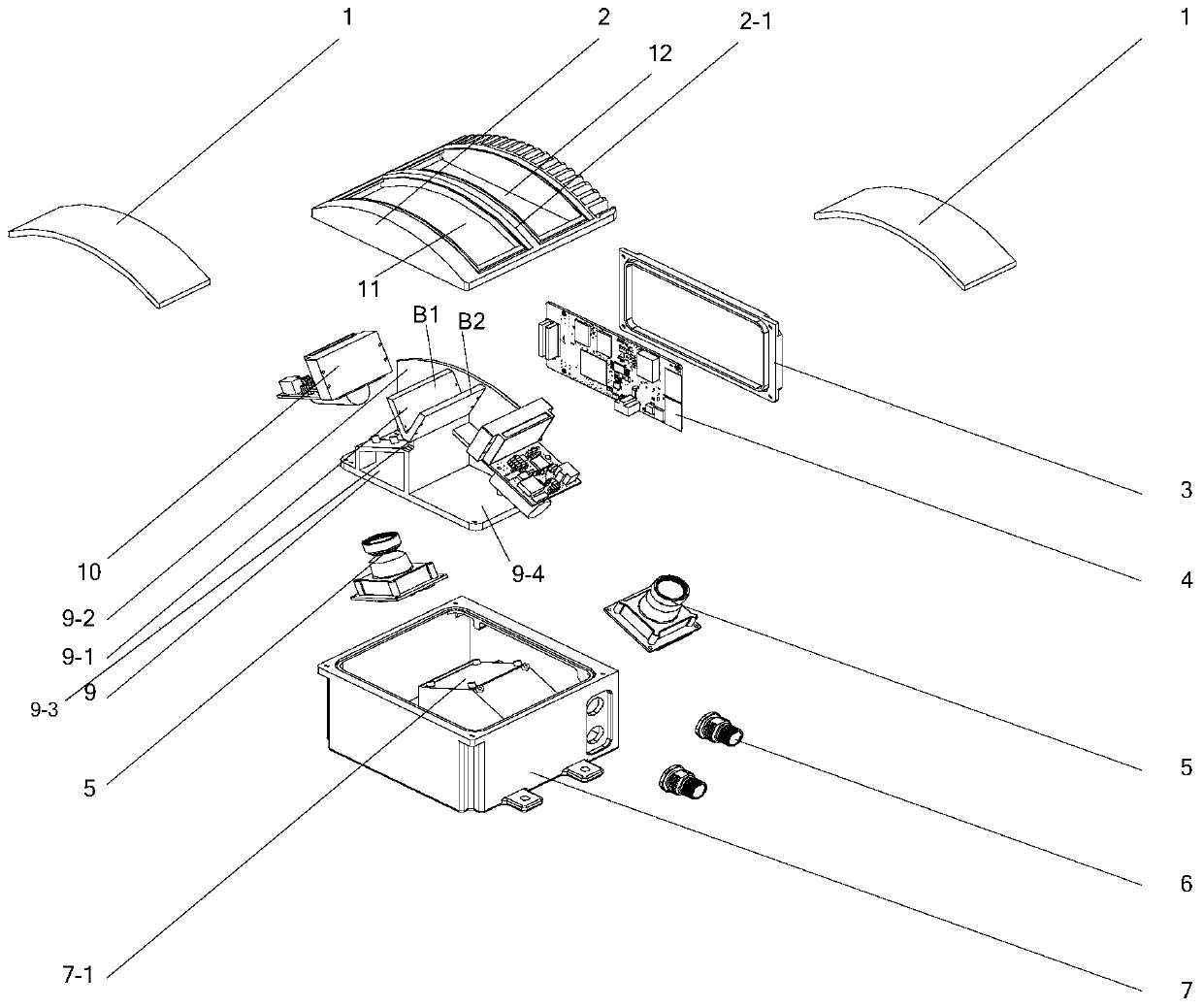

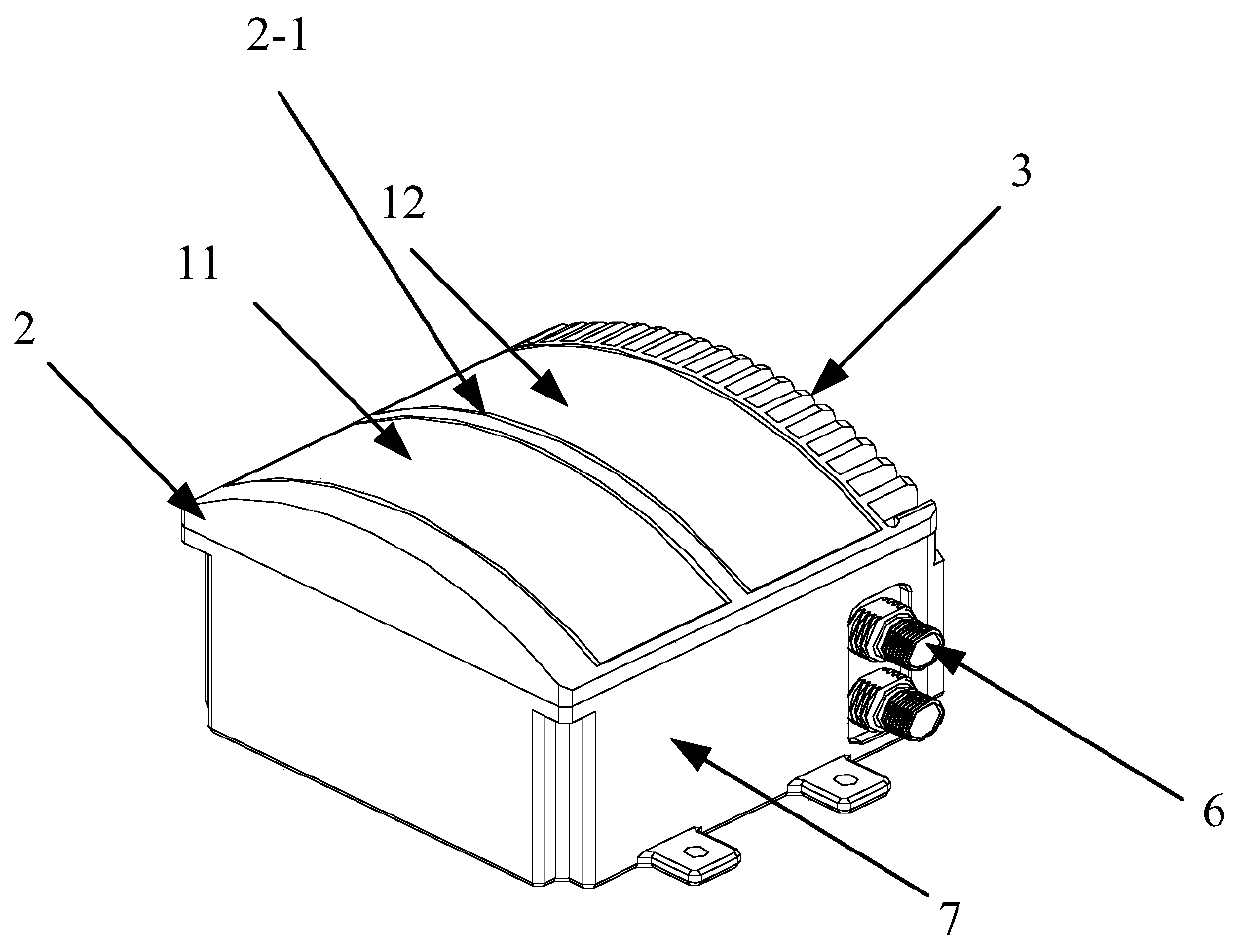

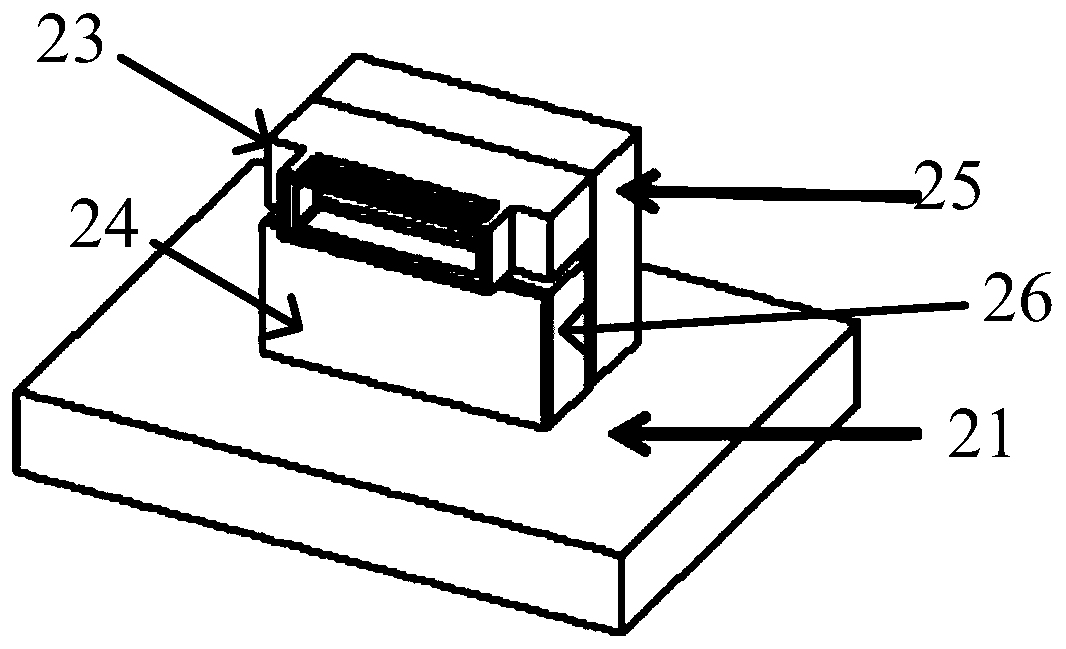

Depth camera

PendingCN110609300AReduce the effect of temperature riseImprove cooling efficiencyElectromagnetic wave reradiationCamera lensOptoelectronics

The invention provides a depth camera comprising a housing, a depth lens module and a laser module. The depth lens module and the laser module are arranged in the housing. The laser module is fixedlyinstalled on the bottom of the housing by a first bracket and includes a laser device, a laser circuit board, and a first heat-conduction base; the laser device and the laser circuit board are connected electrically; the first heat-conduction base has a first area for fixing the laser device and a second area for fixing a second first heat conduction base; a heat insulation layer is arranged between the second area and the second heat conduction base; and the surface, away from the second area, of the second heat conduction base is used for fixing the laser circuit board. The first heat conduction base and the second heat conduction base are respectively fixed with the first bracket. Therefore, the adverse effect of the laser circuit board on the heat dissipation effect of the laser in thelaser module is eliminated.

Owner:HANGZHOU GUANGPO INTELLIGENT TECH CO LTD

Passivation device for "adsorption method" oil and gas recovery system

ActiveCN104436984BReduced adsorption activityImprove securityDispersed particle separationSorbentBuffer tank

The invention relates to a passivation device of an 'adsorption method' oil-gas recovery system to mainly solve the problem that the temperature is greatly raised in the prior art. According to the technical scheme of the invention, the passivation device of the 'adsorption method' oil-gas recovery system, provided by the invention, comprises at least two adsorption tanks, a vacuum pump, a condensing unit and a buffer tank, wherein a gas inlet pipeline, a passivation gas and inert gas inlet pipeline and a vacuumizing pipeline are arranged at the bottom of each adsorption tank respectively; outlet pipelines at the top of each adsorption tank are converged into a gas discharge pipeline; one end of the vacuumizing pipeline is connected with an inlet of the vacuum pump; an outlet of the vacuum pump is connected with the buffer tank; an outlet of the buffer tank is connected with an inlet of the condensing unit; a secondary return air pipeline arranged on the condensing unit is connected with a passivation gas inlet pipeline at the bottom of each adsorption tank; and a condensate conveying pipeline is also arranged at the lower part of the condensing unit. By adopting the technical scheme, the problem is well solved, and the passivation device can be used for passivation of an adsorbent of the oil-gas recovery system.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

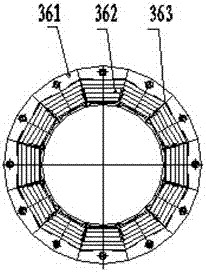

Cement powder concentrator power assembly and low-speed high-torque amorphous permanent magnet motor thereof

InactiveCN108011458AReduce reactive power lossReduce the effect of temperature riseWindings insulation shape/form/constructionMagnetic circuit rotating partsPowertrainHigh torque

The invention discloses a cement powder concentrator power assembly, relates to the technical field of grading equipment of non-metallic ore powder, and particularly belongs to a cement powder concentrator power assembly and a low-speed high-torque amorphous permanent magnet motor adopted by the power assembly. The cement powder concentrator power assembly is characterized by comprising a mountingbase arranged at the top end of the powder concentrator; the low-speed high-torque amorphous permanent magnet motor is vertically connected with the mounting base; the output shaft of the low-speed high-torque amorphous permanent magnet motor is directly connected with a powder concentrator fan; and a frequency conversion speed regulation control cabinet is connected with the low-speed high-torque amorphous permanent magnet motor. By virtue of the cement powder concentrator power assembly, reactive loss of the motor is lowered, and the motor temperature rise effect can be obviously lowered; compared with the existing permanent magnet motor, the permanent magnet motor disclosed in the invention can save energy by 10-20% provided by detection , so that the motor size can be reduced, the occupied space can be reduced, and the driving assembly is more stable in performance; and by adopting a remote control frequency conversion technology, intelligent operation control is realized.

Owner:日照东方电机有限公司

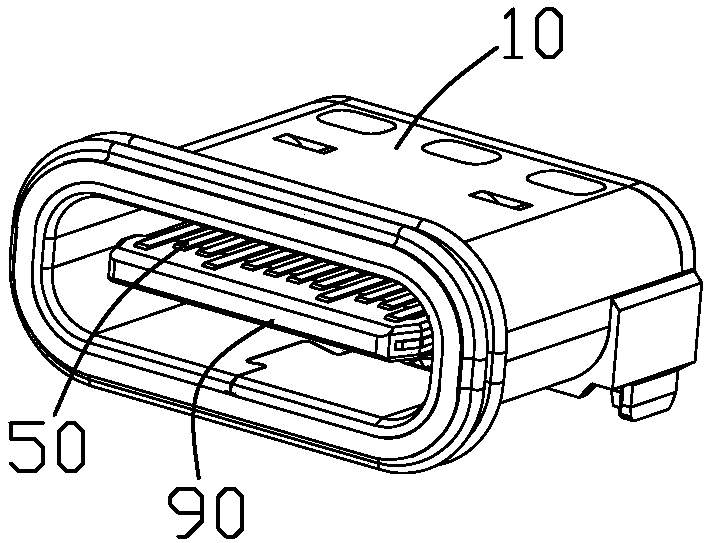

Reversely insert usb socket

ActiveCN106058581BReduce the effect of temperature riseNo short circuit problemCoupling contact membersCoupling protective earth/shielding arrangementsUSBEmbedded system

The invention discloses a pro and con-pluggable USB socket, which comprises a metal middle board, a first terminal group and a second terminal group symmetrically located at two vertical sides of the metal middle board respectively, and an insulated body for enabling the first terminal group and the second terminal group and the metal middle board to be formed as a whole, wherein the first terminal group and the second terminal group comprise two first grounding terminals and two second grounding terminals located at the outermost side, a plurality of first signal terminals and two first power terminals located between the two first grounding terminals and a plurality of second signal terminals and two second power terminals located between the two second grounding terminals; the metal middle board between the first signal terminals and the first power terminals of the first terminal group and the second signal terminals and the second power terminals of the second terminal group is removed; and the metal middle board is only located between the first grounding terminals and the second grounding terminals. The pro and con-pluggable USB socket can effectively support high-current charging.

Owner:SHENZHEN EVERWIN PRECISION TECH

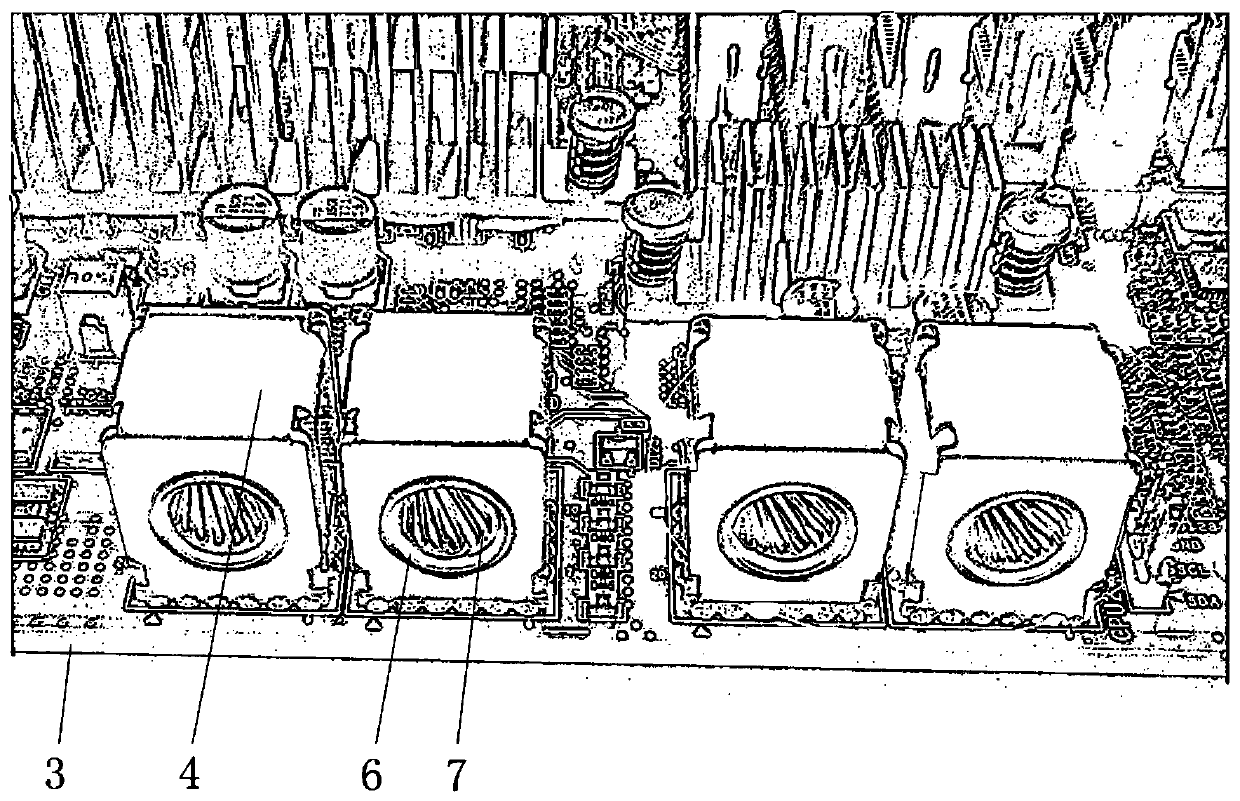

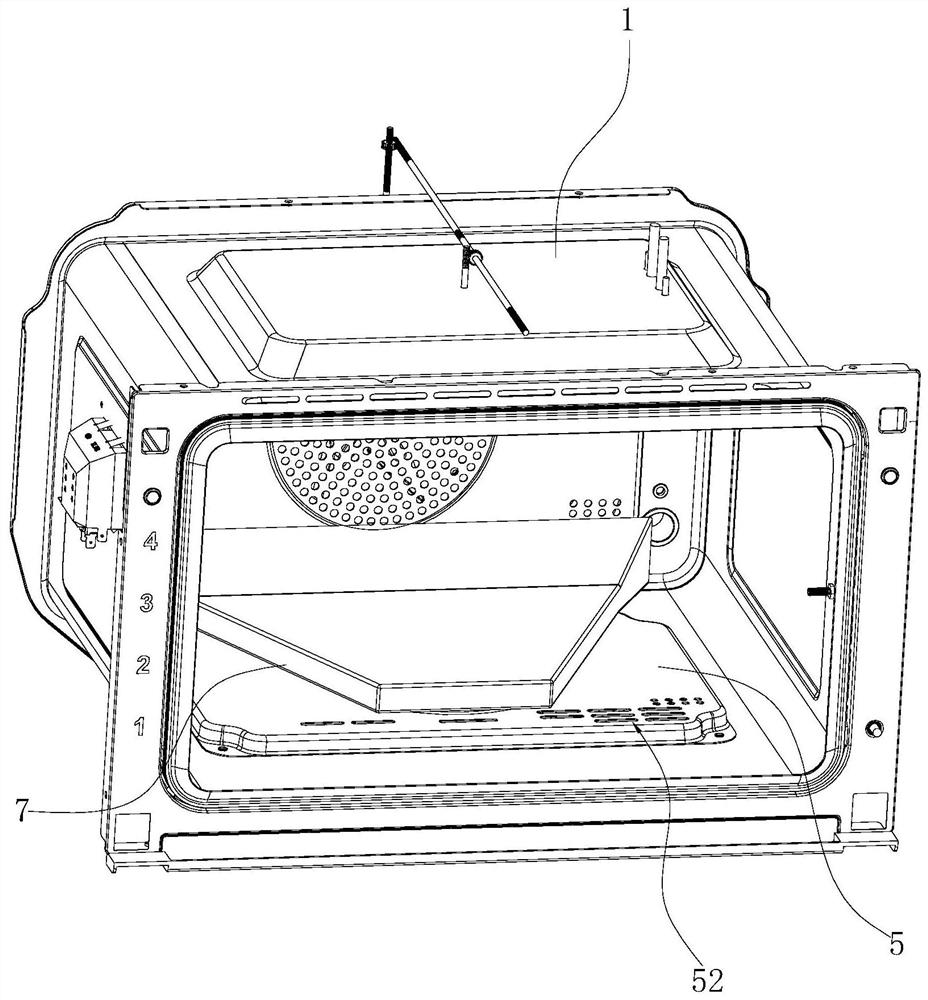

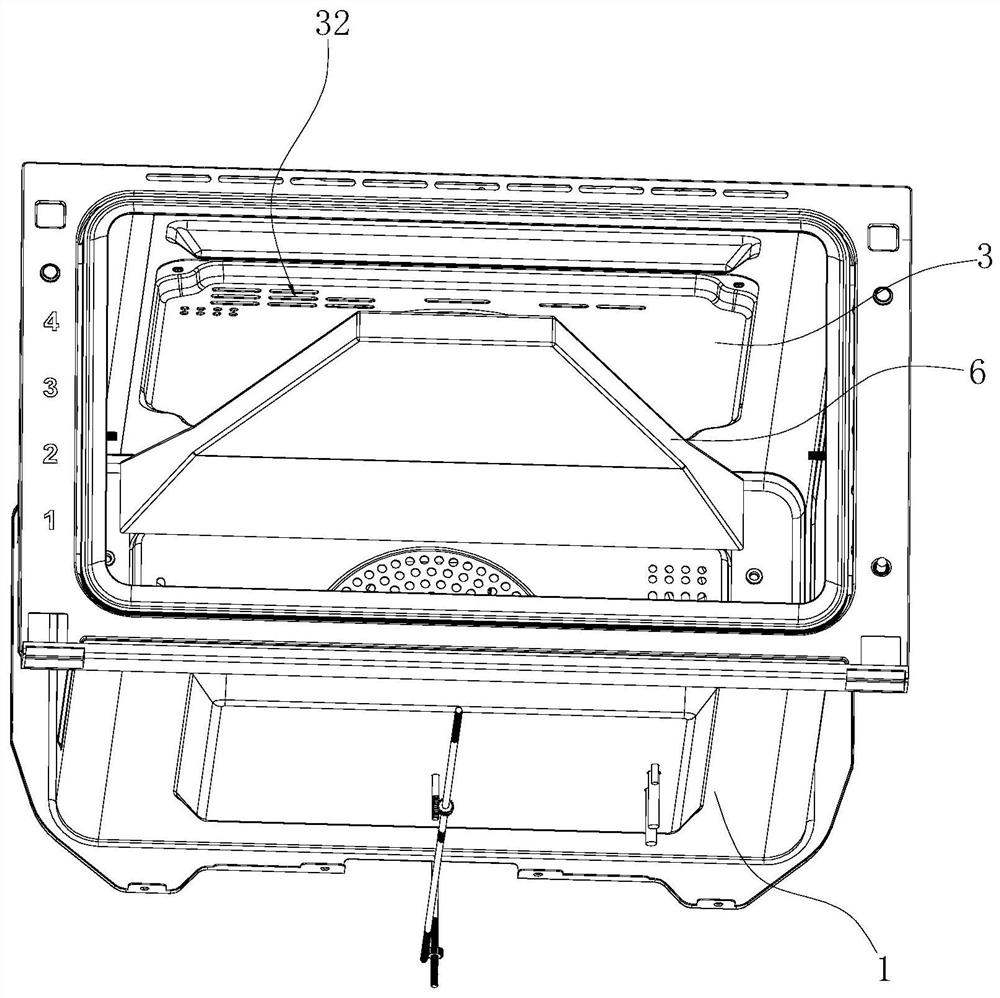

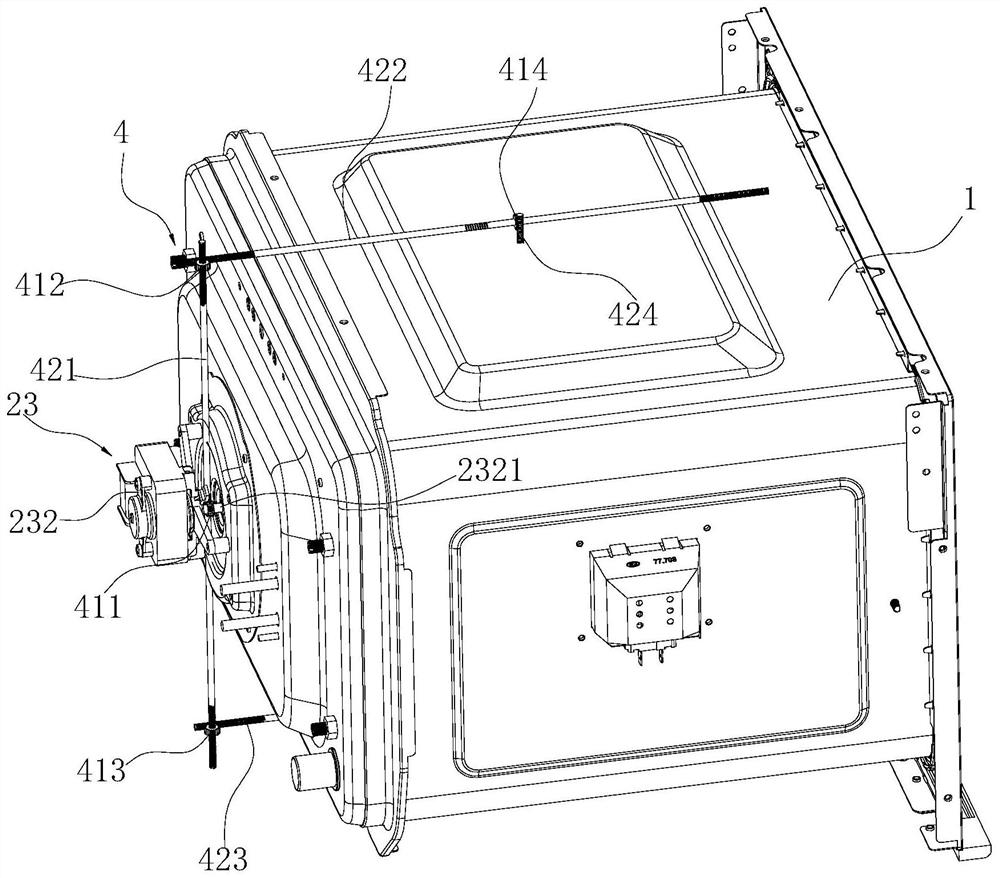

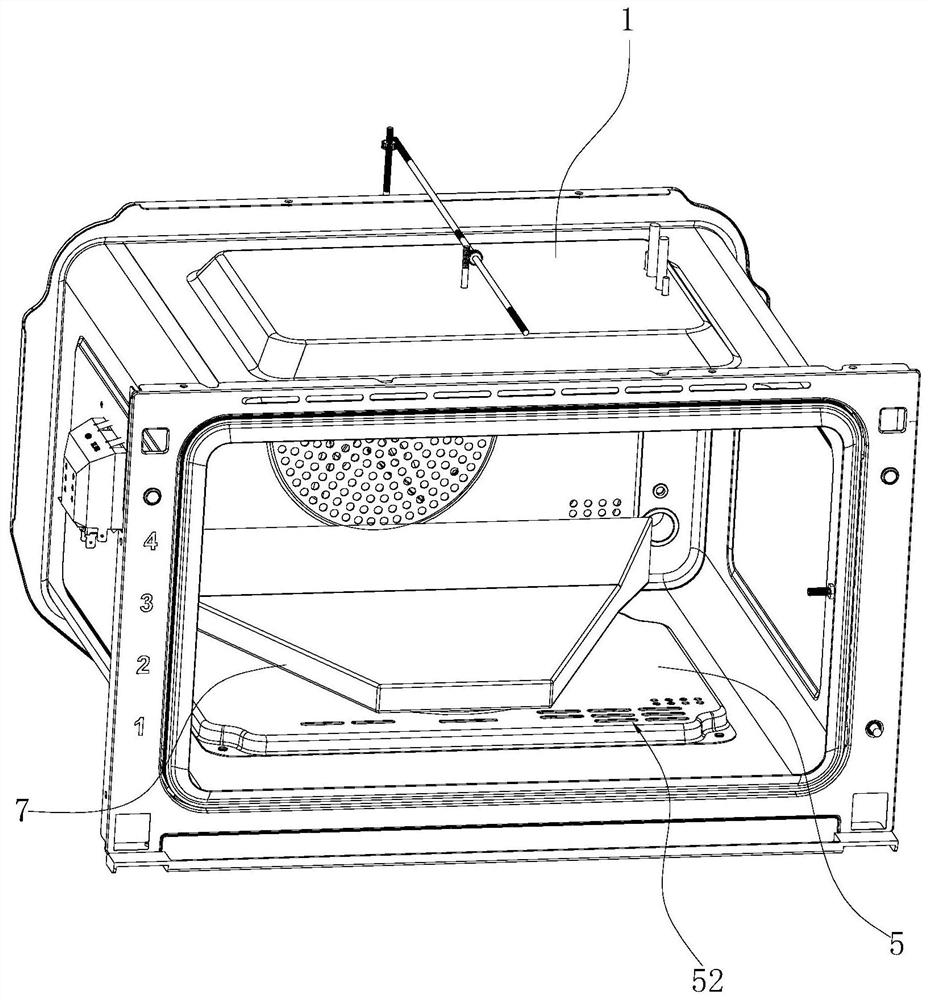

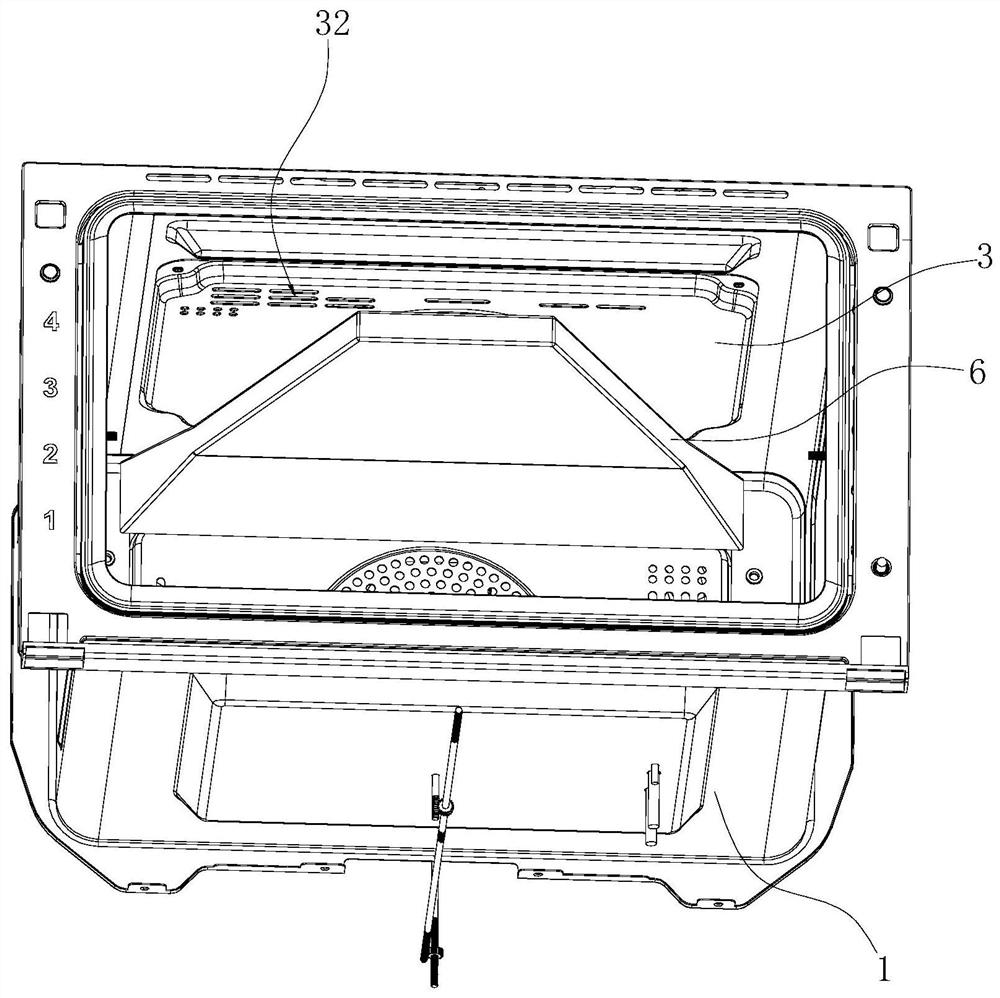

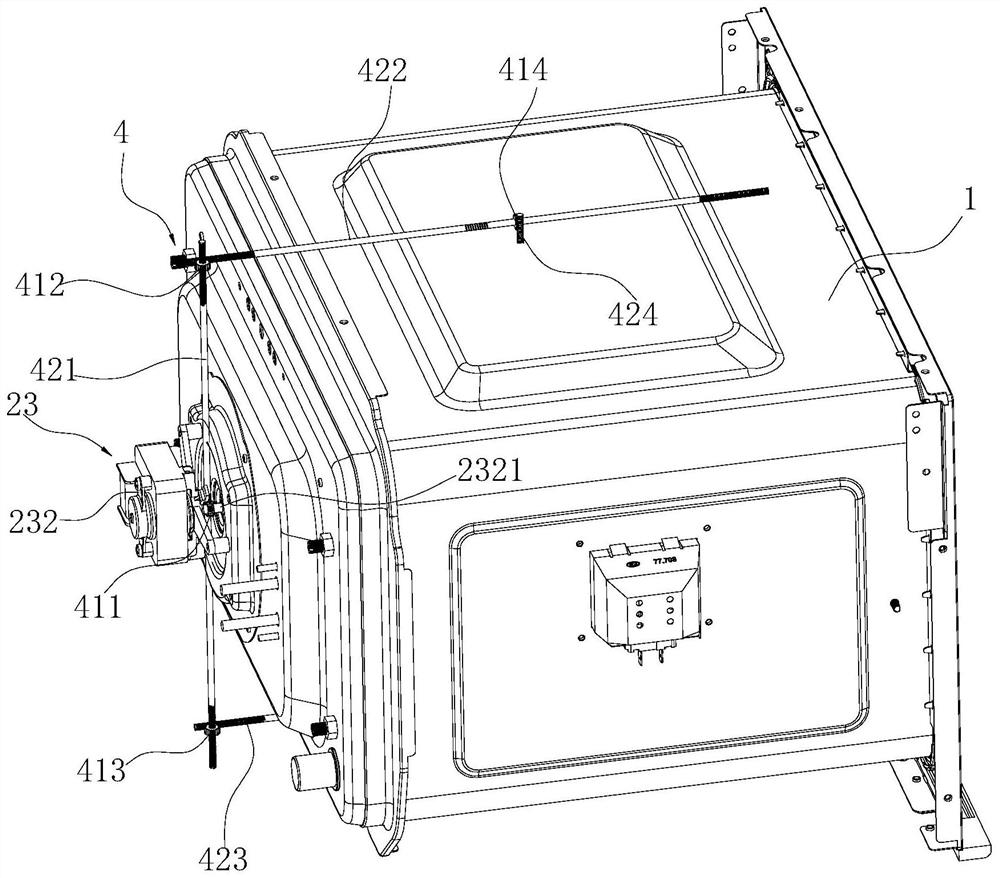

Hot air structure with air frying function and oven

ActiveCN112493874AHeating up fastImprove the uniformity of the temperature fieldRoasters/grillsThermodynamicsEngineering

According to a hot air heating structure with the air frying function and an oven, a back hot air chamber, a top hot air chamber and a bottom hot air chamber are arranged in an inner container, and outlet air of the back hot air chamber can enter the top hot air chamber and the bottom hot air chamber; therefore, the speed is increased through the top hot air fan blades in the top hot air chamber and the bottom hot air fan blades in the bottom hot air chamber, and meanwhile reheating is achieved through the top heating pipe in the top hot air chamber and the bottom heating pipe in the bottom hot air chamber. And air flow accelerated and reheated by the top hot air chamber and the bottom hot air chamber forms high-speed hot air circulation in the liner under the action of suction force at the first air inlet of the back hot air chamber, so that rapid heating of the liner is realized, and the requirement of an air frying function on rapid heating is met. In addition, the back hot air chamber, the top hot air chamber and the bottom hot air chamber conduct heating at the same time, and the temperature field uniformity of the inner container can be improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

High-current usb Type C socket and manufacturing method thereof

ActiveCN106252932BLower impedanceEnhanced current flowContact member manufacturingContact member assembly/disassemblyEngineeringUSB

Provided is a large-current USB Type C type socket, which comprises a metal middle plate provided with a main body portion; a first terminal group and a second terminal group, which are symmetrically arranged at the upper and lower sides of the metal middle plate; and an insulation body for enabling the first and second terminal groups to be integrated with the metal middle plate. The first terminal group comprises two outermost first grounding terminals, a plurality of first signal terminals, which are arranged between the two first grounding terminals, and two first power terminals; and a second terminal group comprises two outermost second grounding terminals, a plurality of second signal terminals, which are arranged between the two second grounding terminals, and two second power terminals. The thickness of the first power terminal and the thickness of the second power terminal are larger than the thickness of the first signal terminal and the thickness of the second signal terminal respectively; the main body portion of the metal middle plate is provided with strip holes in the positions corresponding to the first power terminals and the second power terminals respectively. The large-current USB Type C type socket can effectively support large-current charging.

Owner:SHENZHEN EVERWIN PRECISION TECH

A hot air structure and oven with air frying function

ActiveCN112493874BHeating up fastImprove the uniformity of the temperature fieldRoasters/grillsThermodynamicsEngineering

The invention relates to a hot air heating structure with air frying function and an oven. The inner container is respectively provided with a back hot air chamber, a top hot air chamber and a bottom hot air chamber, wherein the air from the back hot air chamber can enter the bottom hot air chamber and the bottom hot air chamber respectively. so that the speed increase is achieved by the top hot blast fan blades in the top hot blast chamber and the bottom hot blast fan blades in the bottom hot blast chamber while reheating is achieved by the top heating tubes in the top hot blast chamber and the bottom heating tubes in the bottom hot blast chamber, and The speed-up and reheated airflow through the top hot air chamber and bottom hot air chamber forms a high-speed hot air circulation in the inner tank under the action of the suction force at the first air inlet of the back hot air chamber, so as to realize the rapid heating of the inner tank and meet the requirements of air frying. Functional requirements for rapid heating. In addition, the simultaneous heating of the back hot air chamber, the top hot air chamber and the bottom hot air chamber of the present invention can improve the uniformity of the temperature field of the inner tank.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Intensive metal trunk line of heat conduction structure

InactiveCN112768135AIncrease ampacityImprove cooling effectInsulated cablesInsulated conductorsMetallic enclosureElectrical conductor

The invention discloses an intensive metal trunk line with a heat conduction structure in the technical field of power transmission and distribution metal trunk line conductor structures. The intensive metal trunk line adopts an ultra-thin good thermal conductor to deeply wrap each strand of conductor material which can be divided; the ultra-thin good thermal conductor is in direct contact with the metal shell to conduct and dissipate heat; full-length wrapping or partial wrapping is carried out on the conductor materials by using the ultra-thin good thermal conductor according to the product requirement; and the ultra-thin good thermal conductor and the metal shell are fixed through screws or rivets to avoid sliding. According to the intensive metal trunk line, the ultra-thin good thermal conductor is used for penetrating into the metal conductor to conduct temperature rise in time, so that the heat conduction efficiency of the temperature rise effect in the metal conductor is greatly improved, the heat dissipation capability of the metal trunk line is remarkably improved, the temperature rise effect of the metal trunk line is reduced, and the current-carrying capacity of the conductor is obviously improved.

Owner:杨柳

High current usb Type C socket

ActiveCN106252933BLower impedanceEnhanced current flowCoupling contact membersCoupling protective earth/shielding arrangementsUSBHigh current

A high-current USB Type C socket, comprising a metal middle plate provided with a main body, a symmetrical first terminal group and a second terminal group respectively located on the upper and lower sides of the metal middle plate, and the first and second terminal groups Two terminal groups and the metal middle plate are integrally formed into an insulating body, the first and second terminal groups respectively include two first ground terminals and two second ground terminals located on the outermost sides, and two ground terminals located at the two Several first signal terminals and two first power supply terminals between the first ground terminals, and several second signal terminals and two second power supply terminals located between the two second ground terminals, the first , the thickness of the second power terminal is greater than the thickness of the first and second signal terminals, and the main body of the metal middle plate is provided with strip-shaped holes at positions corresponding to the first and second power terminals; the present application The high-current USB Type C socket can effectively support high-current charging.

Owner:SHENZHEN EVERWIN PRECISION TECH

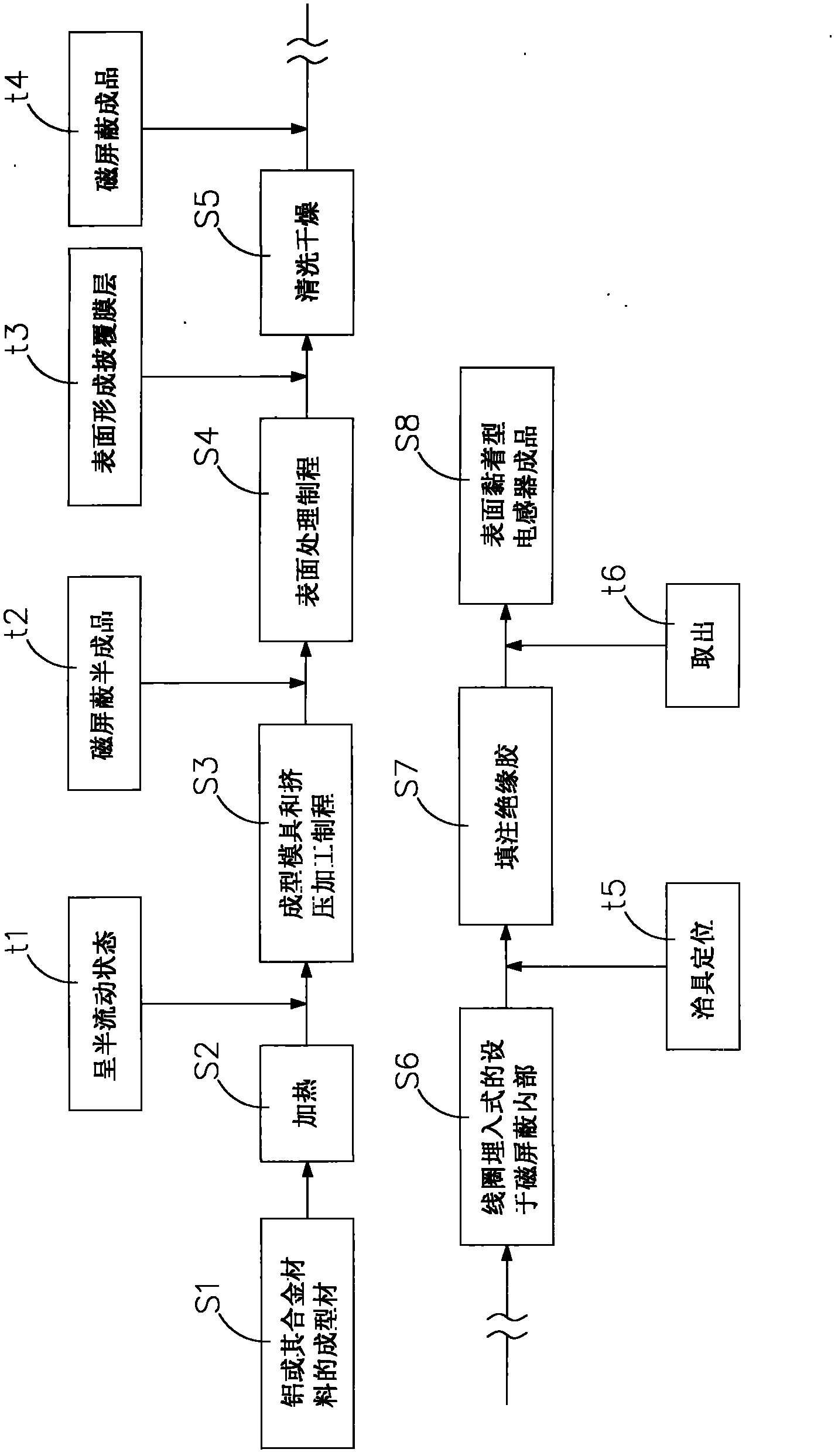

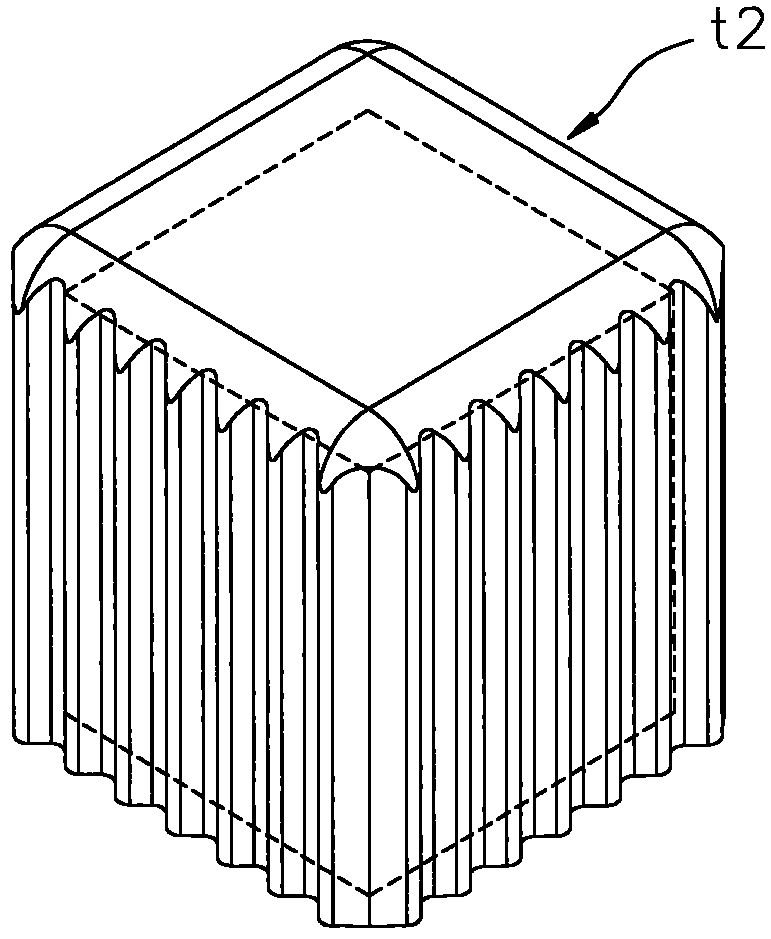

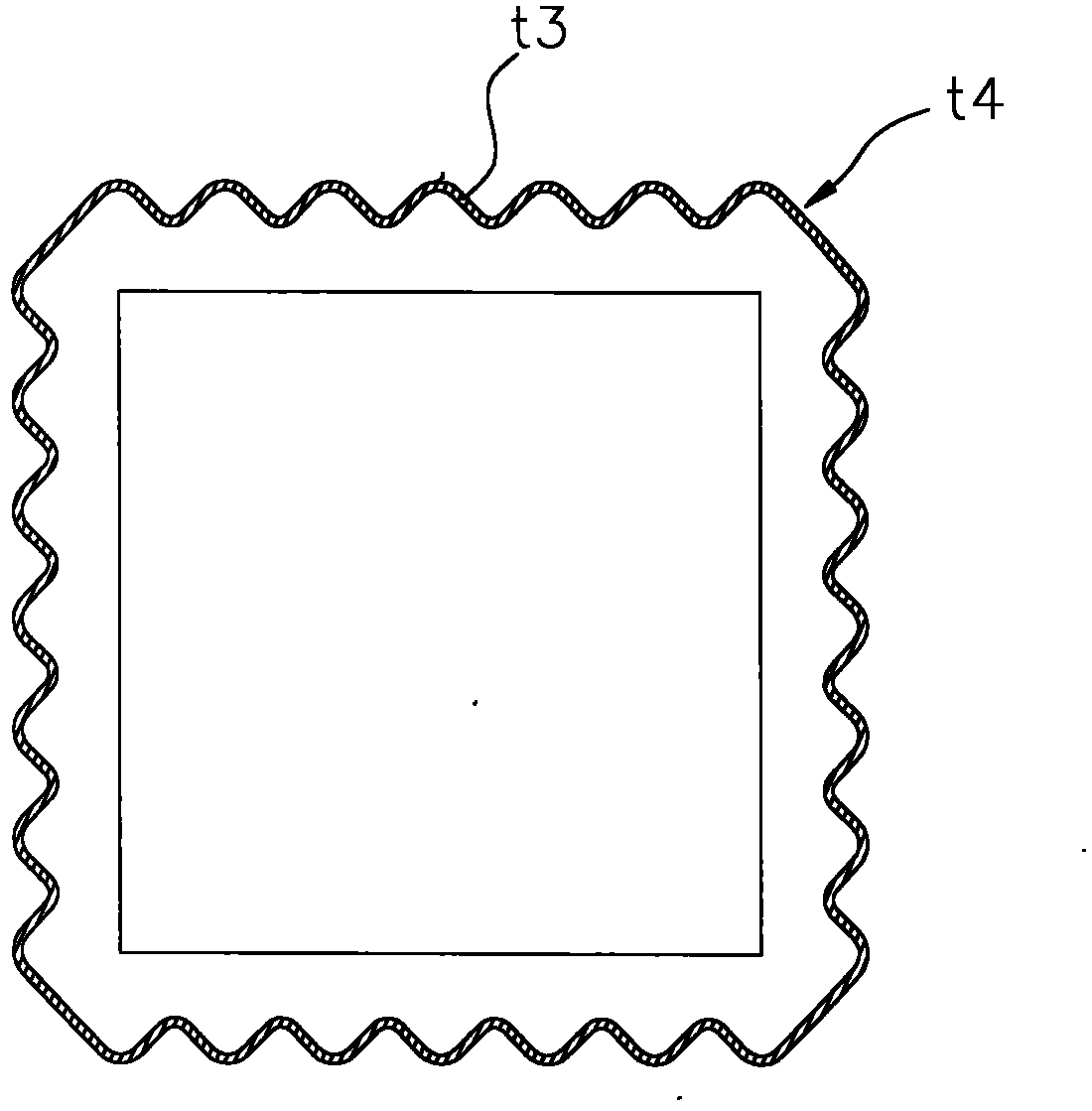

Manufacturing method of aluminum or aluminium alloy forming surface adhesion-type inductor and structure thereof

InactiveCN103165279AInsulationAnti-foulingMagnetic/electric field screeningInductances/transformers/magnets manufactureInductorSurface finishing

The invention discloses a manufacturing method of an aluminum or aluminium alloy forming surface adhesion-type inductor and a structure of the aluminum or aluminium alloy forming surface adhesion-type inductor. Aluminum or aluminium alloy serves as forming materials, the forming materials present half flow condition after the forming materials are heated, and a magnetic shielding semi-finished product which is provided with a containing groove is finished by a forming die and an extrusion processing procedure; through a surface treatment procedure, a coating film layer is formed on the surface of the cooled magnetic shielding semi-finished product, and a magnetic shielding semi-finished product is obtained after the cooled magnetic shielding semi-finished product is cleaned and died, a coil is provided, the coil contains an iron core, the iron core is arranged in a hollow part of the coil, and moldings extend from two sides of the coil in a centrifugal line mode; the coil which contains the iron core is arranged in a magnetic shielding in an embedded-type mode, and parts of the moldings are exposed out of the magnetic shielding, insulation paste is filled in a space in the containing groove of the magnetic shielding to flat parts which are protruded from the magnetic shielding to enable the moldings to be exposed out to form a surface adhesion-type inductor finished product. By the adoption of the manufacturing method of the aluminum or aluminium alloy forming surface adhesion-type inductor and the structure of the aluminum or aluminium alloy forming surface adhesion-type inductor, manufacture procedures of the surface adhesion-type inductor finished product are simplified, and a good promotion of efficiency of heat dissipation is provided.

Owner:黄浩洲 +2

A kind of pvc composite floor with anti-slip and wear-resistant high-permeability surface layer structure

ActiveCN104947914BHigh light transmittanceImprove toughnessSynthetic resin layered productsCoatingsFiberHigh density

The invention discloses an anti-slip and anti-wear PVC composite floor with a high-transmittance surface structure. The PVC composite floor includes a PVC panel and a bottom glue layer, wherein a waterproof insulating layer is arranged between the PVC panel and the bottom glue layer; the upper surface of the PVC panel is covered with a high-density anti-wear layer; the upper surface of the high-density anti-wear layer is coated with a high-transmittance surface layer; grooves are formed in the upper surface of the PVC panel; carbon fiber strips are arranged in the grooves. The PVC composite floor designed by the invention is firm and durable, simple in laying, anti-slip and anti-wear, and long in service life.

Owner:JIANGSU RUISHENG NEW MATERIALS CO LTD

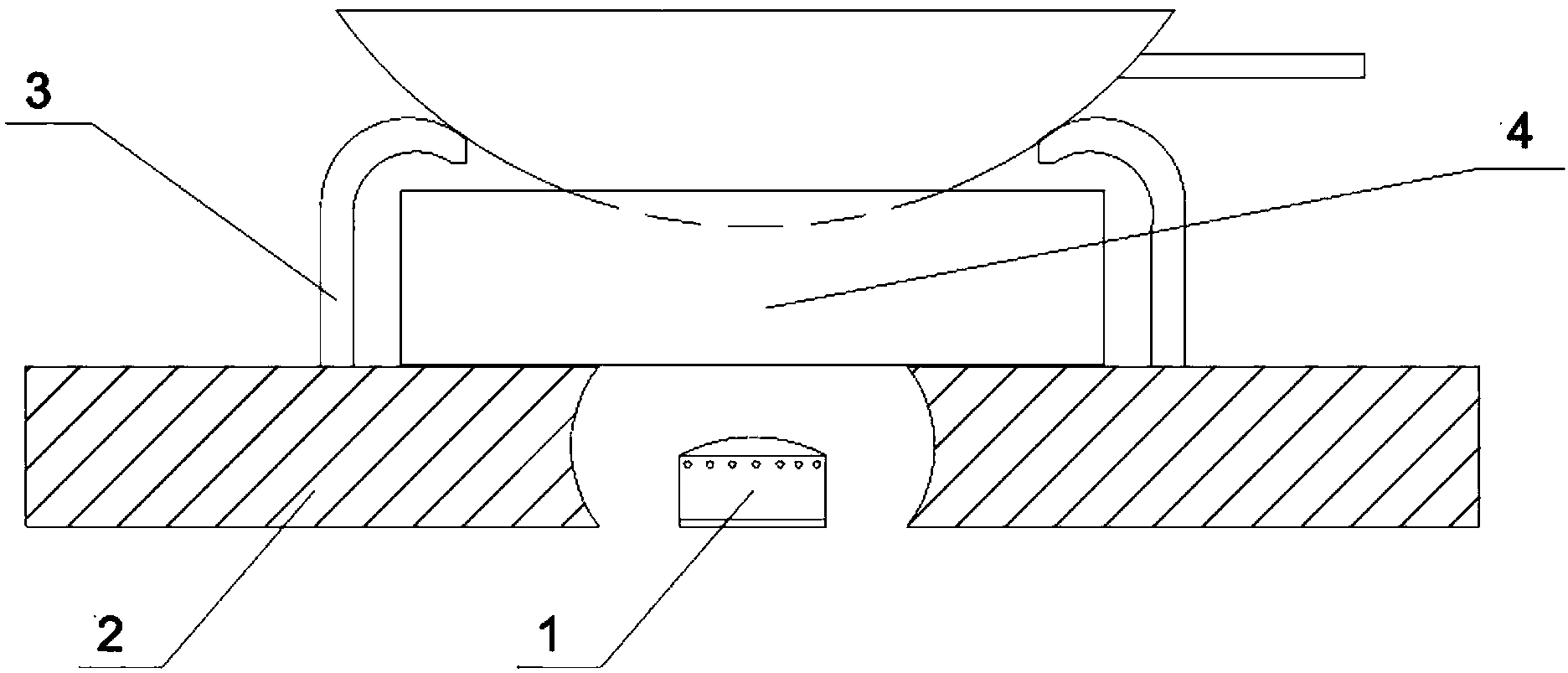

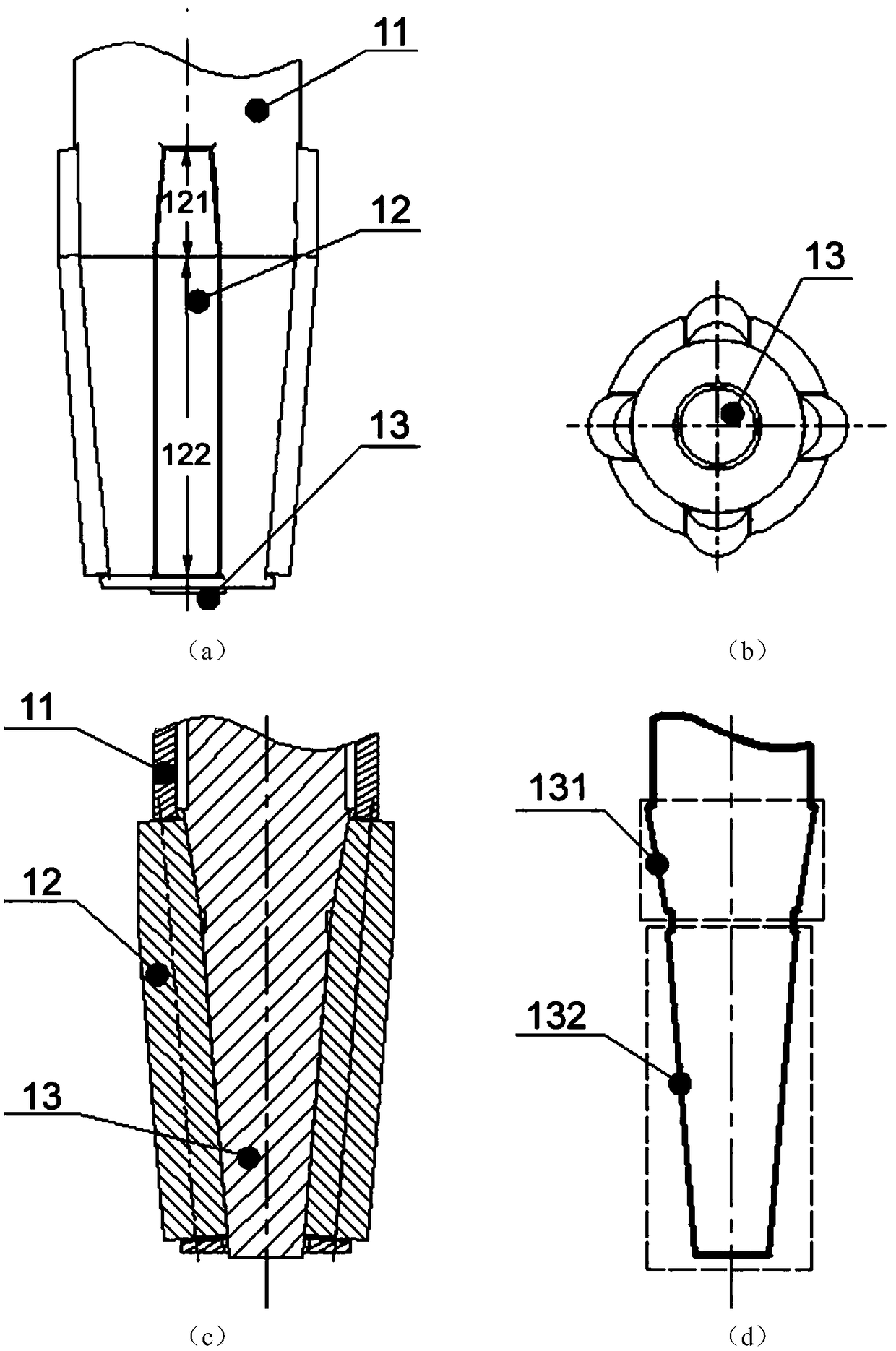

Apparatus and method for outwardly turning straight-side holes on hollow closed parts with complex curved surfaces

The invention discloses a device and method for flanging a straight flange hole outwards in a complicated curved surface hollow closed part and belongs to the technical field of precision forming of plate and pipe parts. The device comprises a needle bush, rolling needles and a central spindle. The central spindle is driven by a machine tool to conduct automatic rotation and axial feeding. The central spindle drives the needle bush and the rolling needles to rotate with the central spindle as the center. Meanwhile, the rolling needles rotate automatically under the action of friction force of the central spindle and the hole wall of the part. The needle bush, the rolling needles and the central spindle cooperate mutually to flange the hole in a preformed protrusion of the part. During hole flanging, firstly, the protrusion is preformed on the part; secondly, a hole flanging device is gradually pressed into the preformed hole to flange a material to be machined; and finally, the hole flanging process is completed through sizing and shape correcting. The hole flanging device is simple; the technological difficulty of flanging the straight flange hole outwards in the hollow closed part is effectively lowered; the friction force between the device and the part is little; the dimensional precision of hole flanging is high; and the edge of the flanged hole can be effectively prevented from cracking.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com