Primary permanent magnet linear motor actuator

A permanent magnet linear motor and actuator technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of easy burning of armature coils, irreversible demagnetization, permanent magnet overheating, etc., to avoid irreversible demagnetization and simple structure. , the effect of improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

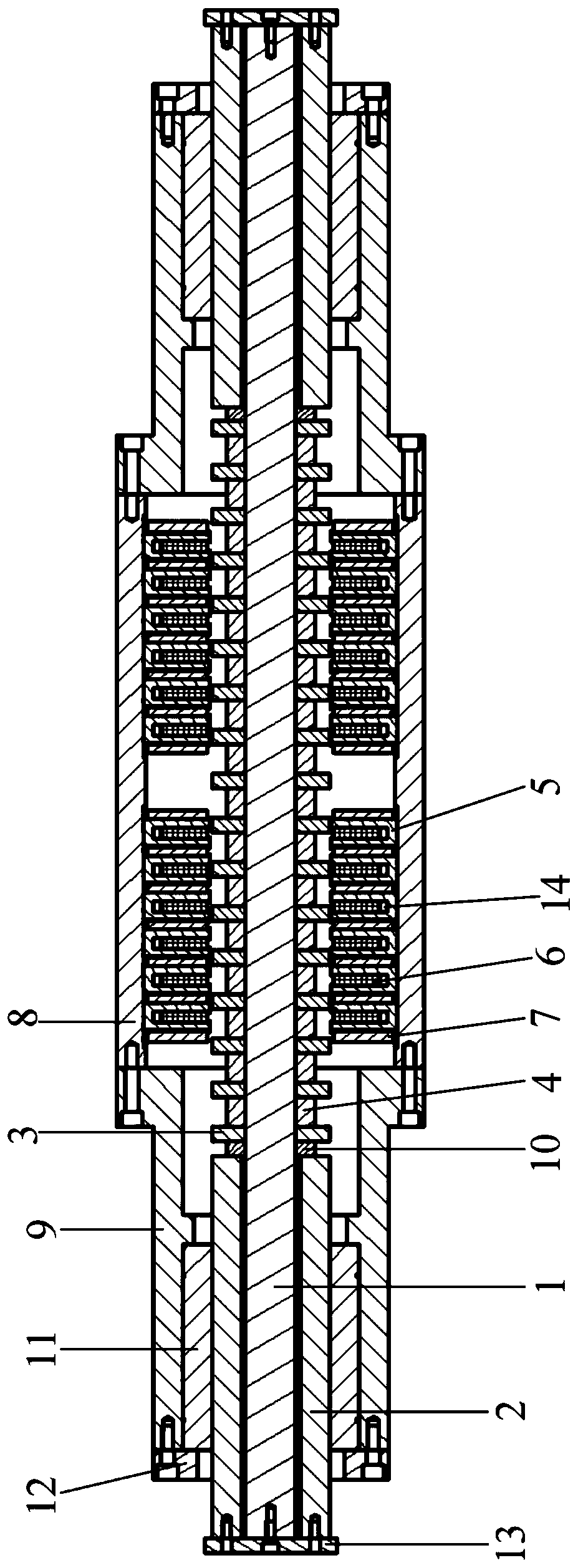

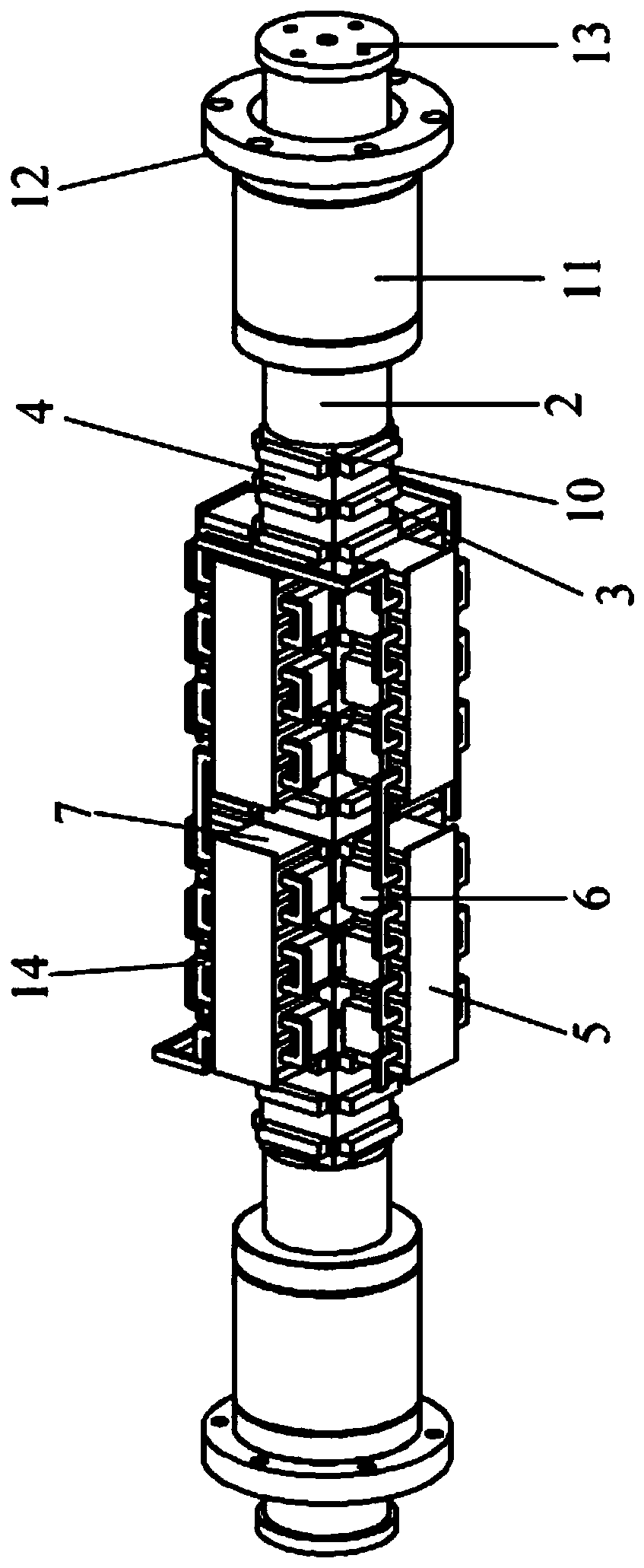

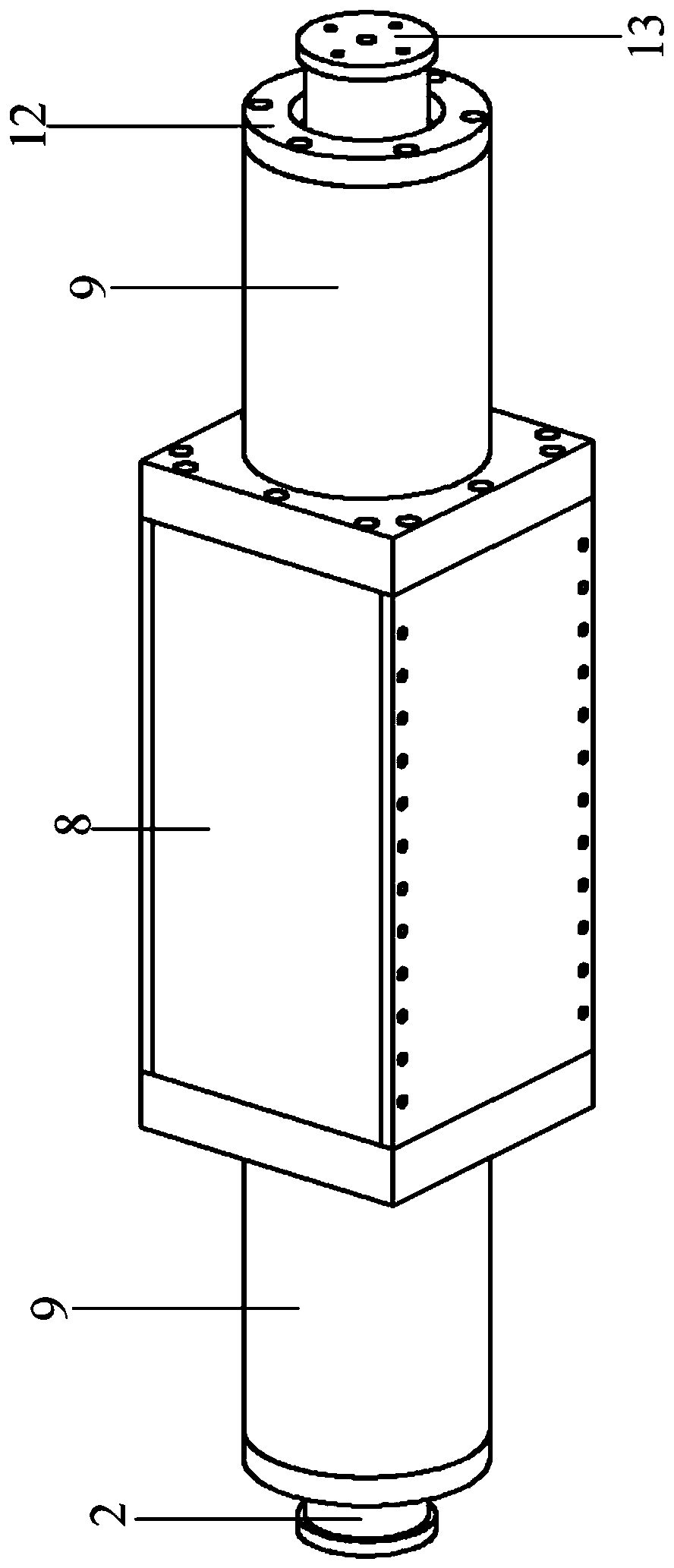

[0024] Below in conjunction with accompanying drawing, the composition structure of a kind of primary permanent magnet linear motor actuator of the present invention is described in detail:

[0025] see figure 1 , a primary permanent magnet linear motor actuator, including a drive shaft 1, a secondary mover convex tooth block 3, a secondary mover slot block 4, a primary stator core 5, an armature winding 6 and a permanent magnet 7; The drive shaft 1 is provided with a secondary mover of the primary permanent magnet linear motor, and the secondary mover is composed of a secondary mover convex tooth block 3 and a secondary mover groove block 4 placed at intervals along the axial direction of the drive shaft 1 ; The outer side of the drive shaft 1 is respectively symmetrically provided with four primary stators of the primary permanent magnet linear motor, see Figure 6 , the drive shaft is a cylindrical surface, but the drive shaft is equipped with a square-shaped secondary mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com